Common Drill Pipe Connection

What is a drill pipe?

A drill pipe is a key component of the drill string used in oil and gas drilling. It’s a hollow, thick-walled steel tube that connects the drilling rig at the surface to the drill bit at the bottom of the well, transmitting torque and rotation from the rig’s rotary table or top drive to the bit, transporting drilling fluid (mud) down to the bit and back up the annulus to carry cuttings to the surface, and supporting and controlling the weight on the bit during drilling. The drill pipe structure mainly consists of three parts: the pipe body, the tool joints, and the weld zone. The pipe body is made from high-strength seamless pipe, which provides excellent strength and durability. The tool joints, located at both ends, are thick threaded connectors used to connect each drill pipe section.

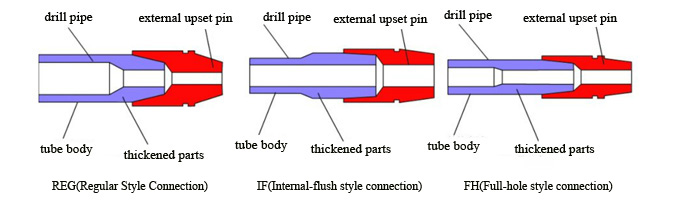

According to the threaded button type drill pipe joints, there are four types: REG(Regular style connection), IF(Internal-flush style connection), FH(Full-hole style connection); NC(Numbered connection) .

The drill pipe joint is a component of the drill pipe, divided into a male joint and a female joint, which are connected to the two ends of the drill pipe body. In order to enhance the connection strength of the joint, the wall thickness of the pipe body needs to be increased at the joint. According to the method of thickening, it can be divided into three forms: internal thickening, external thickening, and internal and external thickening.

NC is a new series, gradually replacing all IF in the API standard and all FH connectors except 5 1/2" FH. There are several interchangeable with old API connectors, mainly NC50-2 3/8"IF, NC38-3 1/2"IF, NC40-4"FH, NC46-4"IF, NC50-4 1/2"IF.

REG(Regular Style Connection)

This type of drill pipe joint thread was used to connect the inner upset drill pipe so that drill pipe diameter is smaller than the inner diameter of the thickened and the inner diameter of the thickened is smaller than the diameter of the inner tube diameter. The main purpose of API design regular style connection is applied to the bit connection. Since the drill bit is located in the end of drill string, the stress concentration phenomenon of thread is not relevant, so API retained their all specifications.IF(Internal-flush style connection)

This type of tool joint thread connects EUE or inside and outside thickened drill pipe, forming the inner diameter of the drill pipe joints, tube inner diameter and thick pipe inner diameter is equal to the inner diameter or approximate size. All specifications are used thread V-0.065 flat top and bottom triangular tooth type, which width is 0.065 inches (1.651mm). Because of this type easily lead to stress concentration, API has gradually replaced it.

FH(Full-hole style connection)

This type of joint screw connects inside and outside thickened drill pipe, forming the inner diameter of the drill pipe joint is equal to thickened end diameter and they are smaller than the inner diameter of the pipe. Although the thread specification is not much, but it has three models named V-0.065、V-0.05 and V-0.040 so that it has been widely used in kelly, drill pipe, drill collars and drill.

NC(Numbered Connection)

For drill pipe with a minimum yield strength of 75,000 PSI or greater (high-strength), the API recommends an additional designation, known as a numbered connection, or NC. NCs are designed to connect a pin and box with matching thread designations and are largely interchangeable if the grade codes match, meaning the thread pitch is the same and if the thread types are compatible. Numbered connections range from NC10 to NC77, at various intervals with corresponding inner and outer diameters. Again, it’s a good idea to check with the tool joint manufacturer to see if the NC and thread types are compatible.

The function of the connector:

As a key component for connecting drill pipes, joints play a very important role. The joints must not only be able to bear huge pressure and tension, but also have wear-resistant, corrosion-resistant properties.

There are many types of joints, among which the more common ones include threaded joints, reversible joints, non-torque joints, etc. These joints have their own characteristics and scope of application, and they need to be selected according to the operating conditions.

In addition to the function of the joint itself, the joint is often used for geological exploration and data collection, such as temperature measurement, pressure measurement, flow measurement, etc. These operations require the transmission of data through connectors and are critical to exploration and acquisition efforts.

How to connect kelly pipe and drill pipe?

1. Direct connection

Kelly pipe and drill pipe can be connected using direct connection. This method requires cleaning the surface of the kelly and drill pipe first to ensure the safety of the connection.

The advantage of direct connection is that it is simple and convenient to connect, avoids connection gaps, and can effectively reduce friction loss during rotation of the connection and resistance to sludge discharge. However, direct connection has shortcomings such as low connection strength and easy breakage. It is necessary to pay attention to the strength during connection and inspection after use.

2. Install interface connection

In addition to direct connection, you can also use the installation interface connection method. This method requires the drill pipe and kelly pipe to be installed with respective interfaces and connected through the interfaces.

The advantages of the installation interface connection are high connection strength, high efficiency, and easy replacement of connecting parts. However, installing interface connections requires more preparation work, including installing interfaces, inspecting interfaces, installing drill pipes, etc.

Whether it is direct connection or installation interface connection, you need to pay attention to the following usage precautions:

a. Before connection, the surface finish of the connecting parts and the circular runout error of the connecting parts should be checked.

b. When connecting, the drill pipe should be installed correctly and with appropriate strength, and should not be excessively loose or too tight.

c. Thorough cleaning should be carried out after connection to prevent mud from entering the connection holes.

d. During use, regularly check the wear degree of connecting parts and make necessary replacements.

Tips:

Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus. It comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3).

Drill pipe buckles are generally REG and IF buckles, others such as FH are not found in tool shops. According to the master’s experience, REG buckle and IF buckle are generally 5 buckles/in and 4 buckles/in respectively, but more than 41/2" even 4 buckles/in are REG buckles, that is to say, larger than 41/2" are generally REG buckles. , If it is less than 4-1/2", more IF buckle types are used.

Go here to learn more about " drill pipe size or casing pipe vs drill pipe"

- 【Prev】 : How to Distinguish the Thread of Oil Casing Pipe?

- 【Next】 : API Thread Specification