Drill Pipe

- Seamless Steel Pipe

- ERW Steel Pipe

- SSAW Steel Pipe

- LSAW Steel Pipe

- Well Casing & Tubing

- Galvanized Steel Pipe

- Bending Pipe

-

Drill Pipe

Standard: API 5D

Grades: E75, X95, G105, S135

Drill Pipe

2-3/8" to 7-5/8" OD, Range 2 and 3

Heavy Weight Drill Pipe

2-3/8" to 6-5/8" OD, Range 2 and 3

Application:

Drill pipe is for exploration and development of oil and gas wells.

Drill Collars

2-7/8" to 14"Length: 30Ft / 31Ft / 43Ft / Range1~Range3

Connection Type: NC, REG, FH, IF

Material: Stainless Steel / Alloy Steel /Carbon Steel / 4145H

Classification: Non Magnetic Drill Collar, Slick Drill Collar, Spiral Drill Collar, Square Drill Collars, Monel Drill Collar, Pony Drill Collar, Spesifikasi Drill CollarConnection threads: NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH.

Heavy weight drill pipe is a medium-weight drilling pipe, (referred standards in API SPEC 7-1). It has bigger wall thickness than common drilling pipe and smaller than drill collar.

Application:

Oil And Gas Well Drilling

Oilfield Drilling

Mine Blasting

Water Well Drilling

Geothermal Wells Drilling

Fore Poling

Coal And Nonferrous Metal Mining Projects

Types of Drill Pipe:

Drill pipe

Heavy weight drill pipe

Tool joint

Pup joint

Upset of drill pipe:

The upset (thread-end finish) refers to the wall of the tool joint at the threaded connection. Drill pipe is offered with an internal upset (IU), an external upset (EU), or an internal-external upset (IEU).

IU - In an internal upset increased thickness along the inside walls compensate for the metal removed in threading with a uniform, straight outside wall.

EU - In an external upset the increased thickness along the outside diameter of the tubing compensates for the metal removed in threading with a straight bore.

IEU - In an internal-external upset thickness is increased along both the inside and outside walls of the pipe to compensate for the metal removed in threading.

Drill pipe is a steel pipe with thread at the end, which is used to connect the surface equipment of the drilling rig to the drilling and grinding equipment or the bottom hole equipment at the bottom of the drilling. Drill pipe can be divided into three categories: kelly, drill pipe and heavy drill pipe.

Drill collar is located at the bottom of the drill string and is the main component of the lower drill tool assembly. Its main feature is that the wall thickness is larger, and it has greater gravity and rigidity. In order to facilitate tripping work, elevator grooves and slip grooves can be processed on the outer surface of the inner thread of the drill collar. Drill collars are generally divided into three types: spiral drill collars, non-magnetic drill collars, and integral drill collars.

Sizes & Weight of Drill Pipe:

Designations* Tool Joint Data Pipebody OD (Inches) Poundage (Pounds Per Foot) Grade Upset Type Rotary Shouldered Connection OD (Inches) PIN ID (Inches) Pin OD Length* (Inches) Box OD Length* (Inches) 2-3/8 6.65 E EU NC26 3-3/8 1-3/4 7 8 2-3/8 6.65 X,G EU NC26 3-3/8 1-3/4 7 8 2-3/8 10.40 E EU NC31 4-1/8 2-1/8 7 9 2-3/8 10.40 X,G EU NC31 4-1/8 2 7 9 2-3/8 10.40 S EU NC31 4-3/8 1-5/8 7 9 3-1/2 9.50 E EU NC38 4-3/4 2-11/16 8 10-1/2 3-1/2 13.30 E EU NC38 4-3/4 2-11/16 8 10-1/2 3-1/2 13.30 X EU NC38 5 2-9/16 8 10-1/2 3-1/2 13.30 G EU NC38 5 2-7/16 8 10-1/2 3-1/2 13.30 S EU NC38 5 2-1/8 8 10-1/2 3-1/2 15.50 E EU NC38 4-3/4 2-9/16 8 10-1/2 3-1/2 15.50 X EU NC38 5 2-7/16 8 10-1/2 3-1/2 15.50 G EU NC38 5 2-1/8 8 10-1/2 3-1/2 15.50 S EU NC40 5-1/2 2-1/4 7 10 4 14.00 E IU NC40 5-1/4 2-13/16 7 10 4 14.00 X IU NC40 5-1/4 2-13/16 7 10 4 14.00 G IU NC40 5-1/4 2-13/16 7 10 4 14.00 S IU NC40 5-1/4 2-9/16 7 10 4 14.00 E EU NC46 6 3-1/4 7 10 4 14.00 X,G EU NC46 6 3-1/4 7 10 4 14.00 S EU NC46 6 3 7 10 4-1/2 16.60 E EU NC50 6-5/8 3-3/4 7 10 4-1/2 16.60 X EU NC50 6-3/8 3-3/4 7 10 4-1/2 16.60 G EU NC50 6-5/8 3-3/4 7 10 4-1/2 16.60 S EU NC50 6-3/8 3-1/2 7 10 4-1/2 20.00 E EU NC50 6-3/8 3-3/4 7 10 4-1/2 20.00 X EU NC50 6-5/8 3-1/2 7 10 4-1/2 20.00 G EU NC50 6-3/8 3-1/2 7 10 4-1/2 20.00 S EU NC50 6-5/8 3-1/4 7 10 4-1/2 16.60 E IEU NC46 6-1/4 3-1/4 7 10 4-1/2 16.60 X IEU NC46 6-1/4 3-1/4 7 10 4-1/2 16.60 G IEU NC46 6-1/4 3 7 10 4-1/2 16.60 S IEU NC46 6-1/4 2-3/4 7 10 4-1/2 20.00 E IEU NC46 6-1/4 3-1/4 7 10 4-1/2 20.00 X IEU NC46 6-1/4 3 7 10 4-1/2 20.00 G IEU NC46 6-1/4 2-3/4 7 10 4-1/2 20.00 S IEU NC46 6-3/8 2-1/2 7 10 5 19.50 E IEU NC50 6-5/8 3-3/4 7 10 5 19.50 X IEU NC50 6-5/8 3-1/2 7 10 5 19.50 G IEU NC50 6-5/8 3-1/4 7 10 5 19.50 S IEU NC50 6-5/8 2-3/4 7 10 5 19.50 E IEU 5-1/2FH 7 3-3/4 8 10 5 19.50 X,G IEU 5-1/2 FH 7 3-3/4 8 10 5 19.50 S IEU 5-1/2 FH 7-1/4 3-1/2 8 10 5 25.60 E NC50 6-5/8 3-1/2 3-3/4 7 10 5 25.60 X IEU NC50 6-5/8 3 7 10 5 25.60 G IEU NC50 6-5/8 2-3/4 7 10 5 25.60 E IEU 5-1/2 FH 7 3-1/2 8 10 5 25.60 X IEU 5-1/2 FH 7 3-1/2 8 10 5 25.60 G IEU 5-1/2 FH 7-1/4 3-1/2 8 10 5 25.60 S IEU 5-1/2 FH 7-1/4 3-1/4 8 10 5-1/2 21.90 E IEU 5-1/2 FH 7 4 8 10 5 21.90 X IEU 5-1/2 FH 7 3-3/4 8 10 5-1/2 21.90 G IEU 5-1/2 FH 7-1/4 3-1/2 8 10 5 21.90 S IEU 5-1/2 FH 7-1/2 3 8 10 5-1/2 24.70 E IEU 5-1/2 FH 7 4 8 10 5 24.70 X,G IEU 5-1/2 FH 7-1/4 3-1/2 8 10 5-1/2 24.70 S IEU 5-1/2 FH 7-1/2 3 8 10 6-5/8 25.20 E IEU 6-5/8 FH 8 5 8 11 6-5/8 25.20 X IEU 6-5/8 FH 8 5 8 11 6-5/8 25.20 G IEU 6-5/8 FH 8-1/4 4-3/4 8 11 6-5/8 25.20 S IEU 6-5/8 FH 8-1/2 4-1/4 8 11 6-5/8 27.70 E IEU 6-5/8 FH 8 5 8 11 6-5/8 27.70 X,G IEU 6-5/8 FH 8-1/4 4-3/4 8 11 6-5/8 27.70 S IEU 6-5/8 FH 8-1/2 4-1/4 8 11

Chemical composition

Grade

Chemical Composition

P S E-75

≤0.020

≥689

X-95

≤0.020

≥724

G-105

≤0.020

≥793

S-135

≤0.020

≥1000

Mechanical Properties API Steel Drill Pipe

Grade

E-75

X-95

G-105

S-135

Yield Strength (minimum psi)

75,000

95,000

105,000

135,000

Yield Strength (maximum psi)

105,000

125,000

135,000

165,000

Tensile Strength (minimum psi)

100,000

105,000

115,000

145,000

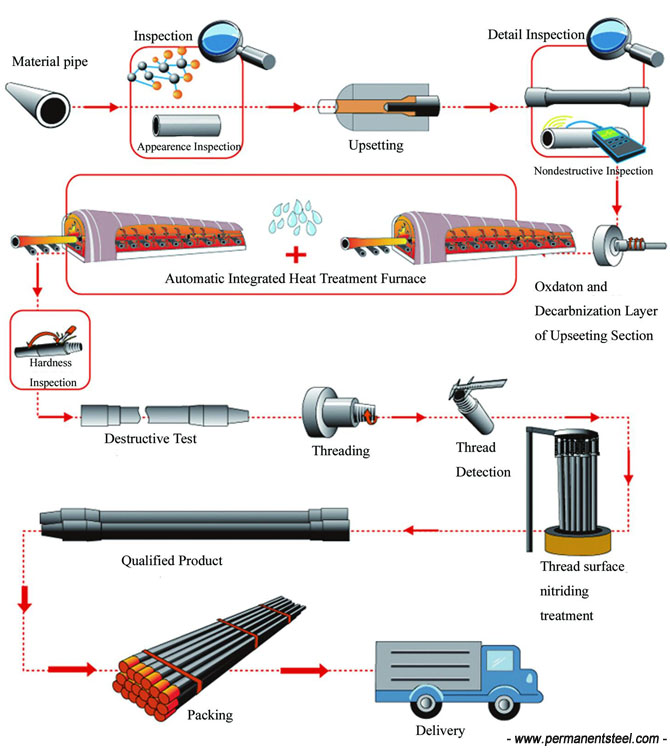

Drill Pipe Production Process Flow Chart: