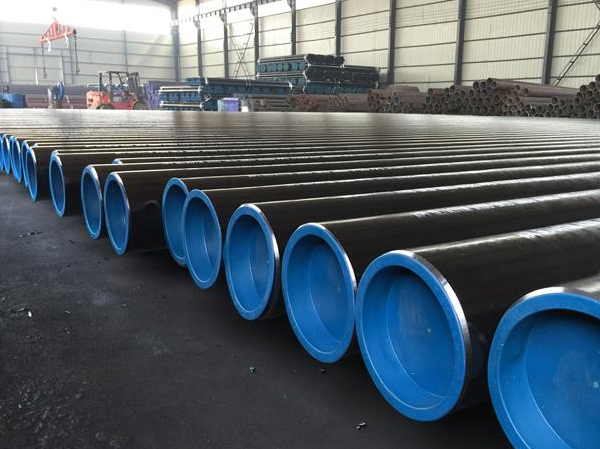

Best Practices for Seamless Steel Pipes in the Oil and Gas Industry

Seamless steel pipe production process:

The production process of seamless steel pipe mainly includes two methods: cold drawing and hot rolling. The cold drawing process is usually suitable for producing seamless steel pipes with small diameters and thin wall thicknesses, and has the advantages of high dimensional accuracy and good surface finish. The hot rolling process is suitable for producing seamless steel pipes with large diameters and thick walls, which can meet requirements such as high strength and pressure resistance. According to the specific usage scenarios and requirements, it is very important to choose the appropriate production process.

Material selection and quality control of seamless steel pipes:

In the oil and gas industry, material selection and quality control of seamless steel pipes are crucial. First of all, materials with good corrosion resistance, high strength and toughness should be selected, such as carbon steel, alloy steel, etc. Secondly, strict quality control must be carried out, including chemical composition analysis, mechanical performance testing, ultrasonic flaw detection, etc., to ensure that the quality of seamless steel pipes meets standard requirements.

The specific performance of seamless steel pipes in the oil and gas field:

1) Application of seamless steel pipes in oil wells

The applications of seamless steel pipes in oil wells mainly include oil pipes, casing pipes and drill pipes. Oil pipes are used to transport crude oil and natural gas and are required to have good corrosion resistance and high pressure resistance. Casing is used to fix the wall of the oil well and prevent the collapse of the oil well, and is required to have a certain degree of strength and corrosion resistance. Drill pipe is used in drilling operations and requires high strength and good wear resistance. The application of seamless steel pipes in oil wells must meet different working conditions and environmental requirements.

2) Application of seamless steel pipes in pipeline transportation

Seamless steel pipes are widely used in pipeline transportation systems in the oil and gas industry. Pipeline transportation requires seamless steel pipes to have good sealing, pressure resistance and corrosion resistance. At the same time, it is also necessary to consider the impact of factors such as temperature changes and pressure fluctuations on seamless steel pipes during pipeline transportation. Therefore, when designing and installing pipeline transportation systems, it is necessary to select appropriate seamless steel pipes according to specific conditions and take appropriate anti-corrosion measures to ensure the safe operation of the pipelines.

3) Application of seamless steel pipes in storage equipment

Seamless steel pipes play an important role in oil and gas storage equipment. Storage equipment requires seamless steel pipes to have good corrosion resistance, sealing and pressure resistance. Common storage equipment includes oil tanks, gas tanks, and gas storage warehouses. The application of seamless steel pipes in storage equipment requires consideration of factors such as the characteristics of the medium, storage pressure and temperature, selection of appropriate seamless steel pipes, and appropriate anti-corrosion treatment to ensure the safety and reliability of storage equipment.

Conclusion:

Seamless steel pipes have broad application prospects in the oil and gas industry. Best practices for seamless steel pipes in the oil and gas industry can be achieved by selecting appropriate production processes, strict material selection and quality control, as well as use and maintenance for different application scenarios. Only by continuously improving technical levels and quality standards can the demand for seamless steel pipes in the oil and gas industry be met.

Tips: ASTM A106 seamless pressure pipe (also known as ASME SA106 pipe) is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers, and ships where the piping must transport fluids and gases that exhibit higher temperatures and pressure levels.