Advantages and Disadvantages of Large Diameter Square and Rectangular Pipes

The Introduction of Large Diameter Square and Rectangular Pipes

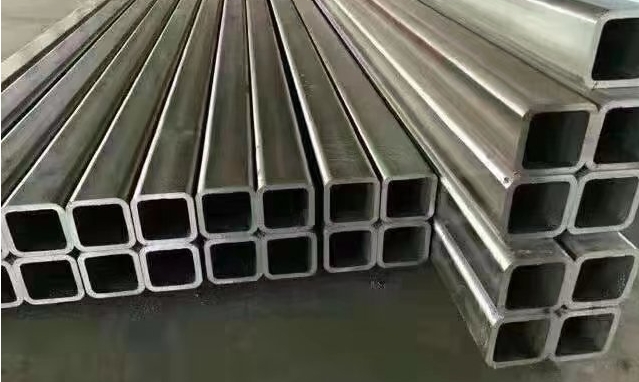

Large-diameter square and rectangular pipe is a name for square pipe, also known as square cold-formed hollow section steel, referred to as square pipe or square steel pipe. Its characteristic is a square and rectangular tube with equal side lengths. It is made of strip steel rolled through process treatment. Generally, the strip steel is unpacked, flattened, curled, and welded to form a round tube, which is then rolled into a square tube and then cut to the required length.

Large-diameter square and rectangular pipes with hollow cross-sections are generally used for pipeline transportation. Many pipelines are used to transport liquids, such as pipelines transporting crude oil, natural gas, gas, water and some solid raw materials, etc.

Production process of square and rectangular tubes

There are two main production processes for square and rectangular tubes: Welding forming process and seamless forming process. The materials used in these two processes are mainly Q235, Q345 and 20#. ( Q235 can be used in welding processes, 20# can only be used in seamless production processes, Q345 material can be used in both production processes)

The allowable deviation of the wall thickness of square and rectangular pipes shall not exceed plus or minus 10% of the nominal wall thickness when the wall thickness is not greater than 10mm. When the wall thickness is greater than 10mm, it is plus or minus 8% of the wall thickness, except for the wall thickness in corners and weld areas.

The advantages of large diameter square and rectangular pipes

1. Compared with solid construction steel materials such as round steel, pipes have a lighter net weight when their tensile strength and torsional strength are the same.

Large-diameter square and rectangular tubes are commonly used to make parts and mechanical parts, such as crude oil drilling tools, drive shafts, bicycle racks, and steel pipe racks commonly used in construction projects.

2. Using large-diameter square and rectangular tubes to make ring-shaped parts can enhance the utilization rate of raw materials, simplify the production process, and save raw materials and production and construction time, such as roller bearing throwing rings, hydraulic jack sleeves, etc.

The disadvantages of large diameter square and rectangular pipes

Large-diameter square and rectangular tubes are an indispensable raw material for various strategic weapons. Strategic weapons, gun barrels, etc. must be made of pipe materials. Steel pipes can be divided into round pipes and special-shaped pipes according to their cross-sectional area shapes. Since the circle area is the largest when the circumferences are equal, more fluid can be transported with circular tubes. In addition, the ring cross section is relatively evenly stressed when it bears internal or external radial pressure. Therefore, the vast majority of steel pipes are round pipes.

However, round tubes also have certain limitations. For example, under the condition of plane bending, round tubes are not as strong as square and rectangular tubes. Square and rectangular tubes are commonly used in some agricultural machinery frames, steel and wood furniture, etc.

Read more: Rectangular Tube Structure and its Application Areas

- 【Prev】 : Classification of Drill Pipes

- 【Next】 : A106 VS A53 Steel Pipe