BS EN 10219 Cold Formed Welded Structural Hollow Sections

What is EN 10219?

BS EN 10219-2:2006 Cold formed welded structural hollow sections of non-alloy and fine grain steels.

EN 10219-1 Cold formed welded structural hollow sections of non-alloy and fine grain steels - Part 1: Technical delivery conditions - This part of this European Standard specifies the technical delivery conditions for cold formed welded structural hollow sections of circular, square or rectangular forms and applies to structural hollow sections formed cold without subsequent heat treatment.

Classification

Grade classification

|

Non-alloy Steel Grade |

S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

|

Fine-grain steel Grade |

S275NH, S275NLH, S355NH, S355NLH, S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH |

Material classification

Carbon steel: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH;

Special alloy steel: S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH;

Section shape classification

CFCHS: Circular;

CFRHS: Square or Rectangular;

CFEHS: Elliptical;

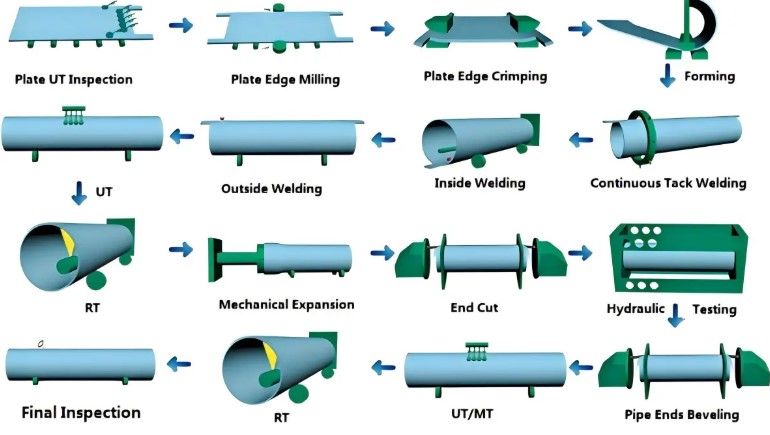

Manufacturing process

According to EN 10219, the hollow sections are produced by either electric welding or submerged arc welding, without the need for subsequent heat treatment.

Electric welding is typically applied in the production of ERW (Electric Resistance Welded) and EFW (Electric Fusion Welded) pipes, which feature high production efficiency and uniform weld quality. On the other hand, submerged arc welding (SAW)—including LSAW (SAWL), SSAW (HSAW), and DSAW—is mainly used for larger-diameter and thicker-walled structural tubes, offering deep weld penetration and excellent mechanical strength.

In general, electric-welded hollow sections are delivered without internal weld bead trimming, as this does not affect their mechanical performance or dimensional accuracy in most structural applications.

Outer dimensions and wall thickness

The outer dimensions of hollow sections vary according to their shape. Circular sections can reach diameters of up to 2500 mm, while square sections are available up to 500 mm × 500 mm and rectangular sections up to 500 mm × 300 mm. Elliptical sections can be manufactured with maximum dimensions of 480 mm × 240 mm, providing flexibility for diverse structural applications.

The wall thickness of these sections can be produced up to 40 mm, allowing them to meet a wide range of strength and load-bearing requirements.

The tolerances on dimensions are established in accordance with EN 10219-1&2

| Characteristics | Tolerances | ||||

| Outside dimensions of side |

(H,B |

|

|||

|

H : Longest side B : Shortest side |

(100mm |

|

|||

|

(200mm |

|

||||

| Wall thickness(T) |

(T |

|

|||

|

(5mm |

|

||||

| Concavity / Convexity | MAX 0.8% with a min of 0.5mm | ||||

| Squareness of sides |

90 |

||||

| External corner radius |

(T |

1.6T |

|||

|

(6mm |

2.0T |

||||

|

(10mm |

2.4T |

||||

| Twist | 2mm + 0.5mm/m in length | ||||

| Straightness | 0.15% in total length | ||||

| Mass |

|

||||

| Length | Approximate | 0, +50mm | |||

| Exact |

L |

0, +5mm | |||

|

6,000mm |

0, +15mm | ||||

|

10,000mm |

0, +5mm+1mm/m | ||||

|

NOTE 1)The outside dimensions are measured across the flats at positions at least 50mm from the end of the HSS. |

|||||

Read more: BS EN 10210 for Hot Finished Structural Hollow Sections