LSAW Steel Pipe

- Seamless Steel Pipe

- ERW Steel Pipe

- SSAW Steel Pipe

- Well Casing & Tubing

- Drill Pipe

- Galvanized Steel Pipe

- Bending Pipe

-

LSAW Steel Pipe

LSAW Steel Pipe (Longitudinally Submerged Arc Welded Pipe) , DSAW Steel Pipe, SAWL Steel Pipe

Straight Seam Submerged Arc Welded Steel Pipe

UOE SAWL PIPES

Outside Diameter:Φ508mm- 1118mm (20"- 44")

Wall Thickness: 6.0-25.4mm 1/4"-1"

Quality Standards: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length: 9-12.3m (30'- 40')

Grades: API 5L A-X90,GB/T9711 L190-L625

JCOE SAWL PIPES

Outside Diameter:Φ406mm- 1626mm (16" - 64" )

Wall Thickness:6.0- 75mm (1/4" - 3" )

Quality Standards:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length:3-12.5m ( 10'- 41' )

Grades:API 5L A-X100, GB/T9711 L190-L690

Tolerance of Outside Diameter and Wall Thickness

Types

Standard

SY/T5040-2000

SY/T5037-2000

SY/T9711.1-1977

ASTM A252

AWWA C200-97

API 5L PSL1

Tube end OD deviation

±0.5%D

±0.5%D

-0.79mm~+2.38mm

<±0.1%T

<±0.1%T

±1.6mm

Wall thickness

±10.0%T

D<508mm, ±12.5%T

-8%T~+19.5%T

<-12.5%T

-8%T~+19.5%T

5.0mm

D>508mm, ±10.0%T

T≥15.0mm, ±1.5mm

Chemical Composition and Mechanical Properties of LSAW Steel Pipe

Standard

Grade

Chemical Composition(max)%

Mechanical Properties(min)

C

Mn

Si

S

P

Yield Strength

(Mpa)

Tensile Strength

(Mpa)

GB/T700-2006

A

0.22

1.4

0.35

0.050

0.045

235

370

B

0.2

1.4

0.35

0.045

0.045

235

370

C

0.17

1.4

0.35

0.040

0.040

235

370

D

0.17

1.4

0.35

0.035

0.035

235

370

GB/T1591-2009

A

0.2

1.7

0.5

0.035

0.035

345

470

B

0.2

1.7

0.5

0.030

0.030

345

470

C

0.2

1.7

0.5

0.030

0.030

345

470

BS En10025

S235JR

0.17

1.4

-

0.035

0.035

235

360

S275JR

0.21

1.5

-

0.035

0.035

275

410

S355JR

0.24

1.6

-

0.035

0.035

355

470

DIN 17100

ST37-2

0.2

-

-

0.050

0.050

225

340

ST44-2

0.21

-

-

0.050

0.050

265

410

ST52-3

0.2

1.6

0.55

0.040

0.040

345

490

JIS G3101

SS400

-

-

-

0.050

0.050

235

400

SS490

-

-

-

0.050

0.050

275

490

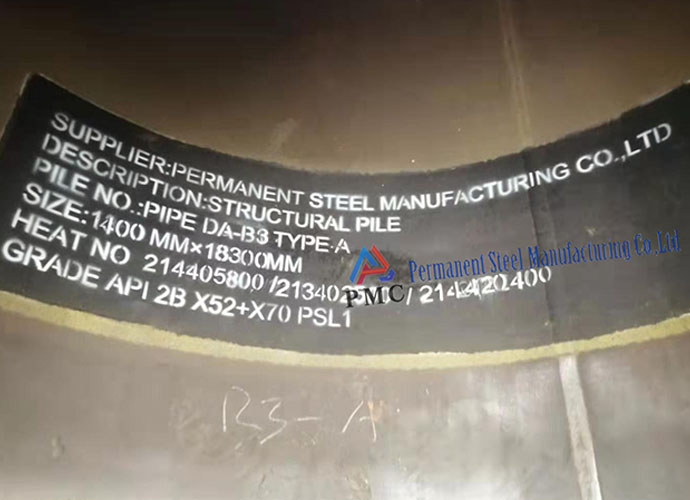

API 5L PSL1

A

0.22

0.9

-

0.03

0.03

210

335

B

0.26

1.2

-

0.03

0.03

245

415

X42

0.26

1.3

-

0.03

0.03

290

415

X46

0.26

1.4

-

0.03

0.03

320

435

X52

0.26

1.4

-

0.03

0.03

360

460

X56

0.26

1.1

-

0.03

0.03

390

490

X60

0.26

1.4

-

0.03

0.03

415

520

X65

0.26

1.45

-

0.03

0.03

450

535

X70

0.26

1.65

-

0.03

0.03

585

570

LSAW Steel Pipe Manufacturing Process:

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated as LSAW) is a professional expression term for LSAW steel pipe. It uses a single medium and thick plate as the raw material, and the steel plate is pressed (rolled) into a tube blank in a mold or a forming machine. The pipe is produced by submerged arc welding and expanded diameter.

UOE LSAW pipe forming process:

The three main forming processes of UOE LSAW steel pipe forming process include: steel plate pre-bending, U forming and O forming. Each process adopts a dedicated forming press to complete the three processes of pre-bending the edge of the steel plate, U forming and O forming in sequence to deform the steel plate into a circular tube.

JCOE LSAW pipe forming process:

Forming: After several steps of stamping on the JCO forming machine, first half of the steel plate is pressed into a "J" shape, then the other half of the steel plate is pressed into a "J" to form a "C" shape, and finally pressurized from the middle to form An open "O"-shaped tube blank is formed.

Tests of LSAW steel pipe

Chemical Component Analysis

Mechanical Properties – Elongation, Yield Strength, Ultimate Tensile Strength

Technical Properties – DWT Test, Impact Test, Blow Test, Flattening Test

X-ray Test

Exterior Size Inspection

Hydrostatic Test

UT Test

Transportation of LSAW steel pipe

When transporting, loading and unloading lsaw welded pipes, special hoisting and transportation tools should be used to avoid scratching the surface.

Production equipment of LSAW steel pipe

Plate edge milling machine

The milling machine mills the two sides of the plate to exacting standards in order to meet width, edging and groove shape specifications.

Edge crimping machine

The crimping machine crimps the edges of the plate to form the required curvature.

Tack welding machine

The two edges of the open seam pipe are brought together by the tack welding machine. then welded by the tack welder using a metal active - gas arc welding("MAG" )process.

Forming machine

Utilizes the "JCO" process to bend and form the crimped steel plate into a steel pipe.

Interior welding machine

The interior longitudinal seam of the pipe is welded from the inside by fixing 4 welding heads while moving pipe and using submerged-arc welding process.

End facing machine

The machine levels the pipe end with rotating cutter heads to ensure that required groove and edge specifications are met.

Hydrostatic tester

Using end face sealing technology eliminates blind zones during hydrostatic testing. The tester is also equipped with automatic recording and storing functions.

Expanding machine

The pipe is subjected to full-length expansion to increase the precision of the pipe dimensions and to improve the internal stress distribution.

Automated ultrasonic testing equipment

The superiority of phased arrayultra sonic technology:

(1 )Adopting electron control method for fast linear scanning or sector scanning without moving probe or moving less. thus greatlyim prove detection efficiency.

(2)Controlting the sound beam by setting detection angles, its good sound beam reachability can enhances reliability and accuracy of detection.

(3) Dynamic control the deflection and focus of sound beam realizes the detection of pipes with different wall thickness without replacing probes.