Painting Workflow

1.Ensure all tests are performed on piping system before starting painting work.

2.Clean painting surface to remove oils, grease, dirt.

3.Ensure proper room temperature and humidity levels.

4.Use hand tools, machine tools, shot blasters etc to clean surface as per relevant standards and project requirements.

5.Apply primer within 4 hours of surface preparation.

6.Apply paint coats after previous coats have dried up, as per instructions of paint manufacturer.

Components Requiring Painting

a.Un-insulated carbon steel pipes, fittings, valves, special items etc. require painting.

b.Carbon steel ducts, furnaces and stacks require painting.

c.All un-insulated equipments like columns, vessels, drums, heat exchangers, pumps, compressors, electrical panels, motors etc. require painting.

d.All structural componets like steel members, platforms, ladders,handrails etc. required painting.

Note:Stainless steel piping is not painted. Identification marking may be done on this piping.

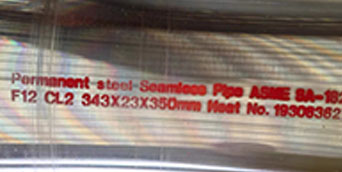

Marking on steel pipe

1.Manufacturer name or his registered trademark;

1.Manufacturer name or his registered trademark;

2.Standard of steel products;

3.The grade of the material;

4.The heat number;

5.Pipe number;

6.Wall thickness;

7.Actual length;

8.Out diameter;

Package of steel pipe

Packaging methods for steel pipe would vary depending on the type and size of the pipes.In this article ,SHEW-E STEEL will provide the packaging methods applied for the most common types of piping,but additional packaging precautions should be taken in some cases to prevent damages mainly caused by the wiggling and bending during the sealift handing and transportation stages and process.

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles.

The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements.

When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3.

When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below.

Wooden box package

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube.

When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg.

When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg.