Well Casing & Tubing

- Seamless Steel Pipe

- ERW Steel Pipe

- SSAW Steel Pipe

- LSAW Steel Pipe

- Drill Pipe

- Galvanized Steel Pipe

- Bending Pipe

-

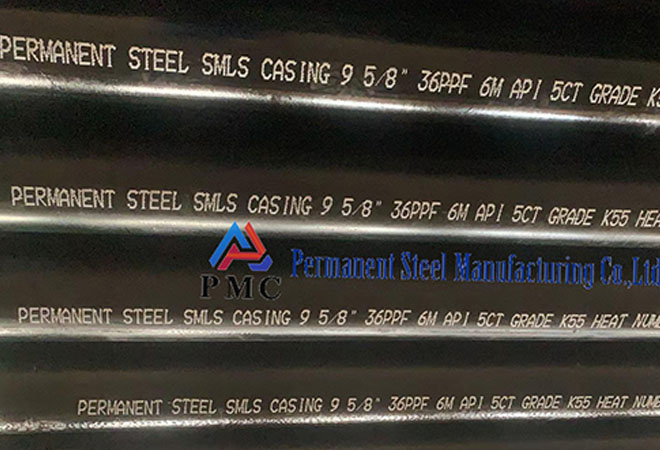

Well Casing & Tubing

Casing Pipe, Steel Casing Pipe, Well Casing, OCTG Casing

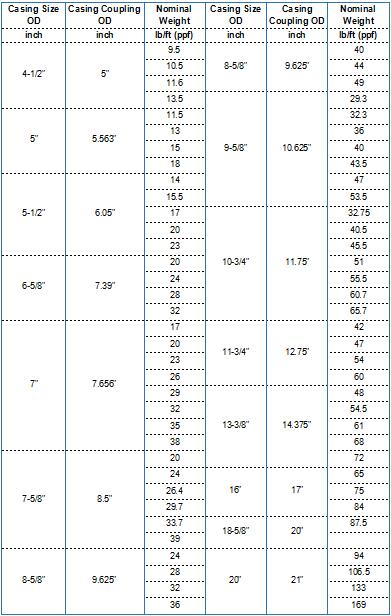

Sizes:

Out Diameter: 1.315"- 20"

Wall Thickness: 0.133"-0.500"

Length:R1(group1),R2(group2),R3(group3)

Materials & Grades:

Casing: API 5CT J55, K55, N80, L80-1, L80-9Cr, L80-13Cr, P110

Application:

oil well extracting

borehole

borewell

Types:

Connections:

P (Plain end)

STC (short threads)

LTC (long threads)

BTC (buttress threads)

Premium gas-tight connectors

Non-upset ends (NUE)

External upset ends (EUE)

Premium gas-tight connectors

Others special connectors

Chemical compositions of casing pipe

Standard Grade Chemical compositions(%)

API SPEC 5CT

J55

C Si Mn P S Cr Ni Cu Mo V K55 0.34~0.39

0.20~0.35

1.25~1.50

≤0.020

≤0.015

≤0.15

≤0.20

≤0.20

/ / N80

0.34~0.38

0.20~0.35

1.45~1.70

≤0.020

≤0.015

≤0.15

/ / / 0.11~0.16

L80

0.15~0.22

≤1.00

0.25~1.00

≤0.020

≤0.010

12.0~14.0

≤0.20

≤0.20

/ / P110

0.26~0.395

0.17~0.37

0.40~0.70

≤0.020

≤0.010

0.80~1.10

≤0.20

≤0.20

0.15~0.25

≤0.08

Mechanical properties of casing pipe

Grade Type Total elongation

under load

(%)

Yield strength

(min)Mpa

Yield strength

(max)Mpa

Tensile strength

min Mpa

Hardness

Max (HRC)

Hardness

Max (HBW)

J55 - 0.5

379 552 517 - - K55 - 0.5

379 552 655 - - N80 1 0.5

552 758 689 - - N80 Q 0.5

552 758 689 - - L80 1 0.5

552 655 655 23 241 L80

9Cr 0.5

552 655 655 23 241 L80

13Cr 0.5

552 655 655 23 241 C90 - 0.5

621 724 689 25.4 255 C95 - 0.5

655 758 724 - - T95 - 0.5 655 758 724 25.4 255 P110 - 0.6 758 965 862 - - Q125 All 0.65 862 1034 931 - -

Casing Pipe Manufacturing Process:

Steel ingot heating → hydraulic punching → reheating → extension → periodic rolling → reheating → sizing → cooling → straightening → pipe cutting → inspection

1. An annular heating furnace is required for ingot heating;

2. Punching and reheating with hydraulic press;

3. The oil casing plant uses a two-roller guide plate extension machine for extension;

4. Re-use a disc heating furnace for periodic rolling, and use a non-entry furnace for reheating, cooling, straightening, pipe cutting, and inspection.

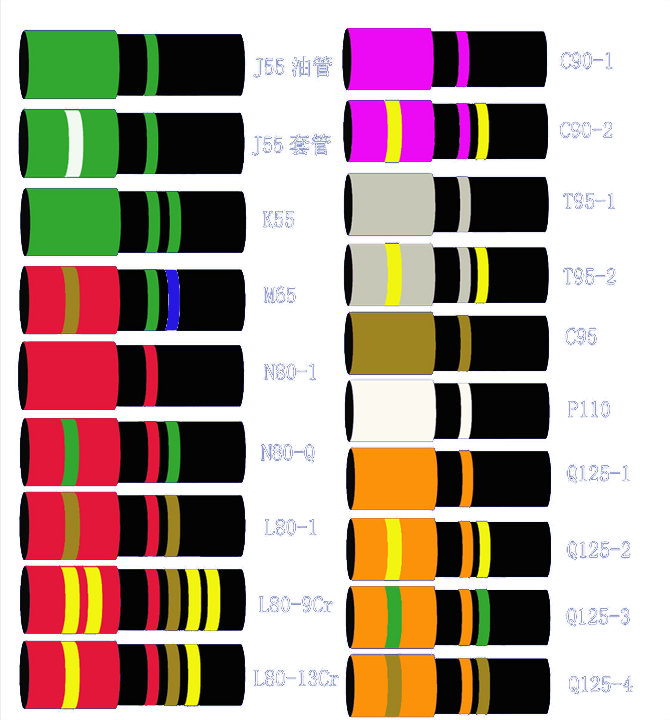

Color Codes for API 5CT Casing and Tubing: