-

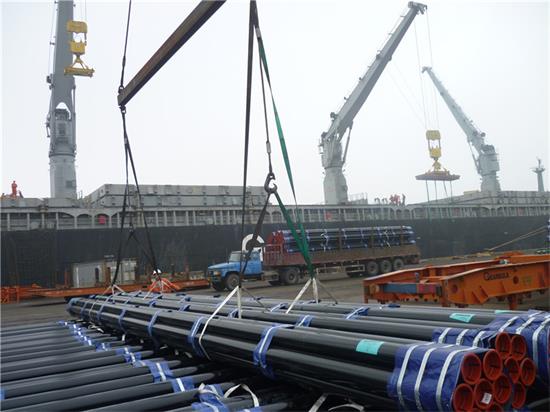

Carbon Steel Pipe

+Seamless Steel Pipe

+ERW Steel Pipe

+SSAW Steel Pipe

+LSAW Steel Pipe

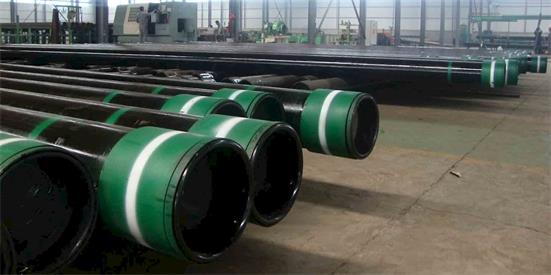

+Well Casing & Tubing

+Drill Pipe

Drill Pipe

×+Galvanized Steel Pipe

Galvanized Steel Pipe

1.Standard: ASTM A53,BS1387-85,GB/T3091-08,DIN2440,JIS-G3444,EN10255

2.Grade: Q195, Q215, Q235, Q345, S235JR, S275JR, STK400, STK500

3.Type & Zinc Coating:

Hot dip galvanized steel pipe (zinc coating: 60g/m2-275g/m2)

Pre-painted galvanized steel pipe (zinc coating: 80g/m2-275g/m2)

4.Outside diameter:

Round pipe: 17mm-273mm

Square pipe:15mm x 15mm - 400mm x 400mm

Rectangular pipe: 10mm x 20mm -200mm x 400mm

5.Wall thickness:

Round pipe: 0.6mm-12mm

Square pipe:0.6mm-20mm

Rectangular pipe: 0.6mm-20mm

6.Length:2m-5.8m/6m/12m ( We can adjust length according to your request)

×

+Bending Pipe

Inquiry Email:info@permanentsteel.com

Carbon Steel Pipe

Carbon steel pipe & tube manufactured by permanentsteel contains seamless steel pipe, erw steel pipe, lsaw steel pipe, ssaw steel pipe, casing pipe and drill pipe etc.

| Seamless sizes | Welded sizes | Application |

|

Out diameter: 1/4"-36" |

Out diameter: 21.3mm-3620mm |

API 5L, API 5CT, ASTM A53, ASTM A106, ASTM A179, ASTM A192, ASTM A252, ASTM A333, ASTM A335, ASTM A672 Water underground Sewage treatmentSteel scaffolding Transporting oil & gas Boiler and condenser tubes High-pressure applications Chemical processing |

|

Wall thickness:1.25mm-50mm |

Wall thickness:1.65-mm-65mm |

|

|

Length:3m-12m |

Length:3m-12m |

| NPS | O.D | ANSI B36.10 B36.19 Wall Thickness | ||||||||||||||

| mm | in | mm | Sch5S | Sch10S | Sch10 | Sch20 | Sch30 | Sch40S | STD | Sch40 | Sch60 | Sch80 | XS | Sch80S | Sch100 | XXS |

| 8 | 1/4 | 13.72 | - | 1.65 | - | - | - | 1.73 | 1.73 | 1.73 | - | 3.02 | 3.02 | 3.02 | - | - |

| 10 | 3/8 | 17.14 | - | 1.65 | - | - | - | 2.31 | 2.31 | 2.31 | - | 3.2 | 3.2 | 3.2 | - | - |

| 15 | 1/2 | 21.34 | 1.65 | 2.11 | - | - | - | 2.77 | 2.77 | 2.77 | - | 3.73 | 3.73 | 3.73 | - | 7.47 |

| 20 | 3/4 | 26.67 | 1.65 | 2.11 | - | - | - | 2.87 | 2.87 | 2.87 | - | 3.91 | 3.91 | 3.91 | - | 7.82 |

| 25 | 1 | 33.4 | 1.65 | 2.77 | - | - | - | 3.38 | 3.38 | 3.38 | - | 4.55 | 4.55 | 4.55 | - | 9.09 |

| 32 | 1 1/4 | 42.16 | 1.65 | 2.77 | - | - | - | 3.56 | 3.56 | 3.56 | - | 4.85 | 4.85 | 4.85 | - | 9.7 |

| 40 | 1 1/2 | 48.26 | 1.65 | 2.77 | - | - | - | 3.68 | 3.68 | 3.68 | - | 5.08 | 5.08 | 5.08 | - | 10.16 |

| 50 | 2 | 60.32 | 1.65 | 2.77 | - | - | - | 3.91 | 3.91 | 3.91 | - | 5.54 | 5.54 | 5.54 | - | 11.07 |

| 65 | 2 1/2 | 73.02 | 2.11 | 3.05 | - | - | - | 5.16 | 5.16 | 5.16 | - | 7.01 | 7.01 | 7.01 | - | 14.02 |

| 80 | 3 | 88.9 | 2.11 | 3.05 | - | - | - | 5.49 | 5.49 | 5.49 | - | 7.62 | 7.62 | 7.62 | - | 15.24 |

| 90 | 31/2 | 101.6 | 2.11 | 3.05 | - | - | - | 5.74 | 5.74 | 5.74 | - | 8.08 | 8.08 | 8.08 | - | - |

| 100 | 4 | 114.3 | 2.11 | 3.05 | - | - | - | 6.02 | 6.02 | 6.02 | - | 8.56 | 8.56 | 8.56 | - | 17.12 |

| 125 | 5 | 141.3 | 2.77 | 3.4 | - | - | - | 6.55 | 6.55 | 6.55 | - | 9.53 | 9.53 | 9.53 | - | 19.05 |

| 150 | 6 | 168.28 | 2.77 | 3.4 | - | - | - | 7.11 | 7.11 | 7.11 | - | 10.97 | 10.97 | 10.97 | - | 21.94 |

| 200 | 8 | 219.08 | 2.77 | 3.4 | - | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 12.7 | 15.09 | 22.22 |

| 250 | 10 | 273.05 | 3.4 | 3.76 | - | 6.35 | 7.8 | 9.27 | 9.27 | 9.27 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 25.4 |

| 300 | 12 | 323.85 | 3.96 | 4.57 | - | 6.35 | 8.38 | 9.52 | 9.52 | 10.3 | 14.27 | 12.7 | 12.7 | 17.48 | 21.44 | - |

| 350 | 14 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.52 | *9.52 | 9.52 | 11.13 | 15.09 | 12.7 | 12.7 | 19.05 | 23.83 | - |

| 400 | 16 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.52 | *9.52 | 9.52 | 12.7 | 16.66 | 12.7 | 12.7 | 21.44 | 26.19 | - |

| 450 | 18 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.12 | *9.52 | 9.52 | 14.27 | 19.05 | 12.7 | 12.7 | 23.82 | 29.36 | - |

| 500 | 20 | 508 | 4.78 | 5.54 | 6.35 | 7.92 | 12.7 | *9.52 | 9.52 | 15.09 | 20.62 | 12.7 | 12.7 | 26.19 | 32.54 | - |

| 550 | 22 | 558.8 | 4.78 | 5.54 | 6.35 | 7.92 | 12.7 | *9.52 | 9.52 | - | 22.22 | 12.7 | 12.7 | 28.58 | 34.92 | - |

| 600 | 24 | 609.6 | 5.54 | 6.35 | 6.35 | 7.92 | 14.27 | *9.52 | 9.52 | 17.48 | 24.61 | 12.7 | 12.7 | 30.96 | 38.89 | - |

| 650 | 26 | 660.4 | - | *7.92 | 7.92 | 12.7 | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 700 | 28 | 711.2 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 750 | 30 | 762 | 6.35 | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 800 | 32 | 812 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 17.48 | - | 12.7 | 12.7 | - | - | - |

| 850 | 34 | 863.6 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 17.48 | - | 12.7 | 12.7 | - | - | - |

| 900 | 36 | 914.4 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 19.05 | - | 12.7 | 12.7 | - | - | - |

| 950 | 38 | 965.2 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1000 | 40 | 1016 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1050 | 42 | 1066.8 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1100 | 44 | 1117.6 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1150 | 46 | 1168.4 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1200 | 48 | 1219.2 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1300 | 52 | 1320.8 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1350 | 54 | 1371.6 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1400 | 56 | 1422.4 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1500 | 60 | 1524 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1600 | 64 | 1625.6 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1700 | 68 | 1727.2 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1800 | 72 | 1828.8 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1900 | 76 | 1930.4 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 2000 | 80 | 2032 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

Standard for carbon steel pipe

|

API 5L |

for use in conveying gas, water, and oil in the natural gas and oil industries, and covers seamless and welded steel line pipe. |

|

API 5CT |

for casing and tubing |

|

ASTM A53 |

for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

ASTM A106 |

for Seamless Carbon Steel Pipe for High-Temperature Service |

|

ASTM A179 |

for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

|

ASTM A192 |

for Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

|

ASTM A213 |

for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

|

ASTM A252 |

for Welded and Seamless Steel Pipe Piles |

| ASTM A333 |

for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness |

|

ASTM A672 |

for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

|

ASTM A335 |

for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

|

DIN 17175 |

seamless steel pipes are used in boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices. |

|

DIN 1629 |

specifies the Seamless Circular Tubes of Non Alloys Steels with Special Quality Requirements. |

|

DIN 2391 |

for Cold Drawn High Precision Seamless Tube |

| DIN 2458 |

Welded Steel Pipes in Unalloyed and Low Alloy Steels for Supply Purposes |

|

EN 10210 |

Seamless steel tubes for pressure purposes |

|

BS 3059 |

Steel boiler and superheater tubes |

|

JIS G3454 |

Carbon steel pipes for pressure service |

Related mill test certification for reference, please click here