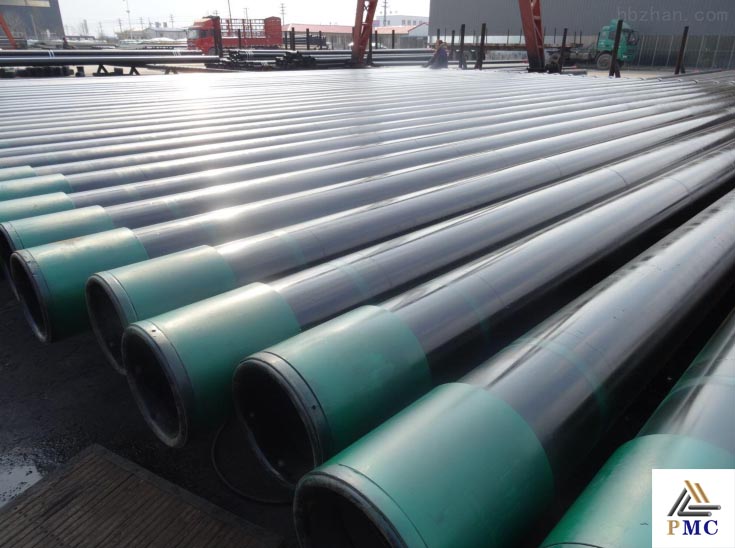

Oil Casing Pipe Maintenance and Anti-corrosion Countermeasures

Date:2023-07-05 keywords: oil casing pipe maintenance, oil casing pipe anti-corrosion

1) How to maintain the oil casing pipe?

Oil casing pipe is one of the important equipment in oil exploration, development and production. It is used as a connection between the well wall and the oil pipe to fix the oil pipe and seal the wellbore to ensure the normal production of the oil field. Therefore, the maintenance of oil casing is very important. The following are some common methods and precautions.

1. Cleaning

During the use of oil casing, it is necessary to regularly clean the surface and interior of the casing to prevent accumulation and impurities from affecting work efficiency, and check for corrosion or damage. When cleaning, care should be taken to use tools such as soft brushes, and do not use wire brushes or hard objects to wipe, so as not to scratch the surface of the casing.

2. Coating protection

3. Use an abrasive

In order to reduce the wear of the casing, some lubricants and friction agents are often used, such as graphite paint, polytetrafluoroethylene (PTFE), etc. These chemicals reduce bushing wear and increase service life, while also protecting the bushing from corrosion.

4. Keep dry

Oil casing must be kept dry during storage and use to avoid problems such as corrosion. For oil casings stored for a long time, it should be prevented from being exposed to high humidity environment for a long time, and attention should be paid to regularly checking its status to ensure that it can be repaired and replaced in time when necessary.

5. Maintenance

When the service life of the oil casing reaches a certain time limit or problems such as damage and aging occur, it needs to be repaired and replaced. Regular inspection and maintenance of oil casing is of great significance to ensure the safe production and economic benefits of oil fields.

2) How to anti-corrosion oil casing pipe?

1. First of all, do a good job in meeting water quality standards, and strictly monitor and manage water quality. Carry out cleaning and separate injection, strengthen the cleaning of the main water pipeline, ensure that the water quality in the station and the bottom of the well meets the standard, and reduce the introduction of corrosion sources into the annular space;

2. For the water injection wells that have been newly put into production, the annulus protection fluid, which is mainly sterilized, is adopted, and a system is formed to add it regularly;

3. In view of the accelerated effect of mechanical abrasion on the corrosion of oil casing, it is recommended to add a rubber ring on the tubing coupling or add a centralizer to the serious part of the well deviation, so as to avoid the tubing scratching the casing and the casing during operation and water injection. One side contacts the casing;

4. In view of the serious corrosion of sub-scale bacteria and the slow growth and killing of SRB at high temperature, high-temperature water or steam at 100 degrees Celsius can be injected into the annular space regularly to kill the sub-scale SRB;

5. It is not recommended to promote the use of cathodic protection and coated casing before the corrosion in the casing of the water injection well is effectively controlled.

Oil casing pipe is one of the important equipment in oil exploration, development and production. It is used as a connection between the well wall and the oil pipe to fix the oil pipe and seal the wellbore to ensure the normal production of the oil field. Therefore, the maintenance of oil casing is very important. The following are some common methods and precautions.

1. Cleaning

During the use of oil casing, it is necessary to regularly clean the surface and interior of the casing to prevent accumulation and impurities from affecting work efficiency, and check for corrosion or damage. When cleaning, care should be taken to use tools such as soft brushes, and do not use wire brushes or hard objects to wipe, so as not to scratch the surface of the casing.

2. Coating protection

In order to resist the corrosion and erosion of the oil casing by the external environment, the surface can be protected by coating. Commonly used protective coatings include epoxy resin, asphalt, etc., which can effectively prevent the casing from being corroded in various harsh environments.

3. Use an abrasive

In order to reduce the wear of the casing, some lubricants and friction agents are often used, such as graphite paint, polytetrafluoroethylene (PTFE), etc. These chemicals reduce bushing wear and increase service life, while also protecting the bushing from corrosion.

4. Keep dry

Oil casing must be kept dry during storage and use to avoid problems such as corrosion. For oil casings stored for a long time, it should be prevented from being exposed to high humidity environment for a long time, and attention should be paid to regularly checking its status to ensure that it can be repaired and replaced in time when necessary.

5. Maintenance

When the service life of the oil casing reaches a certain time limit or problems such as damage and aging occur, it needs to be repaired and replaced. Regular inspection and maintenance of oil casing is of great significance to ensure the safe production and economic benefits of oil fields.

2) How to anti-corrosion oil casing pipe?

1. First of all, do a good job in meeting water quality standards, and strictly monitor and manage water quality. Carry out cleaning and separate injection, strengthen the cleaning of the main water pipeline, ensure that the water quality in the station and the bottom of the well meets the standard, and reduce the introduction of corrosion sources into the annular space;

2. For the water injection wells that have been newly put into production, the annulus protection fluid, which is mainly sterilized, is adopted, and a system is formed to add it regularly;

3. In view of the accelerated effect of mechanical abrasion on the corrosion of oil casing, it is recommended to add a rubber ring on the tubing coupling or add a centralizer to the serious part of the well deviation, so as to avoid the tubing scratching the casing and the casing during operation and water injection. One side contacts the casing;

4. In view of the serious corrosion of sub-scale bacteria and the slow growth and killing of SRB at high temperature, high-temperature water or steam at 100 degrees Celsius can be injected into the annular space regularly to kill the sub-scale SRB;

5. It is not recommended to promote the use of cathodic protection and coated casing before the corrosion in the casing of the water injection well is effectively controlled.

In short, the oil casing is a very important equipment in the oil industry, and its maintenance and maintenance are very important. By adopting the above method, the service life of the oil casing can be guaranteed, and the production efficiency and safety of the oil field can be improved.

Go here to learn more about " Casing Pipe Manufacturing Process"

News Update :

Types of Corrosion Protection for Carbon Steel Pipes...

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy