How to Extend the Service Life of Elbow Fittings?

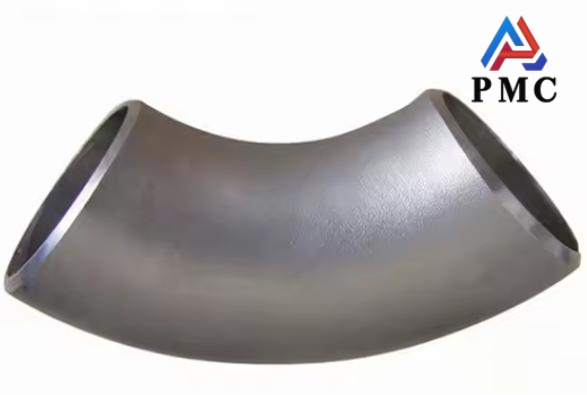

Elbow fittings are key piping components used to change the direction of flow, typically at 45° or 90° angles. Available in seamless or welded types, they can be threaded or socket-welded, with long or short radius options to meet specific system needs. Elbow fittings ensure safe, efficient, and reliable pipeline direction changes.

Common materials of elbow fittings

Elbow fittings are made from various materials to meet different industrial needs. The most common types include:

1. Stainless steel elbows

Highly resistant to corrosion and heat, stainless elbows (e.g., SS304, SS316) are ideal for chemical, food-grade, and marine applications.

2. Carbon Steel Elbows

Strong and economical, carbon elbows (e.g., ASTM A234 WPB) are widely used in high-pressure systems like oil, gas, and water pipelines. Protective coatings can improve their corrosion resistance.

3. Alloy Steel Elbows

Enhanced with elements like chromium or molybdenum, alloy steel elbows perform well under high temperatures and pressures.

4. Copper Elbows

Common in plumbing and HVAC, copper elbows offer good thermal conductivity and corrosion resistance.

5. PVC/CPVC Elbows

Lightweight and rust-free, these plastic elbows are used in residential, irrigation, and chemical drainage systems.

How to extend the service life of elbow fittings?

1. Material selection

Select high-quality materials: Choose high-quality materials that are corrosion-resistant, wear-resistant, and high-temperature resistant to make elbow pipe fittings, such as stainless steel, alloy steel, etc. These materials have better corrosion resistance and mechanical properties, and can remain stable in harsh environments, thereby extending the service life of elbow pipe fittings. Select materials according to the environment: Select appropriate materials according to the use environment of the elbow fittings. For example, in a humid or corrosive environment, materials with better corrosion resistance should be selected; in a high temperature environment, materials that can withstand high temperatures should be selected.

2. Installation process

Clean the pipes thoroughly: Before installation, clean the pipes thoroughly to remove impurities and dirt to avoid damage to elbow fittings during installation. Follow the correct installation method: The correct installation method and steps should be followed during installation to ensure that the elbow fittings are tightly and firmly connected to the pipeline to avoid leakage or looseness. At the same time, the installation stress should be controlled to avoid excessive stress causing deformation or rupture of elbow fittings. Use of special tools: During the installation process, special tools and equipment should be used to ensure the quality and efficiency of the installation.

3. Usage Environment

Avoid harsh environments: Avoid elbows and fittings from being exposed to harsh environments such as high temperature, high pressure, and corrosive media. If it cannot be avoided, appropriate protective measures should be taken, such as adding insulation layers, anti-corrosion coatings, etc.

Check the environment regularly: Check the use environment of elbow fittings regularly to promptly identify and deal with factors that may affect their service life, such as temperature changes, humidity changes, chemical corrosion, etc.

4. Maintenance

Regular inspection: Regularly inspect elbow fittings, including appearance inspection, sealing inspection, etc., to promptly discover and deal with potential problems. For problems found, such as corrosion, wear, cracks, etc., they should be repaired or replaced in time.

Cleaning and maintenance: Regularly clean the impurities and dirt inside the elbow fittings to keep them clean. At the same time, perform necessary lubrication and maintenance on the elbow fittings to reduce wear and friction.

Anti-corrosion treatment: For elbow fittings exposed to corrosive environments, anti-corrosion treatment should be carried out regularly, such as applying anti-corrosion paint, electrochemical protection, etc.

5. Using advanced technology

Real-time monitoring: Use sensors and monitoring systems to monitor elbow fittings in real time, detect abnormal conditions in time and take measures. This helps prevent potential problems and thus extend the service life of elbow fittings. Advanced anti-corrosion technology: Use advanced anti-corrosion technologies, such as electrochemical protection, coating protection, etc. to improve the corrosion resistance of elbow fittings. These technologies can extend the service life of elbow fittings in corrosive environments.

Read more: Quality Inspection Method for Elbow Fittings