Welded Vs. Seamless Stainless Steel Pipe

Date:2021-03-18 keywords:Welded Vs. Seamless Stainless Steel Pipe

Stainless steel pipes can be divided into stainless steel welded pipes and stainless steel seamless pipes. Many people do not know the difference between them. How to choose? The following stainless steel manufacturers will talk about the difference between the two in detail.

1. The difference in production process

Stainless steel welded pipe: It is welded by steel plate or steel strip after being crimped and formed by the unit and mold. Different welding methods can be divided into straight seam welded pipe and spiral welded pipe.

Seamless pipe: The manufacturing process of seamless steel pipe is to punch a hole in a stainless steel billet at a temperature of 2200°f. At this high temperature, the tool steel becomes soft and spirals out of the hole after punching and drawing. Shaped out. In this way, the wall thickness of the pipeline is uneven and the eccentricity is high. The steel pipe has low precision, uneven wall thickness, low brightness on the inside and outside of the pipe, high cost of sizing, and there are pits and black spots on the inside and outside that are not easy to remove, so astm allows the wall thickness difference of seamless pipes than that of seamed pipes The difference is large, usually the pipe wall is thicker.

3. Different welding performance

Stainless steel welded pipe: due to differences in material chemical composition. The steel for the production of seamed pipes contains a chemical composition suitable for welding. For example, the mixing of elements such as silicon, sulfur, manganese, oxygen, and triangular ferrite in a certain proportion can produce a weld melt that is easy to transfer heat during the welding process, so that the entire weld can be penetrated.

Seamless pipe: The steel composition of the seamless tube is only the basic requirement of astm. Steel pipes lacking the above chemical composition, such as seamless pipes, will produce various unstable factors during the welding process, and are not easy to weld firmly and incompletely.

4. Grain size

The strength of the pipeline depends on the alloy composition, so seamless stainless steel pipes and seamed stainless steel pipes containing the same alloy and the same heat treatment are essentially the same in strength.

After the tensile test and the three-dimensional vibration test, the tearing of the seamed stainless steel pipe almost all occurred in a place far away from the welding point or the heated area. This is because the weld is less impurity and the nitrogen content is slightly higher, so the strength of the weld is better than other parts. However, ASME believes that seamed stainless steel pipes can only withstand 85% of the allowable pressure. This is mainly due to data collection earlier than the improved welding equipment used today.

6. The difference in application

Stainless steel welded pipe: With its good surface effect, it is commonly used in decorative pipes, prop pipes, and product pipes. Its pressure-bearing performance is general, mainly used for conveying water, oil, gas, air, and heating hot water or steam and other generally lower pressure fluids.

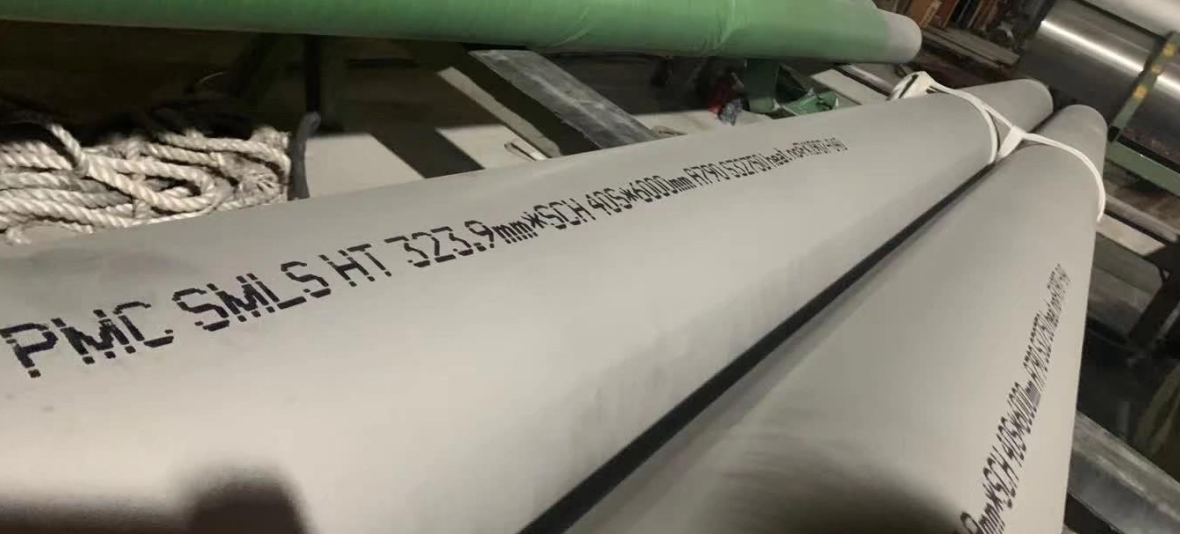

Seamless pipe: With its good corrosion resistance, pressure-bearing and high-temperature resistance, stainless steel seamless pipes can be used to transport fluid pipelines in engineering and large equipment, and can also be used to transport fluids with high temperature and high pressure on boilers in power plants and nuclear power plants. Headers and pipes, etc.

Now in some industries, welded pipes can gradually replace seamless pipes. Because of their low price and stable performance, they are gradually being loved by people. Permanent Steel Manufacturing Co., Ltd has focused on the production of stainless steel welded pipes for many years and successfully cooperated with many stainless steel seamless pipes. Demand manufacturers, they have gradually used stainless steel welded pipes.

1. The difference in production process

Stainless steel welded pipe: It is welded by steel plate or steel strip after being crimped and formed by the unit and mold. Different welding methods can be divided into straight seam welded pipe and spiral welded pipe.

Seamless pipe: It uses round steel perforated as the raw material of the tube blank, and is made by the production process of cold rolling, cold drawing or hot extrusion.

2. The difference between the appearance and concentricity of the steel pipe

Seamless pipe: The manufacturing process of seamless steel pipe is to punch a hole in a stainless steel billet at a temperature of 2200°f. At this high temperature, the tool steel becomes soft and spirals out of the hole after punching and drawing. Shaped out. In this way, the wall thickness of the pipeline is uneven and the eccentricity is high. The steel pipe has low precision, uneven wall thickness, low brightness on the inside and outside of the pipe, high cost of sizing, and there are pits and black spots on the inside and outside that are not easy to remove, so astm allows the wall thickness difference of seamless pipes than that of seamed pipes The difference is large, usually the pipe wall is thicker.

3. Different welding performance

Stainless steel welded pipe: due to differences in material chemical composition. The steel for the production of seamed pipes contains a chemical composition suitable for welding. For example, the mixing of elements such as silicon, sulfur, manganese, oxygen, and triangular ferrite in a certain proportion can produce a weld melt that is easy to transfer heat during the welding process, so that the entire weld can be penetrated.

Seamless pipe: The steel composition of the seamless tube is only the basic requirement of astm. Steel pipes lacking the above chemical composition, such as seamless pipes, will produce various unstable factors during the welding process, and are not easy to weld firmly and incompletely.

4. Grain size

The grain size of the metal is related to the heat treatment temperature and the time to maintain the same temperature. The grain size of the annealed seamed stainless steel tube and seamless stainless steel tube are the same. If the seam pipe adopts the minimum cold treatment, the grain size of the weld is smaller than the grain size of the welded metal, otherwise, the grain size is the same.

The strength of the pipeline depends on the alloy composition, so seamless stainless steel pipes and seamed stainless steel pipes containing the same alloy and the same heat treatment are essentially the same in strength.

After the tensile test and the three-dimensional vibration test, the tearing of the seamed stainless steel pipe almost all occurred in a place far away from the welding point or the heated area. This is because the weld is less impurity and the nitrogen content is slightly higher, so the strength of the weld is better than other parts. However, ASME believes that seamed stainless steel pipes can only withstand 85% of the allowable pressure. This is mainly due to data collection earlier than the improved welding equipment used today.

6. The difference in application

Stainless steel welded pipe: With its good surface effect, it is commonly used in decorative pipes, prop pipes, and product pipes. Its pressure-bearing performance is general, mainly used for conveying water, oil, gas, air, and heating hot water or steam and other generally lower pressure fluids.

Seamless pipe: With its good corrosion resistance, pressure-bearing and high-temperature resistance, stainless steel seamless pipes can be used to transport fluid pipelines in engineering and large equipment, and can also be used to transport fluids with high temperature and high pressure on boilers in power plants and nuclear power plants. Headers and pipes, etc.

Now in some industries, welded pipes can gradually replace seamless pipes. Because of their low price and stable performance, they are gradually being loved by people. Permanent Steel Manufacturing Co., Ltd has focused on the production of stainless steel welded pipes for many years and successfully cooperated with many stainless steel seamless pipes. Demand manufacturers, they have gradually used stainless steel welded pipes.

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy