Steel Casing Pipe VS. Tubing

Oil Tubing:

Oil tubing & pipe is a pipe that is run into the oil well casing during normal production of the oil well. In the self-blowout well, the oil flow is injected into the ground through the oil pipeline and enters the gathering and transportation process. In mechanical production wells, oil pipes, sucker rods, and deep well pumps (i.e., "three pumping" equipment) are combined to pump oil to the surface and enter the gathering and transportation process.

Steel grade of oil tubing:

The steel grades of tubing and casing are the same, mainly including J55, K55, N80, L80, P110, etc.

Oil tubing classification:

1. No thickening of oil tubing (NU)

2. Externally thickened oil tubing (EU)

3. Integral joint oil tubing (IJ)

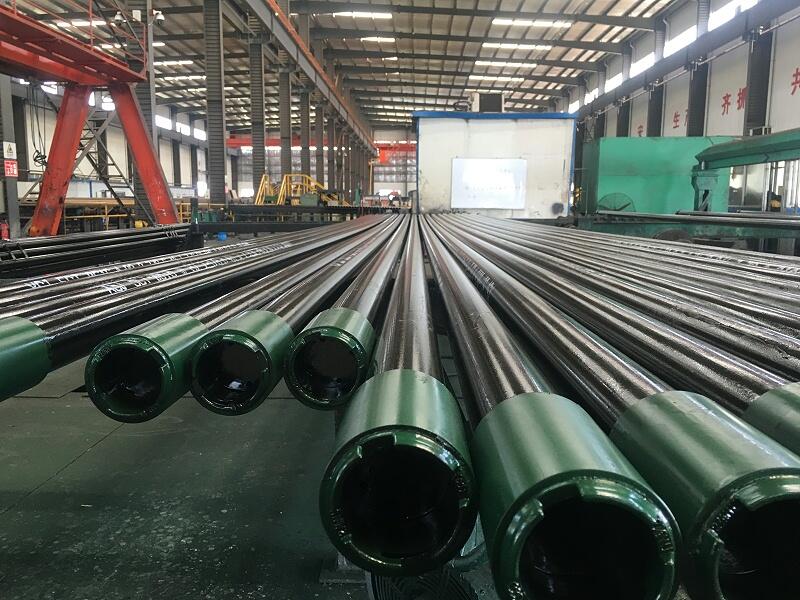

Special oil tubes are mainly used for drilling oil and gas wells and transporting oil and gas. It includes oil drill pipe, steel casing and pumping pipe. Oil drill pipe is mainly used to connect drill collars and drill bits to transmit drilling power. Steel casing is mainly used to support the well wall during the drilling process and after well completion to ensure the normal operation of the entire oil well during the drilling process and after well completion. Oil pumping pipes mainly transport oil and natural gas from the bottom of the oil well to the surface.

Steel Casing Pipe:

Steel grade of petroleum steel casing pipe:

According to the strength of the steel itself, casing can be divided into different steel grades, namely H40, J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Different well conditions and well depths require different steel grades. In corrosive environments, the casing itself is also required to have corrosion resistance. In places with complex geological conditions, the casing is also required to have anti-collapse properties.

Steel casing end processing forms: short round thread, long round thread, partial trapezoidal thread, special buckle, etc.

Classification of steel casing pipe:

Different types of casing used in oil extraction process:

1. Surface oil casing: protects drilling wells from contamination by shallow water and gas layers, supports wellhead equipment and maintains the weight of other layers of casing.

2. Technical oil casing: Separate the pressure at different levels to facilitate the normal circulation of drilling fluid and protect the production casing. Install anti-burst devices, anti-leak devices and tail pipes in the drilling well.

3. Oil layer oil casing: export oil and natural gas from the reservoir below the surface. Used to protect drilling wells and layer drilling mud. When producing oil casing, the outer diameter usually ranges from 114.3 mm to 508 mm.

The main functions of steel casing pipe:

1. Reinforce the well wall to avoid collapse of the geological structure;

2. Isolate different oil layers and water layers to achieve layered mining;

3. It is conducive to the implementation of fracturing, acidification and other measures and maintenance operations.

4. Form an oil flow channel and cooperate with the oil pipeline to achieve the purpose of oil production.

The sequence of oil extraction is: After the oil well is drilled, the casing is run in, the steel casing and the well wall are sealed with cement, and the oil pipe is run in the steel casing. The oil pipe is equipped with oil packers, pumps and other special downhole tools. A sucker rod is placed in the oil pipe, and the sucker rod pulls the piston of the pump to move up and down repeatedly. That way, the oil can be pumped to the ground.

Difference between Oil Tubing and steel Casing Pipe:

1. Different uses

Tubing is a smooth pipe used to carry oil and gas to the surface and is located shallowly in a well. Casing is a pipe that reinforces the well wall and stabilizes the formation. It is used to fill the well wall space and prevent well wall collapse and leakage.

2. Different structures

Generally speaking, the diameter of oil tubing is relatively small, and the maximum size of oil tubing is 4 1/2". Oil tubes are usually made of a lightweight steel pipe with a smooth surface and a relatively simple structure. The casing needs to withstand greater weight and pressure, so it is usually made of thicker steel and has some support structure to increase its stability. Casing is also divided into multi-stage casing, which is a combination of cylindrical pipes of different diameters. Multi-stage casing is mainly used to support drilling operations and strengthen the well wall.

3. Different performance

There are certain differences in the application environments of tubing and casing, so their performance is also different. Oil tubes need to withstand the impact and corrosion caused by the transported fluid, so the surface needs to undergo more complex treatments to improve its corrosion resistance and wear resistance. The casing needs to withstand higher pressures, so it is usually made of more corrosion-resistant materials and reinforced on the surface.

In oil drilling, the differences in structure and performance of tubing and casing determine their application range and usage. Choosing the right tubing and casing can greatly improve the efficiency and success rate of drilling.

The role of oil tubing and steel casing pipe in oil well drilling and oil and gas production:

During oil well drilling, tubing is mainly used to discharge cuttings and mud from the well and support the drill bit and weight. At the same time, oil pipes can also be used as production pipes and water injection pipes. Casing is mainly used to stabilize the well wall and line the hole.

In the oil and gas extraction process, tubing is mainly used to transport oil and gas from the well to the surface, and equipment can be deployed at the wellhead for production testing. As one of the main structures of the oil well, casing improves the stability of the wellbore, prevents wellbore collapse and collapse, and ensures production safety.

Generally speaking, oil tubing and steel casing pipe plays an important role in oil well drilling and oil and gas production. Although the two have different functions and roles, they are both essential oil well pipelines.