How to Use Drill Pipe and Precautions

Drill pipe usage methods and precautions:

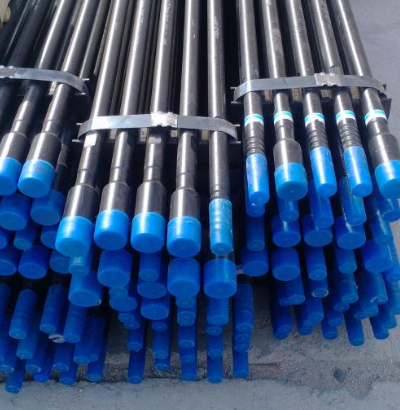

Drill pipe selection:

1. Select drill pipes of different materials and types according to the purpose of the drill pipe;2. Confirm that the specifications and length of the drill pipe meet the drilling depth requirements;

3. Check whether the surface of the drill pipe is smooth and durable, and whether there are obvious bumps or cracks.

Drill pipe assembly:

1. Assemble according to the specifications and length of the drill pipe. Be careful not to use a drill pipe that is too long or too short;

2. Confirm that the drill pipe is tightly connected, not loose, and can rotate smoothly;

3. Apply lubricating oil or grease to extend the service life of the drill pipe;

4. The length of the drill pipe should be assembled section by section according to the hole depth to ensure that the drill pipe will not break or get stuck during the drilling process.

Drill pipe use:

1. Use the correct drill bit and select the appropriate drill bit according to the hole diameter and rock drilling hardness;

2. For safe operation, you must wear protective equipment such as helmets, safety belts, and protective shoes to avoid contact with broken stones;

3. Pay attention to the rotation direction of the drill pipe. You must ensure that the drill pipe and the drill bit rotate in the same direction, otherwise the rod will be twisted or damaged;

4. Do not overload the drill pipe, otherwise its service life will be reduced.

Drill pipe maintenance:

1. When the surface of the drill pipe is obviously damaged or worn, it should be replaced in time;

2. After each use, clean the dust and dirt on the surface of the drill pipe and apply an appropriate amount of lubricating oil or grease;

3. When the drill pipe is not used for a long time, it should be placed in a dry and ventilated place and applied with anti-rust oil to prevent corrosion.

Precautions for using drill pipe:

Drill pipe is not allowed to be used under the following circumstances:

1. The drill pipe is broken, bent, etc., which seriously affects the drilling operation process and safety;

2. The drill pipe has cracks, defects, severe damage, etc., and is no longer able to withstand the required tensile or compressive force;

3. The drill pipe is deformed, twisted, damaged, etc., and cannot maintain sufficient strength and stability;

4. The drill pipe is affected by severe corrosion, erosion, etc., and the surface is severely damaged.

When using drill pipe, you need to pay attention to the following points:

1. The drill pipe must be inspected regularly to avoid the situations listed above;

2. The drill pipe must be suitable for the current drilling section or working conditions, and different types and specifications of drill pipes should be selected according to the specific well conditions;

3. The drill pipe should strictly comply with the required joint specifications and matching accuracy requirements to avoid joint loosening, falling off, etc.;

4. During the process of drilling or pulling out the drill pipe, attention must be paid to speed up and down to avoid excessive friction and wear of the drill pipe;

5. Auxiliary tools on the drill pipe (such as three-pronged pliers, wrenches, etc.) must comply with specified standards and usage requirements, and safety hazards such as loosening and sliding of tools must be strictly prevented.

Conclusion:

Drill pipe is an indispensable tool in modern drilling operations and plays an important role in drilling operations. For the use of drill pipes, we must attach great importance to details, strictly control safety risks, and avoid dangerous accidents. In order to ensure the safety of underground personnel and meet the needs of drilling operations, the quality management of drill pipes and the implementation of technical specifications should be strengthened.

Read more: Difference between Oil Casing and Drill Pipe