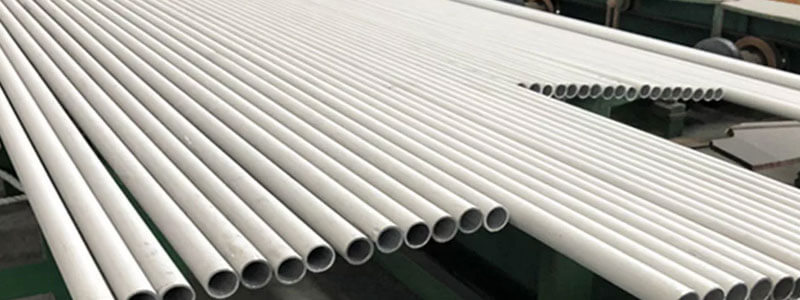

Seam pipe, Seamless pipe, Seamless stainless steel pipe

Simply put, stainless steel pipes are made of stainless steel. Stainless steel pipes are also divided into seamless stainless steel pipes and welded stainless steel pipes.

Seamless steel pipes are relative to welded steel pipes (seam pipe). Welded steel pipes are made of steel plates/coils and have welds; while seamless steel pipes are perforated and rolled from billets and have no welds.

Specifically, there are six main differences:

The manufacturing process of seamless pipes is to punch a hole in a stainless steel billet at a temperature of 2200°f. At this high temperature, the tool steel becomes soft and spirally formed from the hole after punching and drawing. In this way, the wall thickness of the pipeline is uneven and the eccentricity is high. Therefore, ASTM allows the wall thickness difference of seamless pipes to be greater than that of seamed pipes. The slotted pipe is made of precise cold-rolled sheet (with a width of 4-5 feet per coil). These cold rolled sheets usually have a maximum wall thickness difference of 0.002 inches. The steel plate is cut to a width of πd, where d is the outer diameter of the pipe. The tolerance of the wall thickness of the slit pipe is very small, and the wall thickness is very uniform throughout the circumference.

2. Welding performance

Generally, there is a certain difference in chemical composition between seamed pipes and seamless pipes. The steel composition used to produce seamless pipes is only the basic requirement of ASTM. The steel used for the production of seamed pipes contains chemical components suitable for welding. For example, the mixing of elements such as silicon, sulfur, manganese, oxygen, and triangular ferrite in a certain proportion can produce a weld melt that is easy to transfer heat during the welding process, so that the entire weld can be penetrated. Steel pipes lacking the above chemical composition, such as seamless pipes, will produce various unstable factors during the welding process, and are not easy to weld firmly and impermeably.

3. Grain size

The grain size of the metal is related to the heat treatment temperature and the time to maintain the same temperature. The grain size of the annealed slit stainless steel tube and seamless stainless steel tube are the same. If the seam pipe adopts the minimum cold treatment, the grain size of the weld is smaller than the grain size of the welded metal, otherwise, the grain size is the same.

4. Pipe strength

The strength of the pipeline depends on the alloy composition, so the seamless stainless steel pipe and the seamed stainless steel pipe containing the same alloy and the same heat treatment are essentially the same in strength. After the tensile test and the three-dimensional vibration test, the tearing of the seamed stainless steel pipe almost all occurred in a place far away from the welding point or the heated area. This is because the weld has less impurities and slightly higher nitrogen content, so the strength of the weld is better than other parts.

5. Corrosion resistance

The corrosion resistance also depends on the composition of the alloy. The corrosion resistance of seamless stainless steel pipes with the same chemical composition and fully heat-treated seamed stainless steel pipes is the same. In an acid chloride environment, the corrosion of welded joints of incompletely heat-treated steel pipes will accelerate, but this is only required for corrosion testing. In fact, the environment is not so harsh.

6. Flexibility and extensibility

The extensibility of the weld can be verified by the following test specified by ASTM: bend 45°, then bend to 90°, and then flatten along the weld; then turn the stainless steel seam pipe and repeat the above steps to make the weld bend inner diameter to 180° . The standard for welding seam quality is that no tearing or intergranular separation is allowed under 40 times magnification. The bending radius of the pipeline is controlled by the composition of the alloy, and the minimum bending radius is generally 2d. The ideal welding condition is that the weld is in a neutral or compressed state. Moreover, the pipeline should be annealed to reduce its hardness, thereby improving bending performance.

7. Price

The price of seamed stainless steel pipe is usually only half of that of stainless steel seamless pipe.

8. Wall thickness/diameter

Thin-walled stainless steel pipes with small thickness/diameter values are best produced by welding; thick-walled pipes with large thickness/diameter values are best produced by stamping.

9. Comprehensive quality

Under normal circumstances, the quality of seamed stainless steel pipes is better than seamless stainless steel pipes, because the seamed stainless steel pipes are made of accurate cold-rolled plates that have passed inspections, so any defects are limited to the weld. Seamless pipes are stamped from stainless steel blanks by punches, resulting in many tearing phenomena in the pipe wall formed by extrusion. The eddy current test shows that the defective rate of seamed stainless steel pipes is generally lower than that of seamless stainless steel pipes. Using ultrasonic testing, the background noise of seamless stainless steel pipes is so great that it is difficult to find defects. The background noise of seamed stainless steel pipes is very low, and it is easy to find defects.

Tips: ASTM A53 covers seamless and welded steel pipe with nominal wall thickness. The surface condition is usually black and hot-dipped galvanized. ASTM A53 is produced mainly for pressure and mechanical applications, and is also used for transport of steam, water, gas line pipes. A53 ERW pipe is a typical carbon steel pipe. It is largely used to convey fluids at low / medium pressures such as oil, gas, steam, water, air and also for mechanical applications.

Go here to learn more about " Identification of Seamed Steel Pipes and Seamless Steel Pipes"