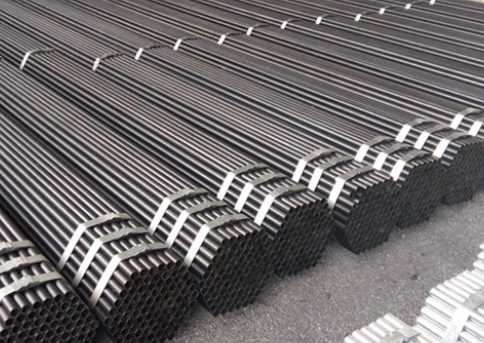

Seamless Steel Pipe for Fire Hydrant Pipes

Fire hydrant pipes are a key component in fire protection systems, and have very high requirements for the reliability, pressure resistance and corrosion resistance of the pipes. Seamless steel pipes are very suitable for fire hydrant pipes due to their unique manufacturing process.

When must seamless steel pipes be used?

The specific requirements for the use of seamless steel pipes in fire hydrant pipelines are as follows, which are organized according to current national standards:

|

System Type |

Work pressure |

Pipeline location |

Material requirements |

|

Fire hydrant system |

>1.60MPa |

Overhead pipelines |

Hot-dip galvanized seamless steel pipe must be used |

|

Fire hydrant system |

>1.60MPa |

buried pipelines |

Seamless steel pipe is recommended |

|

Fire hydrant system |

1.20~1.60MPa |

buried pipelines |

Thickened steel pipe or seamless steel pipe can be used |

Common standards

GB/T 8163 Seamless Steel Pipe for Transporting Fluids: Suitable for general fire protection systems, mostly made of 20# steel or Q345B.

GB 50974-2014 "Technical Specifications for Fire Water Supply and Fire Hydrant Systems": has systematic regulations on pipe material selection, connection methods, pressure levels, etc.

If you are designing or constructing a fire hydrant system, once the system working pressure exceeds 1.6MPa, whether it is overhead or buried, you should give priority to using hot-dip galvanized seamless steel pipes and ensure that they comply with the requirements of GB 50974-2014.

ASTM A53 "Specification for Steel Pipe, Black and Hot-Dip Galvanized, Welded and Seamless": This is a very widely used standard, among which A53 Grade B seamless steel pipe is often used in fire protection systems. It specifies the chemical composition, mechanical properties and dimensional tolerances of steel pipes.

ASTM A106, Seamless Carbon Steel Nominal Pipe for High-Temperature Service: This type of pipe is typically used for higher temperature and pressure applications, but its excellent mechanical properties also make it a reliable choice for fire mains and high-rise building fire protection systems.

ASTM A795 "Specification for Black and Hot-Dip Galvanized Welded and Seamless Steel Pipe for Fire Protection Purposes": This is a standard specifically for steel pipes used in fire protection systems, covering black steel pipes and hot-dip galvanized steel pipes, and has specific requirements for corrosion protection, marking, etc. This standard usually has two wall thicknesses: Schedule 10 and Schedule 40.

Advantages of seamless steel pipes in fire hydrant pipelines

Fire hydrant systems are usually in a static, water-filled state, but in emergencies they need to withstand higher pressures to provide sufficient water. Seamless steel pipes have the following obvious advantages over welded steel pipes:

High pressure bearing capacity: Seamless steel pipe is formed in one piece, without any welds on the pipe body, eliminating the risk of welds as potential weak points, which makes it safer and more reliable when subjected to high pressure impact and less prone to rupture or leakage.

High reliability: The manufacturing process of seamless steel pipes ensures the uniformity and overall strength of the pipe wall, which is crucial for fire protection systems that need to be in standby mode for a long time and can ensure that there will be no failures at critical moments.

Long service life: Due to its dense pipe wall and high strength, seamless steel pipes can resist corrosion more effectively after proper anti-corrosion treatment, thereby extending the service life of the entire pipeline system.

Pipeline corrosion protection is the key

Whether seamless or welded steel pipes are used, anti-corrosion treatment of fire protection pipes is of paramount importance to ensure their long-term reliability. Long-term water accumulation inside fire protection pipes is very prone to rust and scaling, which will cause two serious problems:

Blockage: Impurities caused by rust and fall off may clog the sprinkler heads or pipes, causing the fire protection system to fail.

Loss of strength: Internal corrosion weakens the pipe wall, increasing the risk of the pipe rupturing during emergency pressurization.

Therefore, fire hydrant pipes must undergo strict anti-corrosion treatment. There are currently two mainstream anti-corrosion methods:

Hot-dip galvanizing: A layer of zinc is applied to the inner and outer surfaces of steel pipes, creating a physical barrier and acting as a sacrificial anode to protect the steel pipe from corrosion.

Plastic coating: A layer of plastic, such as epoxy resin, is applied to the inner and outer surfaces of steel pipes to create a smooth, dense anti-corrosion layer. This type of pipe is commonly referred to as "fire-fighting plastic-coated steel pipe" and is currently one of the most recommended pipe materials for fire protection.

Conclusion

Seamless steel pipes are very suitable for use as fire hydrant pipes due to their excellent pressure-bearing capacity and reliability. However, it should be noted that choosing seamless steel pipes is only the first step in ensuring pipeline safety. In order to ensure that the entire fire protection system is foolproof in an emergency, it is crucial to strictly treat the pipes with anti-corrosion treatment (such as galvanizing or plastic coating inside and outside). When purchasing, please be sure to specify the material, wall thickness, implementation standards and anti-corrosion requirements of the pipes to ensure compliance with national fire protection regulations and engineering safety specifications.

Read more: Seamless Steel Pipe for Tunnel

- 【Prev】 : API 5L Grade B Pipe Specification

- 【Next】 : Casing Pipe Wall Thickness