Classification of Drill Pipes

Drill pipe is divided into three categories: kelly pipe, drill pipe and weighted drill pipe. The connection sequence is kelly (1 piece) + drill pipe (n pieces, determined by the well depth) + weighted drill pipe (n pieces, determined by the drilling tool assembly design)

kelly pipe

The kelly pipe is located at the uppermost end of the drill string and comes in two types: square and hexagonal.

effect:

1. When drilling, the kelly pipe cooperates with the core filler and the turntable core filler to transmit the ground rotation torque to the drill pipe to drive the drill string and drill bit to rotate.

2. Bear the full weight of the drill string.

3. Drilling fluid circulation channel.

structure:

Kelly pipe consists of upper and lower joints and pipe body parts. The pipe body part has two structures: square or hexagonal (most oil drilling wells have a square structure)

The upper joint is a left-hand female thread (reverse buckle). Connected to the faucet, the left-hand female thread prevents undercutting during rotation. The lower joint has a right-hand male thread and is connected to the drill pipe.

When working, the upper end of the kelly is always above the turntable surface, and the lower part is below the turntable surface.

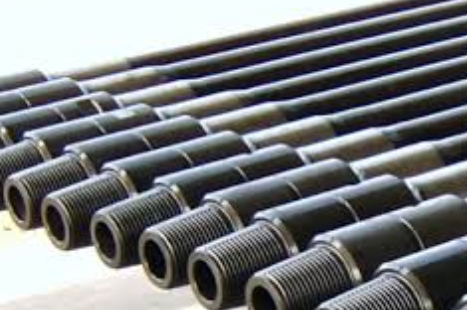

Drill pipe

effect:

Drill pipe is the basic component of drill string. Its main function is to transmit torque and transport drilling fluid, and to continuously deepen the wellbore by gradually lengthening the drill pipe. Therefore, drill pipe plays a very important role in oil drilling.

structure:

It consists of two parts: a drill pipe body and a drill pipe joint. The pipe body and joints are butt welded together by friction welding.

Made of stainless steel pipe, wall thickness is generally 9~11mm.

Weighted drill pipe

Weighted drill pipe is similar to oil drill pipe. It is also a hollow steel column with a length of about 10 meters. However, a single piece is heavier than an oil drill pipe, and its wall thickness is 2 to 3 times that of a drill pipe. The weighted drill pipe is connected between the drill pipe and the drill collar to prevent fatigue damage due to changes in the cross-section of the drill string.

It can also replace part of the drill collar. However, its suspension is simple and tripping operation is convenient, which can save tripping time.

Read more: How to Use Drill Pipe and Precautions