Manufacturing Process of Stainless Steel Seamless Pipe

The corrosion resistance of stainless steel seamless pipes depends on the alloying elements contained in the steel. Chromium is the basic element for the corrosion resistance of stainless steel. When the chromium content in the steel reaches about 12%, the chromium interacts with the oxygen in the corrosive medium to form a very thin oxide film (self-passivation film) on the surface of the steel. , Which can prevent further corrosion of the steel matrix. In addition to chromium, the commonly used alloying elements of stainless steel seamless pipes include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc., to meet the requirements of various uses for the structure and performance of stainless steel. The following Permanent Steel Manufacturing Co.,Ltd stainless steel manufacturers explain to you the manufacturing process of stainless steel seamless steel pipes:

1. Hot rolled (extruded) seamless steel pipe:

Round tube billet → heating → piercing → three-roll cross rolling, continuous rolling or extrusion → tube removal → sizing (or reducing) → cooling → straightening → hydraulic test (Or non-destructive flaw detection) → mark → warehousing

2. The raw material for rolling seamless pipes is round pipe blanks. The round pipe blanks are cut by a cutting machine into a billet with a length of about 1 meter, and then sent to the furnace for heating via a conveyor belt. The billet is fed into the furnace and heated at a temperature of approximately 1200 degrees Celsius. The fuel is hydrogen or acetylene. The temperature control in the furnace is a key issue. After the round billet is out of the furnace, it must be pierced through a pressure punching machine. Generally, the more common piercing machine is the tapered roller piercing machine. This type of piercing machine has high production efficiency, good product quality, large perforation diameter expansion, and can wear a variety of steel types.

3. After piercing, the round tube billet is cross-rolled, continuously rolled or squeezed by three rolls. After squeezing, take off the tube and calibrate. The sizing machine uses a tapered drill bit to rotate at a high speed into the steel blank to punch holes to form a steel pipe. The inner diameter of the steel pipe is determined by the length of the outer diameter of the drill bit of the sizing machine. After the steel pipe is sized, it enters the cooling tower and is cooled by spraying water. After the steel pipe is cooled, it will be straightened. After straightening, the steel pipe is sent to the metal flaw detector (or hydraulic test) by the conveyor belt for internal flaw detection. If there are cracks, bubbles, etc. inside the steel pipe, it will be detected. After the quality inspection of steel pipes, strict manual selection is required. After the quality inspection of the steel pipe, paint the serial number, specification, production batch number, etc. with paint. It is hoisted into the warehouse by a crane.

4. Cold rolled (drawn) seamless steel pipe:

Round tube blank → heating → piercing → heading → annealing → pickling → oiling (copper plating) → multi-pass cold drawing (cold rolling) → billet tube → heat treatment → straightening →Hydraulic test (flaw detection)→Marking→Warehousing.

The rolling method of cold rolled (drawn) seamless steel pipe is more complicated than that of hot rolled (extruded seamless steel pipe). The first three steps of their production process are basically the same. The difference starts from the fourth step. After the round tube blank is emptied, it needs to be headed and annealed. After annealing, use a special acid liquid for pickling. After pickling, apply oil. Then it is followed by multiple passes of cold drawing (cold rolling) and then billeting and special heat treatment. After heat treatment, it will be straightened.

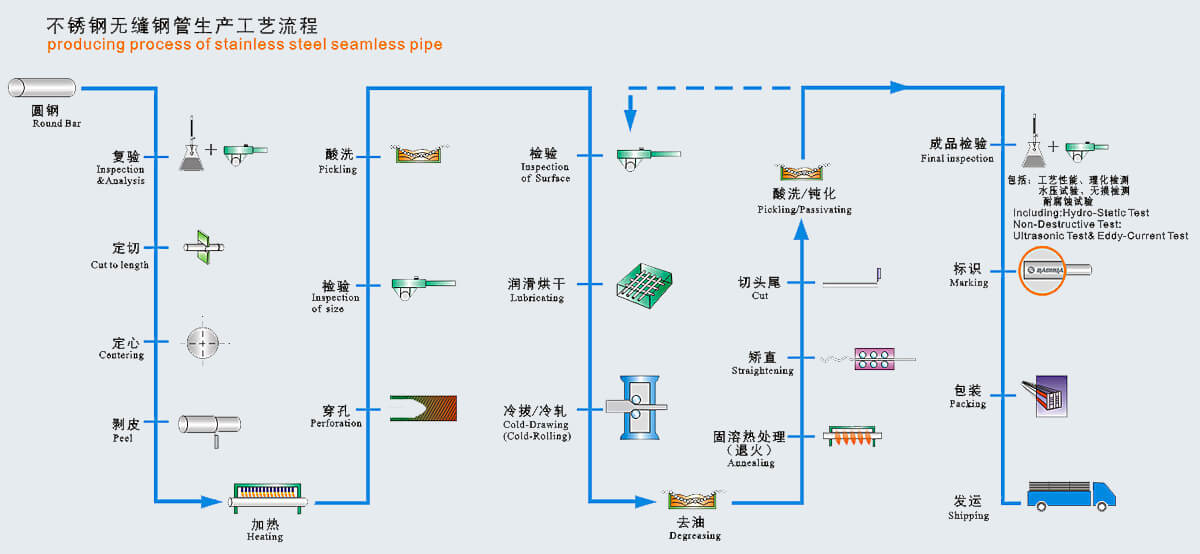

Manufacturing process of stainless steel seamless pipe:

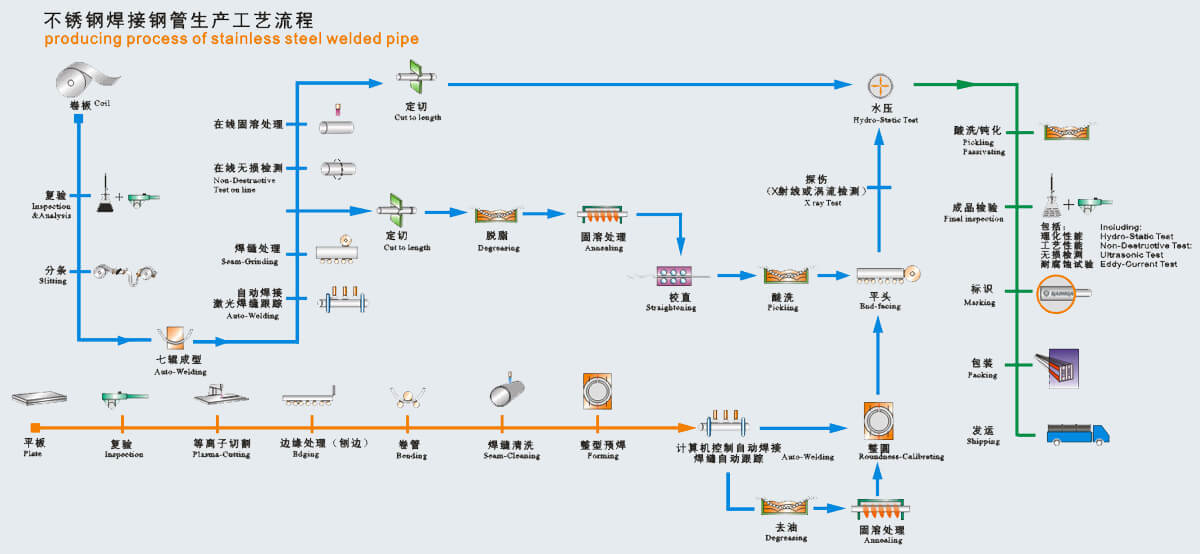

Manufacturing process of stainless steel welded pipe: