Process Flow of Hot-rolled Steel Strip for Petroleum Casing

The technological production process of the hot-rolled steel strip for J55 oil casing pipe is as follows: molten iron magnesium-based desulfurization-top-bottom re-blowing converter-alloying-LF refining-calcium feeding line-soft blowing-medium-broadband conventional grid slab continuous casting-cast slab cutting One heating furnace, one rough rolling, 5 passes, rolling, heat preservation, and finishing rolling, 7 passes, controlled rolling, laminar flow cooling, coiling, and packaging.

According to the use of J55 oil casing steel strip, considering its strength, plasticity, toughness and weldability, it is difficult to improve the strength of J55 grade steel strip with low carbon and high manganese steel strip, but the plasticity and toughness are better. Under the conditions of controlled rolling and controlled cooling, it is feasible to use the existing technology to produce hot-rolled strip steel for J55 oil casing, and it has mass production capacity at present.

What details should be paid attention to in the production of oil casing:

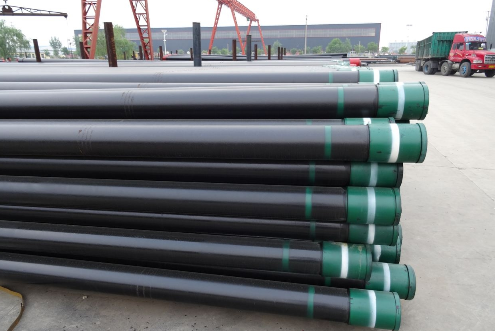

(2) The inner and outer surfaces of the oil casing shall not have folds, hairlines, delamination cracks, folds and scars. These defects should be completely removed to a depth not exceeding the nominal wall thickness

of 12.5%.

(3) The outer surface of the coupling shall not have defects such as folds, hair lines, layer cracks, folds, and scarring.

(4) The surface of the oil casing and coupling threads should be smooth, and no burrs, tears and other defects sufficient to interrupt the thread and affect the strength and tight connection are allowed.

Go here to learn more about " Casing Pipe Manufacturing Process"