The Composition and Function of Oil Casing Pipe

Date:2024-05-20 keywords: oil casing pipe composition, casing pipe function

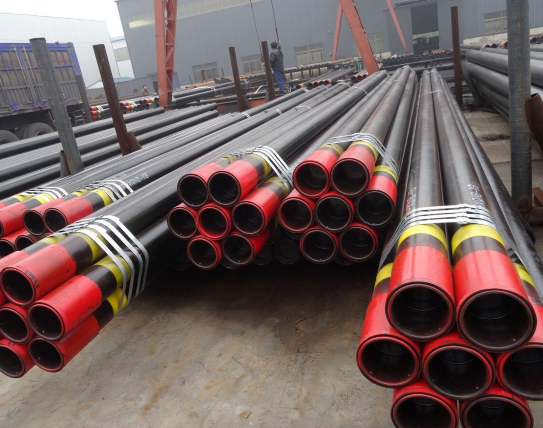

Composition of oil casing:

Usage of oil casing:

Each well uses several layers of casing based on different drilling depths and geological conditions. Cement must be used to cement the casing after it is lowered into the well. Unlike oil pipes and drill pipes, it cannot be reused and is a one-time consumable material.

According to the usage, casing can be divided into: conduit, surface casing, technical casing and oil layer casing.

The function of oil casing:

1. Fix and protect equipment such as casing and drill pipe in oil wells.

Due to the depth and pressure of oil wells, equipment such as casings and drill pipes are easily affected by environmental pressure, resulting in unstable operation and even breakage. The emergence of oil casing can effectively fix and protect these equipment so that they can work stably in the oil well, thereby improving the efficiency of the entire oil production system.

2. Prevent oil well collapse.

Oil well collapse is a very common safety hazard. If an oil well collapses, it will cause the loss of inventory in the oil well, cause pollution to the environment, and even cause losses to workers. Oil casing can prevent oil well collapse and protect the safety and stability of oil wells.

3. Prevent pollution of the external environment.

Oil casing can effectively isolate the gap between the oil well pipe wall and the oil well wall to prevent adverse environmental conditions from contaminating and eroding the internal resources of the oil well, thereby protecting the quality and value of oil resources.

The importance of oil casing in oil exploration:

As a specialized piece of equipment, the role and value of oil casing in oil exploration cannot be ignored. It can effectively fix and protect equipment such as casings and drill pipes in oil wells, prevent oil well collapse and pollution of the external environment, thereby ensuring the excavation and protection of oil resources. Therefore, oil casing has irreplaceable importance in the current field of oil exploration.

Read more: Casing Pipe Manufacturing Process

News Update :

Types of Corrosion Protection for Carbon Steel Pipes...

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy