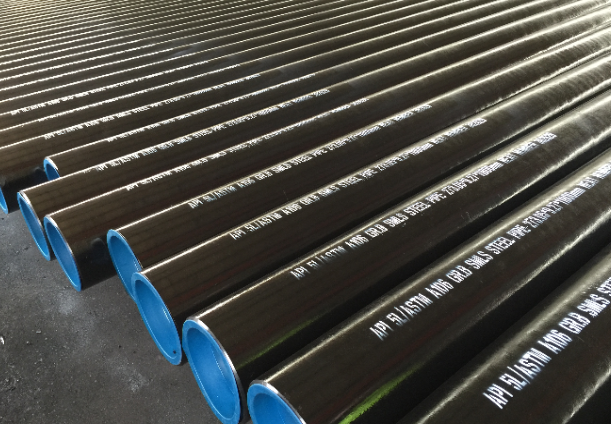

ASTM A106 Seamless Carbon Steel Pipe

ASTM A106 - Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

ASTM A106 Seamless steel pipe (also known as ASME SA106 pipes) is an American standard steel pipe.

This specification covers carbon steel pipe for high-temperature service. These pipes are suitable for welding, bending, flanging, and similar forming operations. Mechanical testing of the specimens shall include tensile, bending, flattening, hydrostatic and nondestructive electric tests. Specimens undergoing bending tests shall consist of sections cut from a pipe. For flattening tests, the specimens shall be smooth on the ends and burr-free, except when made on crop ends. All tests shall be performed in room temperature. If any test specimen shows flaws it can be discarded and substituted for another test specimen. Before testing, if a specimen has scribe scratches, a retest shall be allowed. A retest shall also be allowed if a specimen breaks in an inside or outside surface flaw.

For ASTM A106 seamless steel pipe could transport fluids or gasses at high temperature and pressure levels, with 3 grades A, B, C, most common used ASTM A106 Grade B is widely used in the projects of oil and gas refineries, power plants, petrochemical plants, boilers.

About ASTM A106 Grade B:

ASTM A106 Grade B Pipe (also known as ASME SA106 GR.B pipes) is used in power plants, boilers, petrochemical plants, oil and gas refineries, and ships where the piping must transport hot or cold liquids and gases under high pressures and temperatures. A106 GR. B Carbon Steel Seamless Pipes, A106 Gr B Sch 40 pipe, ASTM A106 Grade B Pipe Suppliers is available in various weights, sizes, and black and galvanized grades both seamless and electric welded. ASTM A106 Grade B Pipe sizes, less than 2" is it normally delivered as a cold drawn product. 2" and up are usually hot finished.

About ASTM A106 Grade C:

ASTM A106 Grade C Pipe (also known as ASME SA106 GR.C pipes) is a carbon-manganese steel pipe for high-temperature large-diameter boilers and superheaters. Its chemical composition is simple and similar to 20G carbon steel, but its carbon and manganese content is higher, so its yield strength is about 12% higher than that of 20G, and its plasticity and toughness are not bad. The steel has a simple production process and good cold and hot workability. Using it to replace 20G headers (economizer, water wall, low-temperature superheater and reheater header) can reduce the wall thickness by about 10%, which can save material costs, reduce welding workload, and improve headers The stress difference at start-up.

Mechanical properties:

|

Standard |

Steel Grade |

Tensile strength (MPA) |

Yield strength (MPA) |

|

ASTM A106 |

A |

≥330 |

≥205 |

| B |

≥415 |

≥240 |

|

| C |

≥485 |

≥275 |

Chemical composition:

|

Standard |

Steel Grade |

C |

Si |

Mn |

P | S | Cr | Mo | Cu | Ni | V |

|

ASTM A106 |

A |

≤0.25 |

≥0.10 |

0.27~0.93 |

≤0.035 |

≤0.035 |

≤0.40 |

≤0.15 |

≤0.40 |

≤0.40 |

≤0.08 |

| B |

≤0.30 |

≥0.10 |

0.29~1.06 |

≤0.035 |

≤0.035 |

≤0.40 |

≤0.15 |

≤0.40 |

≤0.40 |

≤0.08 |

|

| C |

≤0.35 |

≥0.10 |

0.29~1.06 |

≤0.035 |

≤0.035 |

≤0.40 |

≤0.15 |

≤0.40 |

≤0.40 |

≤0.08 |

1. Below the specified maximum carbon content, each time the carbon content decreases by 0.01%, the A106 seamless steel pipe is allowed to increase the manganese content by 0.06% above the specified maximum manganese content, but the maximum shall not exceed 1.35%;

2. The sum of the five elements Cu, Ni, Cr, Mo and V shall not be greater than 1.00%.

FAQ:

Q: What is the difference between pipe design material A106 and SA106?

A: There is no difference between pipe design material A106 and SA106,

Because the 2013 edition of the ASME II material chapter has pointed out that SA106 is consistent with ASTM A106,In addition, SA106 is a grade of American ASME,And A106 is the grade of ASTM.

Q: What does the mark CD in the steel pipe SA106Gr.B standard mean?

A: CD means cold drawn,SA106 stipulates that pipes below DN40 can be hot-rolled or cold-drawn; pipes above DN50 are conventionally hot-rolled. When the manufacturer and the purchaser reach an agreement, cold-drawn manufacturing is allowed.

Q: What is the difference between ASME SA-106 and ASME SA-106M?

A: The difference between ASME SA-106 and ASME SA-106M is that if the size standard is imperial, use ASME SA-106, if the size standard is metric, use ASME SA-106M.

Tips: The A106 includes A106-A, A106-B and A106-C. A106 A is equivalent to the China's 10# material, and the A106 B is equivalent to the China's 20# material. It belongs to the ordinary carbon steel series and is one of the commonly used materials. ASTM A106 seamless steel pipe includes two processes of cold drawing and hot rolling. In addition to the different production processes, the two are different in accuracy, surface quality, minimum size, mechanical properties, and organizational structure. Widely used in petroleum, chemical, boiler, power station, shipbuilding, machinery manufacturing, automobile, aviation, aerospace, energy, geology, construction and military industries.

Go here if you are looking for the "ASTM A53 Steel Pipe Specifications".

- 【Prev】 : ASTM A53 Steel Pipe

- 【Next】 : Anticorrosive Spiral Steel Pipe(SSAW)