Oil Country Tubular Goods (OCTG)

These products are defined in the American Petroleum Institute (API) specifications, International Specifications Organization (ISO) as well as others.

What are the types of oil pipelines?

Generally speaking, there are two types of oil pipelines: carbon steel pipes and oil-resistant rubber hoses. Many of the fixed oil pipelines we see now mostly use carbon steel pipes, while oil-resistant steel pipes play an important role in the temporary loading and unloading of active parts of oil transportation facilities. In carbon steel pipes, it can also be divided into seamless steel pipes and welded steel pipes according to different manufacturing methods, and seamless steel pipes are also divided into hot rolled and cold drawn.

1. Classification of oil pipes

Oil pipes are divided into flat oil pipes (NU), thick oil pipes (EU) and integral joint oil pipes. Flat oil pipe means that the pipe end is directly threaded and coupled with a coupling without thickening. Thickened oil pipe means that after the two pipe ends are thickened externally, they are threaded and put on the pith. The integral joint oil pipe refers to that one end is thickened with the outer thread of the car, and the other end is thickened with the inner thread of the car, and it is directly connected without a coupling.

2. The role of tubing

① Extracting oil and gas: After the oil and gas are drilled and cemented, the oil pipe is placed in the oil layer casing to extract the oil and gas to the ground.

②Water injection: When the downhole pressure is not enough, inject water into the well through the tubing

③Steam injection: In the process of thermal recovery of heavy oil, steam is injected into the downhole with insulated tubing.

④Acidizing and fracturing: In the later stage of drilling or in order to improve the production of oil and gas wells, it is necessary to input the medium or solidified material of acidification and fracturing to the oil and gas layer, and the medium and solidified material are transported through the tubing.

3. Tubing connection type: BTC, NUE, EUE, Premium

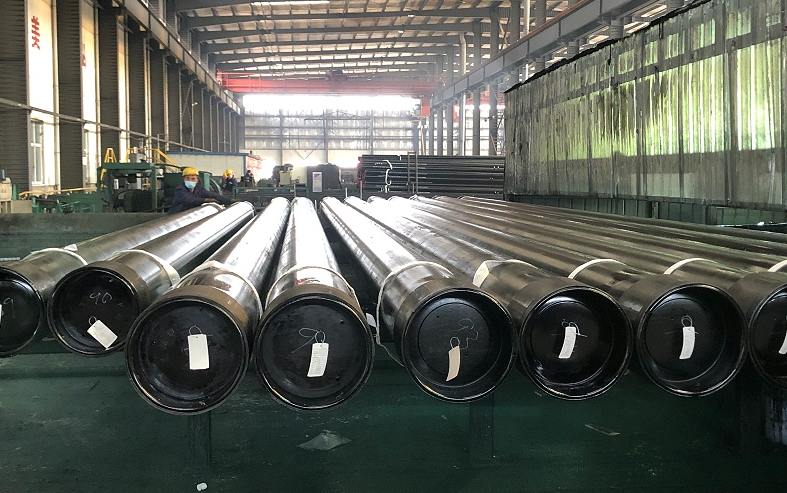

OCTG Casing

Casing pipe is a steel pipe used to support the wall of oil and gas wells to ensure the normal operation of the entire oil well after drilling and completion. Several layers of casing are used for each well according to different drilling depths and geological conditions. Cement cementing should be used after the casing is run down the well. It is different from tubing and drill pipe and cannot be reused. It is a one-time consumable material. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes.

1. Casing can be divided into: conduit, surface casing, technical casing and oil casing according to the usage.

2. Casing connection type: BTC (threaded connection support), LTC (long round thread connection), high-quality connection.

3. Casing standard

①The standard of petroleum casing refers to API5A, 5AX, 5AC of American Petroleum Institute. The steel grades are H-40, J-55, N-80, P-110, C-75, C-95, etc. The specifications are mainly 139.77.72R-2, 177.89.19R-2, 244.58.94R-2, 244.510.03R-2, 244.511.05R-2, etc.

②API stipulates that there are three lengths: R-1 is 4.88~7.62m, R-2 is 7.62~10.36m, and R-3 is 10.36m or longer.

③ Some imported goods are marked with the word LTC, that is, long threaded sleeve.

4. Technical standard of casing

(1) The length of the casing is not fixed, and its range is 8-13m. But the casing not shorter than 6m can be provided, and its quantity shall not exceed 20%.

(2) The inner and outer surfaces of the casing shall not have folds, hair lines, separation layers, cracks, folds and scars. These defects shall be completely removed to a depth not exceeding 12.5% of the nominal wall thickness.

(3) The outer surface of the coupling shall not have defects such as folds, hair lines, delamination, cracks, folds, and scarring.

(4) The surface of the casing and coupling threads should be smooth, and no burrs, tears and other defects that are enough to interrupt the thread and affect the strength and tight connection are allowed.

OCTG Drill pipe

The drill pipe is a steel pipe with ribbing at the tail, which is used to connect the surface equipment of the drilling rig and the drilling and grinding equipment or bottom hole device at the bottom of the well. The purpose of the drill pipe is to transport the drilling mud to the drill bit and together with the drill bit raise, lower or rotate the bottom hole device. Drill pipe must be able to withstand enormous internal and external pressure, twisting, bending and vibration. In the process of oil and gas extraction and refining, drill pipe can be used many times.

Drill pipe is the basic component of drill string, mainly used to transmit torque, transport drilling fluid, and continuously connect drill pipe during drilling to achieve the purpose of deepening the wellbore.

Drill pipe is divided into ordinary drill pipe, kelly and weighted drill pipe and other subdivisions. The ordinary drill pipe is the main part of the drill string. The kelly is connected to the top and the drill collar is connected to the bottom. The kelly is located at the uppermost end of the drill string. Its main function is to transmit torque, and its work is to bear the weight of the drill string. It consists of a driving part, an upper joint and a lower joint; the most commonly used is the square kelly.

The drill pipe is characterized by thin wall and light weight per unit length, mainly providing mud channel, transmitting tension and torque.

Go here to learn more about "How to Distinguish the Thread of Oil Casing Pipe? "

- 【Prev】 : Cold Drawn Seamless Steel Tubing

- 【Next】 : Oil Drilling Casing Operation Technology