Main Points of Quality Control in High Frequency Welded Pipe Welding Process

There are many factors that affect the welding quality of high-frequency welded pipes, and these factors interact and restrict each other in the same system. If one factor changes, the other factors will change with it. Therefore, when adjusting the high frequency, it is not enough to pay attention to the local adjustment of the frequency, power, current or extrusion amount of the high frequency welding machine. All aspects related to welded pipe welding are considered comprehensively, and all influencing factors are excluded one by one for adjustment.

Below we break down the main factors in the welding process of high-frequency welded pipes, which have the following eight aspects:

1. Frequency

This frequency refers to the high-frequency frequency of the high-frequency welding machine during the welding process. The frequency of high-frequency welding has a great impact on welding and quality, because the high-frequency frequency affects the distribution of current inside the raw material.

The influence of the selected frequency on welding is mainly the size of the heat-affected zone of the weld.

In terms of welding efficiency, a higher frequency should be used as much as possible. 100KHz high-frequency current can penetrate 0.1mm of ferritic steel, and 400KHz can only penetrate 0.04mm, that is, the current density distribution on the surface of the steel plate, the latter is nearly 2.5 times higher than the former.

In production practice, the frequency of 300KHz~400Khz can generally be selected when welding ordinary carbon steel materials; while welding alloy materials or thick steel plates above 10mm, a relatively lower frequency can be used, because the chromium and zinc contained in alloy steel , The skin effect of elements such as copper and aluminum is different from that of ordinary carbon steel. The metallographic phase and metal composition are different, and the frequency required for welding is also different.

At present, foreign high-frequency manufacturers have adopted the updated solid-state high-frequency technology. After setting a frequency range, it can automatically track and adjust the frequency according to the material thickness and unit speed during welding.

The higher-end Sematur frequency conversion welding machine can even gradually adjust the optimal frequency required in the frequency range, which is adjustable every 1KHz.

2. Meeting angle (VEE angle)

The meeting angle is the angle between the two sides of the strip when they enter the extrusion point. Due to the proximity effect, when the high-frequency current passes through the edge of the steel plate, the edge of the steel plate will form a preheating section and a melting section (also called a lintel), and when the lintel section is heated violently, the molten steel inside it is rapidly vaporized and blasted Splash out and form a flash, which is the so-called "fire". The size of the meeting angle (VEE angle) has the most direct impact on the melting section (welding).

The proximity effect is significant when the meeting angle is small, which is beneficial to increase the welding speed. However, if the meeting angle is too small, the preheating section and the melting section will become longer, and the result of the longer melting section will make the flashing process unstable, and deep pits and pinholes will easily form after lintel blasting, making it difficult to extrude and fuse.

When the meeting angle is too large, the melting section becomes shorter and the flash is stable, but the proximity effect is weakened, the welding efficiency is significantly reduced, and the power consumption is increased. In addition, when forming a thin-walled welded pipe, the meeting angle will elongate the edge of the pipe and produce wavy folds.

In production, we generally adjust the meeting angle within 2°-6°. The unit speed is faster when producing thin plates, and a smaller meeting angle should be used for extrusion molding; Use a larger meeting angle. Here is an empirical formula for reference: meeting angle*unit speed≮100

3. Welding method

There are two ways of high frequency welding: contact welding and induction welding.

Contact welding is a pair of copper electrodes in contact with both sides of the raw material to be welded, the induced current has good penetration, and the two effects of high-frequency current (proximity effect & skin effect) are maximized due to the direct contact between the copper electrodes and the steel plate Therefore, contact welding has high welding efficiency and low power consumption. It is widely used in high-speed and low-precision pipe production. Contact welding is generally required when producing particularly thick welded pipes.

However, contact welding has two disadvantages: one is that the copper electrode is in contact with the steel plate and wears out quickly. Second, due to the influence of the surface flatness and edge straightness of the steel plate, the current stability of contact welding is poor, and the internal and external burrs of the weld are relatively high, so it is generally not used when welding high-precision welded pipes.

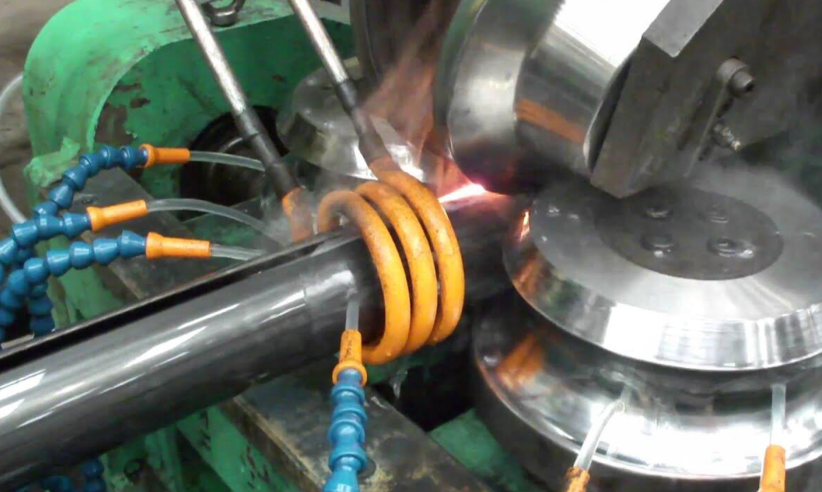

Induction welding is to wrap one or more turns of induction coils on the outside of the welded steel pipe. The effect of multi-turns is better than that of single turns, but it is more difficult to manufacture and install multi-turns induction coils.

When using induction welding, the distance between the induction coil and the steel pipe surface is small and the efficiency is high, but it is easy to cause discharge between the induction coil and the pipe. It is advisable to have a gap of 5~8mm between the coil and the surface of the steel pipe.

When induction welding is used, since the induction coil is not in contact with the steel plate, there is no wear and tear, and the induced current is relatively stable, which ensures the stability of the weld seam during welding. The surface quality of the welded steel pipe is good and the weld seam is smooth.

4. Input power

Input power control during high-frequency welding is very important, and continuous and stable input power is even more important. If the power is too small, the heating of the groove of the billet is insufficient, and the welding temperature cannot be reached, which will cause unwelded defects such as virtual welding, desoldering, and clamp welding; The temperature is much higher than the temperature required for welding, resulting in serious spattering, pinholes, slag inclusions and other defects, which are called overburning defects.

The input power during high-frequency welding should be adjusted and determined according to the pipe diameter, pipe wall thickness, speed of the molding unit, and whether to remove internal burrs. Different forming methods, different unit equipment, different metal materials, different steel grades, and even different batches of raw materials will have an impact. This needs to be considered comprehensively, summed up from the first line of production, and compiled high-quality equipment suitable for your own unit equipment. Frequency welding process.

5. Tube groove

The bevel of the tube blank is the cross-sectional shape. The general manufacturer directly enters the high-frequency welding material after slitting, and the bevel is in the shape of "I". When the thickness of the welding material is greater than 8-10mm, if this "I"-shaped groove is used, because of the relationship of the curved arc, it is necessary to melt off the inner edge layer that the tube blank first contacts, thereby forming a very high inner edge. Burrs, and it is easy to cause insufficient heating of the center layer and outer layer of the plate, which affects the welding strength of the high-frequency weld.

Therefore, when producing the rear wall pipe, it is best to go through planing or milling to make the groove be "X" shaped. Practice has proved that this kind of groove has a great relationship with uniform heating to ensure the quality of the weld.

At the same time, the selection of the groove shape also affects the adjustment of the size of the meeting angle.

Welding joint design is a relatively weak link in welding engineering design, mainly because the joint groove design of many steel structural parts is not from the hands of welding engineering technicians, and grooves with rigid set standards and poor process performance are not uncommon. The groove form plays a very important role in controlling the internal quality of the weld and the quality of the welded structure. Groove design must consider the fusion ratio of the base metal, welding space, welding position and comprehensive economic benefits and other issues.

6. Welding speed

The forming speed of the welded pipe unit is restricted by the high-frequency welding speed and sawing speed. Generally speaking, the unit speed can be opened faster, reaching 100 meters per second, and the high-frequency can also increase the speed by increasing the power.

However, for the forming of steel plates exceeding 10 mm, the forming speed of domestic production units can only reach 8-12 meters per second.

Welding speed affects welding quality. When the welding speed is increased, it is beneficial to shorten the heat-affected zone and extrude oxides from the molten groove; on the contrary, when the welding speed is very low, the heat-affected zone will widen, resulting in larger welding burrs and thickened oxide layer. Weld quality deteriorates.

7. Resistor

The function of the impedance is to strengthen the skin effect and proximity effect of the high-frequency current. The impedance is generally made of M-XO/N-XO type ferrite, and is usually made into a magnetic rod with a specification of φ10mm*(120-160)mm. Bundled in a heat-resistant, insulated casing that is cooled with water.

The setting of the impedance should match the pipe diameter to ensure the corresponding magnetic flux. To ensure the magnetic permeability of the resistor, in addition to dealing with the material requirements of the resistor, it is also necessary to ensure that the ratio of the cross-sectional area of the resistor to the cross-sectional area of the pipe diameter is sufficiently large. When producing precision high-grade pipes, it is required to remove internal burrs. The impedance can only be placed in the internal deburring device, and the cross-sectional area of the impedance will be much smaller. layout.

The distance between the resistor and the welding point also affects the welding efficiency. The gap between the resistor and the inner wall of the pipe is generally 6-15mm, and the upper limit is taken when the pipe diameter is large; the resistor should be placed concentrically with the pipe, and the distance between the head and the welding point The spacing is 10-20mm. Similarly, when the pipe diameter is large, the larger value is taken.

8. Welding extrusion force

Welding pressure is also the main parameter of high frequency welding. Theoretical calculations suggest that the welding pressure should be 100-300MPa, but it is difficult to measure the real pressure in this area in actual production. Generally, it is estimated based on experience and converted into the amount of extrusion at the edge of the pipe. Different wall thicknesses take different extrusion amounts, usually the extrusion amount below 2mm is: 0.5t~1t for 3-6mm; 0.5t for 6-10mm, and 0.3~0.5t for more than 10mm.

In the production of thick-walled pipes such as API steel pipes, weld gray spot defects often appear. Gray spot defects are refractory oxides. The extrusion allowance of the steel pipe above 6mm reaches a material thickness of 0.8~1.0, and the effect is very good.

Common problems in high frequency welding and their causes/solutions:

Reason: the output power and extrusion force are too small.

Solution: 1. Adjust the power of the high-frequency welding machine; 2. Change the groove shape of the thick material tube blank; 3. Adjust the extrusion force.

2) Ripples appear on both sides of the weld;

Reason: the meeting angle is too large

Solution: 1. Adjust the position of the guide roller; 2. Adjust the solid bending forming section; 3. Increase the welding speed.

3) The weld has deep pits and pinholes

Reason: overheated

Solution: 1. Adjust the position of the guide roller and increase the meeting angle; 2. Adjust the power; 3. Increase the welding speed.

4) Weld burrs are too high

Reason: the heat-affected zone is too wide

Solution: 1. Increase the welding speed; 2. Adjust the power.

5) Slag inclusion

Reason: input power is too large, welding speed is too slow

Solution: 1. Adjust the power; 2. Increase the welding speed

6) Cracks outside the weld

Reason: the quality of the base material is not good; too much extrusion force

Solution: 1. Ensure the quality of raw materials; 2. Adjust the extrusion force

7) Wrong welding, lap welding

Reason: poor molding accuracy

Solution: Adjust the forming die roller of the unit

In conclusion:

To sum up, high-frequency welding is a key process in the production of welded pipes. Due to systematic influencing factors and mutual constraints of these factors, we still need to explore experience in the first line of production. Each unit has its design and manufacturing differences, each operator also has different habits, and the welding quality will have obvious differences. We only have a better understanding of the basic principles of high-frequency welding, so as to better combine our own production practices,summarize the operating procedures suitable for your own unit, and implement strict control over each link, so that the quality of welded pipes can be effectively improved.

At the same time, the welded pipe equipment industry is also developing with each passing day. More equipment manufacturers are investing in research and development and experiments for automation and standardization. It is expected that in the near future, welded pipe production equipment can be made according to product specifications and uses. to automatic regulation.

Go here to learn more about "The Basic Principle of High Frequency Welding"