Do Seamless Steel Pipes Need Galvanizing?

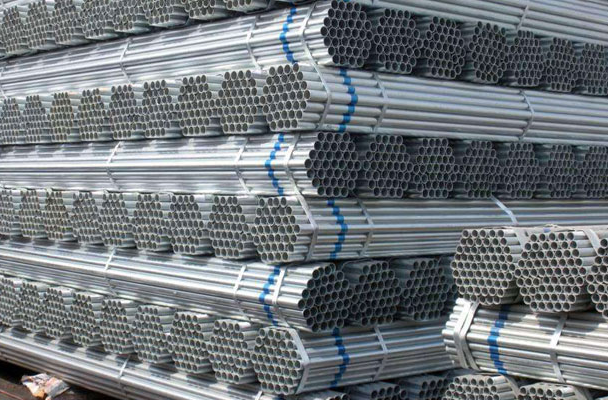

Galvanized Seamless Steel Pipes:

Galvanized seamless steel pipes are made by coating the surface of seamless steel pipes with a layer of zinc, thereby improving their corrosion resistance. The zinc coating has sacrificial anodic protection; even if the coating has minor damage, the zinc will corrode before the iron, thus protecting the substrate.

When is galvanizing necessary or strongly recommended?

Galvanizing is a standard and necessary process when seamless steel pipes are used in the following humid, corrosive, or exposed environments:

1. Outdoor atmospheric exposure: such as building steel structures, bridges, street light poles, and highway guardrails. Resistance to rain, snow, air pollutants, and ultraviolet radiation is required.

2. Buried installation: such as some water and gas pipelines. Resistance to moisture, microorganisms, and stray current corrosion in the soil is required. Often used in conjunction with cathodic protection.

3. Humid indoor environments: such as greenhouses, swimming pool structures, and indoor spaces in coastal areas. High humidity accelerates the corrosion of carbon steel.

4. Situations requiring fire safety: Galvanized coatings are more flame-retardant than paint in a fire.

When can galvanizing be omitted?

Seamless steel pipes can be used directly or with more economical rust prevention methods in the following environments:

1. Dry indoor environments: such as structural supports in dry warehouses, and the internal framework of certain mechanical equipment.

2. Short-term use or temporary projects: such as construction scaffolding (although high-end scaffolding is now commonly galvanized).

3. Subsequent full-coverage heavy-duty anti-corrosion coating: such as as a base for heavy-duty anti-corrosion coatings (such as epoxy + polyurethane). In this case, sandblasting is sufficient for rust removal; galvanizing is not necessary and may affect coating adhesion.

4. High-temperature or special media environments: Galvanized coatings fail above approximately 200°C and are unstable in strong acid and alkali environments. Heat-resistant steel, stainless steel, or special coatings should be used in such conditions.

Conclusion:

For most seamless carbon steel pipe structures exposed to atmospheric or humid environments, hot-dip galvanizing is the most cost-effective and reliable corrosion protection option. It trades a higher initial investment for decades of low maintenance costs and safety assurance. For projects in dry indoor environments or with special post-coating requirements, this cost can be saved.

- 【Prev】 : Types of Corrosion Protection for Carbon Steel Pipes

- 【Next】 : No infomation!