Rectangular Tube

- Rectangular SS Tube

- ERW Rectangular Tube

- Galvanised Square Tube

- Stainless Square Tube

- ERW Square Steel Tube

- Square Tube

-

Rectangular Tube

Standard:

ASTM A500 Grade B,

ASTM A513 (1020-1026)

ASTM A36 (A36)

EN 10210:S235,S355,S235JRH,

S355J2H,S355NH

EN 10219:S235,S355,S235JRH,S275J0H, S275J2H, S355J0H, S355J2H

Surface conditions:

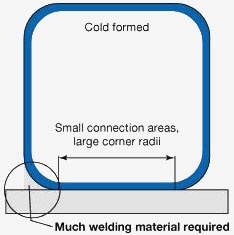

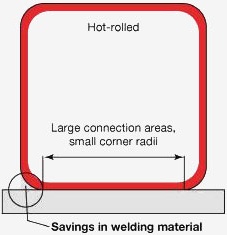

Hot rolled

Cold rolled

MS Rectangular tube sizes (It can be customized according to customer requirements)

Size by Inch (diameter) Thickness

Sizes by MM (diameter)

Thickness

inch

inch

mm mm 1“ x 1/2"

0.065"

10mm×15mm

0.6mm~1.5mm

1“ x 3/4"

0.065"

10mm×20mm

0.6mm~1.5mm

0.095" 14mm×21mm

0.6mm~1.5mm

1 1/4" x 3/4"

0.065"

15mm×30mm

0.6mm~1.5mm

1 1/2" x 3/4"

0.065"

15mm×38mm

0.6mm~1.5mm

0.120" 20mm×20mm

0.6mm~2mm

1 1/2" x 1"

0.065"

20mm×30mm

0.6mm~2mm

0.072"

20mm×40mm

0.6mm~2mm

0.083"

20mm×50mm

0.6mm~2mm

0.120"

22mm×35mm

0.6mm~2mm

2“ x 1”

0.065"

25mm×40mm

0.9mm~2mm

0.083"

25mm×65mm

0.9mm~3.75mm

0.120"

30mm×20mm

1mm~2mm

0.188"

30mm×40mm

1mm~3.75mm

2” x 1 1/4“

0.065"

30mm×45mm

1mm~3.75mm

0.083"

30mm×50mm

1mm~3.75mm

2“ x 1 1/2”

0.083"

30mm×60mm

1mm~4mm

0.120"

40mm×25mm

1mm~4.5mm

2 1/2“ x 1 1/2”

0.072"

40mm×50mm

1mm~4.5mm

0.083"

40mm×60mm

1mm~4.5mm

0.120"

40mm×80mm

1mm~5mm

0.148"

40mm×100mm

1mm~5mm

0.188"

50mm×25mm

2mm~5mm

0.250"

50mm×30mm

2mm~5mm

3" x 1" 0.083"

50mm×60mm

2mm~5mm

0.120"

50mm×80mm

2mm~5mm

0.188"

50mm×100mm

2mm~5mm

3“ x 1 1/2”

0.083"

60mm×30mm

2mm~6mm

0.120"

60mm×40mm

2mm~6mm

0.188"

60mm×80mm

2mm~6mm

0.250" 70mm×50mm

2mm~6mm

3“ x 2”

0.065

80mm×30mm

2mm~8mm

0.083

80mm×40mm

2mm~8mm

0.125

80mm×60mm

2mm~8mm

0.188

80mm×100mm

2mm~8mm

0.250

100mm×50mm

2mm~8mm

3“ x 2”

0.083"

120mm×60mm

2.5mm~10mm

0.120"

120mm×80mm

2.5mm~10mm

0.188"

140mm×60mm

2.5mm~10mm

0.250"

140mm×80mm

2.5mm~10mm

0.312" 150mm×100mm

2.5mm~12mm

4“ x 1 1/2”

0.120"

160mm×80mm

2.5mm~12mm

0.188"

180mm×150mm

2.5mm~12mm

4“ x 2”

0.083"

200mm×100mm

4mm~12mm

0.120"

200mm×150mm

4mm~12mm

0.188"

220mm×140mm

4mm~12mm

0.250"

250mm×150mm

6mm~12mm

0.312"

250mm×100mm

6mm~12mm

0.375"

250mm×200mm

6mm~30mm

4“ x 2 1/2”

0.188"

300mm×100mm

6mm~30mm

0.250"

300mm×150mm

6mm~30mm

4" x 3" 0.083"

300mm×200mm

6mm~30mm

0.120"

300mm×250mm

6mm~30mm

0.188"

400mm×250mm

8mm~30mm

0.250"

400mm×300mm

8mm~30mm

0.312"

450mm×200mm

8mm~30mm

0.375"

450mm×250mm

8mm~30mm

4 1/2“ x 2 1/2”

0.188"

400mm×300mm

8mm~30mm

0.250"

400mm×350mm

8mm~30mm

5" x 2” 0.120"

500mm×200mm

10mm~30mm

0.188"

500mm×250mm

10mm~30mm

0.250"

500mm×300mm

10mm~30mm

0.312"

500mm×350mm

10mm~30mm

0.375"

500mm×400mm

10mm~30mm

5" x 2 1/2”

0.120"

500mm×450mm

10mm~30mm

0.188"

600mm×200mm

10mm~28mm

0.250"

600mm×400mm

10mm~28mm

5" x 3"

0.188"

600mm×500mm

10mm~28mm

0.250"

800mm×400mm

10mm~28mm

0.312"

800mm×600mm

10mm~28mm

0.375"

800mm×700mm

10mm~28mm

0.500"

1000mm×400mm

10mm~28mm

5" x 4"

0.188"

1000mm×500mm

10mm~28mm

0.250"

1000mm×600mm

10mm~28mm

0.312"

1000mm×800mm

10mm~28mm

0.375"

6" x 2"

0.120"

0.188"

0.250"

0.312"

0.375"

6“ x 3"

0.120"

0.188"

0.250"

0.312"

0.375"

0.500"

6“ x 4"

0.120"

0.188"

0.250"

0.312"

0.375"

0.500"

7“ x 3"

0.188"

0.250"

0.312"

0.375"

7“ x 4”

0.188"

0.250"

0.312"

0.375"

0.500"

7“ x 5” 0.188"

0.250"

0.312"

0.375"

0.500"

8“ x 2”

0.188"

0.250"

0.312"

0.375"

8“ x 3”

0.188"

0.250"

0.312"

0.375"

0.500"

8“ x 4”

0.188"

0.250"

0.312"

0.375"

0.500"

8" x 6”

0.188"

0.250"

0.312"

0.375"

0.500"

0.625"

9“ x 3”

0.188"

0.250"

0.312"

0.375"

9“ x 7”

0.188"

0.250"

0.312"

0.375"

0.500"

0.625"

10“ x 2”

0.188"

0.250"

0.312"

0.375"

10" x 3”

0.188"

0.250"

0.312"

0.375"

10" x 4"

0.188"

0.250"

0.312"

0.375"

0.500"

10" x 5"

0.188"

0.250"

0.312"

0.375"

0.500"

10" x 6"

0.188"

0.250"

0.312"

0.375"

0.500"

0.625"

10" x 8"

0.188"

0.250"

0.375"

0.500"

0.625"

12" x 2" 0.188"

0.250"

0.312"

0.375"

12" x 3"

0.188"

0.250"

0.312"

0.375"

12" x 4"

0.188"

0.250"

0.312"

0.375"

0.500"

0.625"

12" x 6"

0.188"

0.250"

0.312"

0.375"

0.500"

0.625"

12" x 8"

0.250"

0.312"

0.375"

0.500"

0.625"

12" x 10"

0.250"

14" x 4"

0.250"

0.312"

0.375"

0.500"

14" x 6"

0.250"

0.312"

0.375"

0.500"

14" x 10"

0.250"

0.312"

0.375"

0.500"

0.625"

16"x 4"

0.312"

0.375"

0.500"

16" x 8"

0.250"

0.312"

0.375"

0.500"

16" x 12"

0.312"

0.375"

0.500"

0.625" 18" x 6" 0.312"

0.375"

0.500"

20" x 4"

0.312"

0.375"

0.500"

20" x 8"

0.312"

0.375"

0.500"

20" x 12"

0.312"

0.375"

0.500"

0.625"

Chemical composition of material

Grade element

C Mn P S ASTM A500 Gr.b % 0.05%-0.23% 0.3%-0.6% 0.04% 0.04%

Acc.to EN10027/1 Acc.to EN10027/2 C% max (Norminal W.T.(mm) Si% max Mn% max P% max S% max N% max and IC 10

≤ 40

S235JRH 1.0039 0.17 0.20 - 1.40 0.045 0.045 0.009 S275JOH 1.0149 0.20 0.22 - 1.50 0.040 0.040 0.009 S275J2H 1.0138 0.20 0.22 - 1.50 0.035 0.035 - S355JOH 1.0547 0.22 0.22 0.55 1.60 0.040 0.040 0.009 S355J2H 1.0576 0.22 0.22 0.55 1.60 0.035 0.035 -

Mechanical properties of material

Grade Yield Strength

Tensile Strength

Elongation

A500.Gr.b

46 ksi 58 ksi 23% A513.GR.B 72 ksi 87 ksi 10%

Norm Yield Strength Tensile Strength Min.elogation Min.percent properties Acc.to EN10027/1

and IC 10

Acc.to EN10027/2 Norminal W.T.mm Norminal W.T.mm Longit. Cross Test temperature°C Average min.impact value ≤16

>6

>40

<3

≤3≤65

Norminal W.T.mm

≤65

≤65

≤40

>40

>40

≤65

≤65

≤40

S253JRH 1.0039 235 225 215 360-510 340-470 26 25 24 23 20 27 S275JOH 1.0149 275 265 255 410-580 410-560 22 21 20 19 0 27 S275J2H 1.0138 275 265 255 430-560 410-560 22 21 20 19 -20 27 S355JOH

1.0547 355 345 335 510-680 490-630 22 21 20 19 0 27 S355J2H 1.0576 355 345 335 510-680 490-630 22 21 20 19 -20 27

Equivalent specfications

EN 10210-1

NF A 49501 NF A 35501

DIN 17100 DIN 17123/4/5

BS 4360

UNI 7806

S235JRH E 24-2 St 37.2 – Fe 360 B S275JOH E 28-3 St 44.3 U 43 C Fe 430 C S275J2H E 28-4 St 44.3 N 43 D Fe 430 D S355JOH E 36-3 St 52.3 U 50 C Fe 510 C S355J2H E 36-4 St 52.3 N 50 D Fe 510 D S275NH – St E 285 N – – S275NLH – TSt E 285 N 43 EE – S355NH E 355 R St E 355 N – – S355NLH – TSt E 355 N 50 EE – S460NH E 460 R St E 460 N – – S460NLH – TSt E 460 N 55 EE – – block letter "S" means "STEEL FOR STRUCTURAL APPLICATIONS"

– the next fi gure means the minim. yield value required for wall thickness ≤16 mm

– "J2" means impact test value -20° C min. 27 joule

– block letter "H" means "HOLLOW SECTION".