Introduction to Casing and Tubing for Oil Well Construction

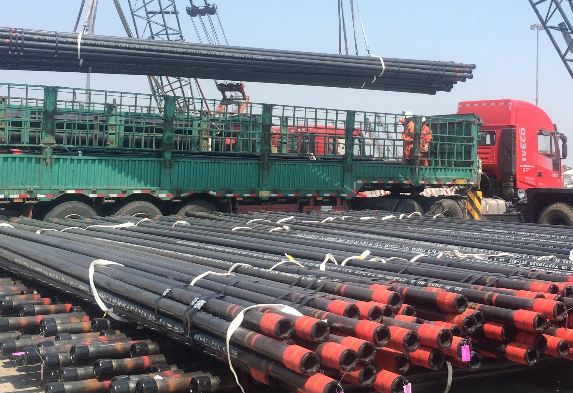

Oil casing pipe is a series of steel pipes inserted into a drilled oil well to stabilize the well, prevent contaminants and water from entering the oil flow, and prevent oil from seeping into the groundwater. The casing is installed in layers of sections of decreasing diameter that are joined together to form the casing string. There are five types of casing strings: conductor casing, surface casing, intermediate casing, casing liner and production casing.

Casing is typically made from carbon steel, but as the primary structural component of an oil well, the grade of steel used to make the casing and the specifications of the finished material are very important.

Most countries follow American Petroleum Institute (API) standards for the design, manufacture, testing, and transportation of oil and gas casing for use in hydraulically fractured wells. According to API's Hydraulic Fracturing Operations—Well Construction and Integrity Guidelines, casing must meet stringent requirements for compression, tensile, collapse and burst resistance, quality, and consistency. Well casing should withstand hydraulic fracturing pressures, production pressures and corrosive conditions. Used or refurbished casing should meet the same API performance requirements as new casing.

Once the casing is in place, pipes enter the casing to transport the oil or natural gas. Casing and tubing are manufactured to certain diameters and wall thicknesses. The Society of Petroleum Engineers' PetroWIKI website describes the tubing manufacturing process:

API specifies seamless or electric welding processes for pipe manufacturing. Seamless pipe is defined as a forged steel pipe product without welds. It is manufactured from hot-worked steel or, if required, by subsequent cold finishing of the hot-worked product to produce the desired shape, size and properties. Due to the nature of manufacturing, the cross-section of the tube wall area may be slightly off-center and the tube will be slightly oval rather than perfectly straight.

Electrically welded pipe (ERW) has a longitudinal weld formed by resistance or induction welding without the addition of filler metal. The edges to be welded are mechanically pressed together, generating welding heat through resistance to the flow of electric current. Welds of electric welded pipe are heat treated after welding to a minimum temperature of 1,000°F or treated so that no untempered martensite remains.

Spiral welded pipes and straight seam welded pipes used for oil transportation are produced by thermal processing and rolling the steel into thin strips or plates. Hot rolling occurs at very high temperatures, above the material's recrystallization temperature, producing forgeable steel that can be formed into a variety of shapes. Cold-formed steel is made by roll forming, a metal forming process that presses sheet metal through a pair of rollers to reduce thickness, increase strength and improve surface finish.

In-line metal thickness gauges for hot and cold rolling mills provide precise, real-time measurements to ensure the finished product meets the exact specifications of the environment in which it will be used. X-ray thickness gauges are the best thickness gauge technology, providing the speed and accuracy needed to operate a hot or cold rolling mill. X-ray-based sensor systems provide extremely accurate high-speed/low-noise measurements, allowing manufacturers to save material and improve quality.

Go here to learn more about " Seamlesss Casing vs ERW Casing"