What is the Process of ERW Pipe Welding?

Date:2023-11-15 keywords: erw pipe welding process, electric resistance welded pipe, carbon steel erw pipe/tube

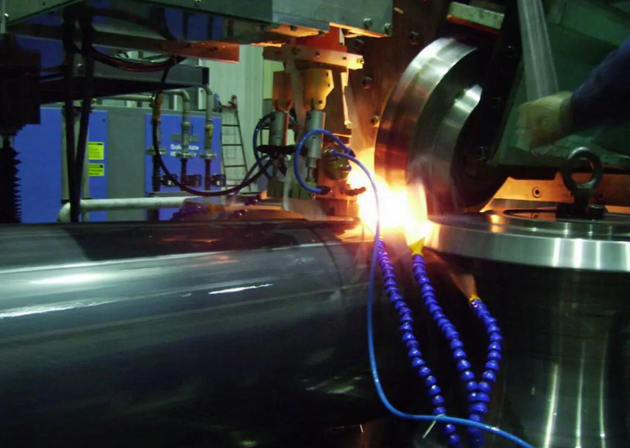

Electric resistance welded (ERW) pipe is manufactured by cold forming steel plate into a cylindrical shape. An electric current is then passed between the two edges of the steel to heat the steel to a temperature at which the edges are forced together to form a bond without the need for welding filler material.

Advantages of ERW pipe welding method:

1. One of the advantages of the ERW pipe welding method is that it is efficient and fast. Due to the use of the resistance heating principle, the heat generated during the welding process can be quickly transferred to the metal joint, causing it to melt quickly. Compared with traditional welding methods, the ERW welding method has faster welding speed and can greatly improve production efficiency.

2. The economy of the ERW pipe welding method is also one of the reasons why it is widely used. Compared with other welding methods, the ERW pipe welding method has lower equipment and material costs and is easy to operate. At the same time, due to the fast welding speed and high production efficiency, labor costs and production cycles can be reduced, and production costs can be reduced.

3. The ERW pipe welding method also has the advantages of good weld quality and high welding strength. Since the metal joints are partially melted during the welding process, the welds are formed uniformly and densely, and the welding strength is high. This welding method can also weld thicker metal plates and has better adaptability.

Limitations of ERW pipe welding methods:

However, the ERW pipe welding method also has some limitations. First of all, since current needs to be applied during the welding process, there are certain requirements for power equipment and sufficient power supply. Secondly, for some special metals, such as copper, nickel, etc., due to poor conductivity and insignificant resistance heating effect, it is not suitable to use the ERW method for welding.

Conclusion:

The ERW pipe welding method is an efficient, fast and economical metal welding method. It uses the heat generated by electric current to locally melt and connect metal joints. This method has the advantages of good weld quality and high welding strength, and has been widely used in various fields. However, it also has certain limitations. In order to overcome these limitations, it is necessary to select a suitable welding method based on specific welding needs to ensure welding quality and effect.

At the same time, Carbon steel ERW pipes have huge development potential and market competitiveness due to their high dimensional accuracy, uniform wall thickness, high production efficiency, good compressive resistance and comprehensive mechanical properties, and no perforation and cracks. There are already many applications in transportation and other aspects. With the increase in the number of domestic ERW welded pipe production lines and the accumulation of production experience, the pipe making and inspection processes of ERW welded pipes have also become increasingly perfect, thus effectively ensuring the continuous improvement of market demand and welded pipe quality. The commonly used standard for ERW welded pipes is ASTM A53 ERW.

The working principle of ERW pipe is to generate heat through the action of electric current, causing the metal joints to locally melt. During the welding process, two metal joints need to be tightly connected together and an electric current is applied. The resistance created by the current passing through the metal causes the temperature of the joint to rise, reaching the melting point and starting to melt. Then, pressure is applied to compress the two metal joints together so that they form a strong connection in the molten state. This welding method can be used to weld different types of metals, such as steel, aluminum, etc.

Advantages of ERW pipe welding method:

1. One of the advantages of the ERW pipe welding method is that it is efficient and fast. Due to the use of the resistance heating principle, the heat generated during the welding process can be quickly transferred to the metal joint, causing it to melt quickly. Compared with traditional welding methods, the ERW welding method has faster welding speed and can greatly improve production efficiency.

2. The economy of the ERW pipe welding method is also one of the reasons why it is widely used. Compared with other welding methods, the ERW pipe welding method has lower equipment and material costs and is easy to operate. At the same time, due to the fast welding speed and high production efficiency, labor costs and production cycles can be reduced, and production costs can be reduced.

3. The ERW pipe welding method also has the advantages of good weld quality and high welding strength. Since the metal joints are partially melted during the welding process, the welds are formed uniformly and densely, and the welding strength is high. This welding method can also weld thicker metal plates and has better adaptability.

Limitations of ERW pipe welding methods:

However, the ERW pipe welding method also has some limitations. First of all, since current needs to be applied during the welding process, there are certain requirements for power equipment and sufficient power supply. Secondly, for some special metals, such as copper, nickel, etc., due to poor conductivity and insignificant resistance heating effect, it is not suitable to use the ERW method for welding.

Conclusion:

The ERW pipe welding method is an efficient, fast and economical metal welding method. It uses the heat generated by electric current to locally melt and connect metal joints. This method has the advantages of good weld quality and high welding strength, and has been widely used in various fields. However, it also has certain limitations. In order to overcome these limitations, it is necessary to select a suitable welding method based on specific welding needs to ensure welding quality and effect.

At the same time, Carbon steel ERW pipes have huge development potential and market competitiveness due to their high dimensional accuracy, uniform wall thickness, high production efficiency, good compressive resistance and comprehensive mechanical properties, and no perforation and cracks. There are already many applications in transportation and other aspects. With the increase in the number of domestic ERW welded pipe production lines and the accumulation of production experience, the pipe making and inspection processes of ERW welded pipes have also become increasingly perfect, thus effectively ensuring the continuous improvement of market demand and welded pipe quality. The commonly used standard for ERW welded pipes is ASTM A53 ERW.

News Update :

Do Seamless Steel Pipes Need Galvanizing?...

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy