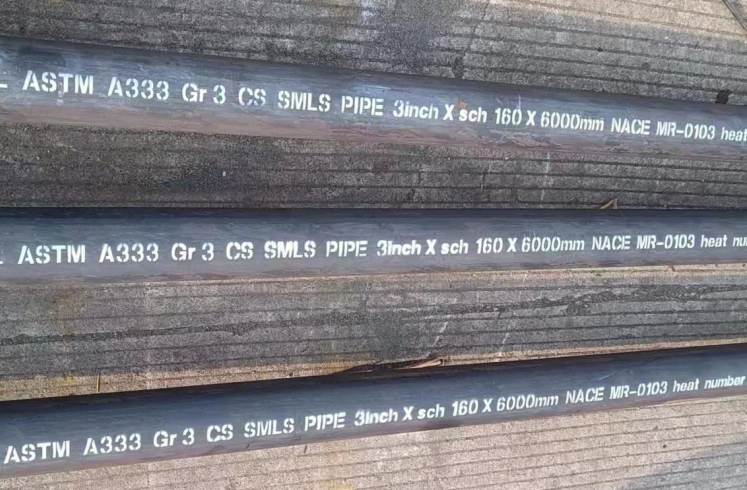

ASTM A333, ASTM A333 Low Temperature Steel Pipe

ASTM A333 covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. The pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their microstructure.

There are several grades of ferritic steel covered by this standard: Grade, Grade 3, Grade 4, Grade 6, Grade 7, Grade 8, Grade 9, Grade 10 and Grade 11. Among them, the most commonly used steel grade is Grade 6.

Chemical Requirements:

Composition, %

|

Element |

Grade 1 |

Grade 3 |

Grade 6 |

|

Carbon, max |

0.30 |

0.19 |

0.30 |

|

Manganese |

0.40 – 1.06 |

0.31 – 0.64 |

0.29 – 1.06 |

|

Phosphorous, max |

0.025 |

0.025 |

0.025 |

|

Sulfur, max |

0.025 |

0.025 |

0.025 |

|

Silicon |

|

0.18 – 0.37 |

0.10 min |

|

Nickel |

|

3.18 – 3.82 |

|

Mechanical Properties:

|

|

Grade 1 |

Grade 3 |

Grade 6 |

|

Tensile Strength, min, psi (MPa) |

55,000 (380) |

65,000 (450) |

60,000 (415) |

|

Yield Strength, min, psi (MPa) |

30,000 (205) |

35,000 (240) |

35,000 (240) |

CVN Impact (Charpy) Test:

Minimum Impact Test Temperature

Grade 1

-50 (F)

-45 (°C)

Grade 3

-150 (F)

-100 (°C)

Grade 6

-50 (F)

-45 (°C)

Tensile Requirements of ASTM A333

The material shall conform to the requirements as proscribed:

| Grade 1 | Grade 3 | Grade 6 | |||||

| psi | MPa | psi | MPa | psi | MPa | ||

| Tensile Strength, min | 55,000 | 380 | 65,000 | 450 | 60,000 | 415 | |

| Yield Strength, min | 30,000 | 205 | 35,000 | 240 | 35,000 | 240 | |

| Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | ||

| Basic minimum elongation for walls 5/16 in. [8 mm] and over in thickness, strip tests, and for all small sizes tested in full section | 35 | 35 | 30 | 20 | 30 | 16.5 | |

| When the standard round 2-in. or 50-mm gage length or proportionally smaller size test specimen with the gage length equal to 4D (4 times the diameter) is used | 28 | 20 | 22 | 14 | 22 | 12 | |

| For strip tests, a deduction for each 1/32in. [0.8 mm] decrease in wall thickness below 5/16 in. [8 mm] from the basic minimum elongation of the following percentage | 1.75 | 1.25 | 1.50 | 1.00 | 1.50 | 1.00 | |

| Wall Thickness | Grade 1 | Grade 3 | Grade 6 | ||||

| in. | mm | Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse |

| 5/16 (0.312) | 8 | 35 | 25 | 30 | 20 | 30 | 16 |

| 9/32 (.281) | 7.2 | 33 | 24 | 28 | 19 | 28 | 15 |

| 1/4 (.250) | 6.4 | 32 | 23 | 27 | 18 | 27 | 15 |

| 7/32 (.219) | 5.6 | 30 | - | 26 | - | 26 | - |

| 3/16 (.188) | 4.8 | 28 | - | 24 | - | 24 | - |

| 5/32 (.156) | 4 | 26 | - | 22 | - | 22 | - |

| 1/8 (.125) | 3.2 | 25 | - | 21 | - | 21 | - |

| 3/32 (.094) | 2.4 | 23 | - | 20 | - | 20 | - |

| 1/16 (.063) | 1.6 | 21 | - | 18 | - | 18 | - |

Heat Treatment:

All seamless and welded pipes manufactured to ASTM A333, other than Grades 8 and 11, shall be heat treated to control their microstructure in accordance with one of the following methods:

a. Normalize by heating to a uniform temperature of not less than 1500 °F [815 °C] and cool in air or in the cooling chamber of an atmosphere controlled furnace. Or normalize as above-mentioned, and, at the discretion of the manufacturer, reheat to a suitable tempering temperature.

b. For the seamless process only, reheat and control hot working and the temperature of the hot-finishing operation to a finishing temperature range from 1550 to 1750 °F [845 to 945 °C] and cool in air or in a controlled atmosphere furnace from an initial temperature of not less than 1550 °F [845 °C]. Or treat as above-mentioned, and, at the discretion of the manufacturer, reheat to a suitable tempering temperature.

c. Seamless pipe of Grades 1, 6, and 10 may be heat treated by heating to a uniform temperature of not less than 1500 °F [815 °C], followed by quenching in liquid and reheating to a suitable tempering temperature.

ASTM A333 Grade 8 pipe shall be heat treated by the manufacturer by either of the following methods: quenched + tempered; double normalized + tempered. When required, Grade 11 shall be annealed and then normalized in the range of 1400 to 1600 °F [760 to 870 °C].

Read more: Low Temperature Carbon Steel Pipe