How to Distinguish the Pros and Cons of Seamless Steel Pipes with the Naked Eye?

1. Inferior quality seamless steel pipes are prone to scars.

Mainly due to two reasons:

(1) Inferior seamless steel pipes have many impurities and uneven materials.

(2) Inferior pipe manufacturers have simple guide and guard equipment, which is especially easy to stick to steel, and the pipes containing impurities are prone to scars after biting into the roll.

2. Inferior quality seamless steel pipes are prone to pipe folding.

The so-called folding refers to the various fold lines formed on the surface of seamless steel pipes. Such defects often run through the longitudinal direction of the entire product. The reason for the folding is that in order to increase the output, the manufacturer pursues high efficiency, and the pressing amount is too large during the production process, which produces ears, and it is easy to produce folding in the next rolling process. The folded product is prone to cracking after bending, which causes the strength of the pipe to be greatly reduced.

3. Inferior quality seamless steel pipes are prone to scratches. The reason is that the production equipment of inferior steel pipe manufacturers is simple and the products are prone to burrs and scratches on the surface of the steel. Deep scratches will reduce the strength of the steel.

4. Inferior quality seamless steel pipes often have pitting on the surface.

The pitted surface is a defect of irregular unevenness on the surface of the steel due to severe wear of the rolling groove. Because inferior steel pipe manufacturers are pursuing profits, the groove rolling often exceeds the standard.

5. Inferior pipes are prone to cracks on the surface. One of the reasons is that the blanks are adobes, which have many pores. In the process of cooling, due to the effect of thermal stress, cracks are generated, and there are cracks after rolling.

6. Inferior seamless steel pipes have no metallic luster and are light red or similar to pig iron. There are two reasons:

(1) Its blank is adobe.

(2) The rolling temperature of low-quality materials is not standard. Their steel temperature is visually inspected, so that rolling cannot be carried out in the specified austenite area, and the performance of the steel will naturally not meet the standard.

7. Inferior quality seamless steel pipes have thin and low transverse ribs and often appear dissatisfied. The reason is that in order to achieve a large negative tolerance, the reduction of the first few passes of the finished product is too large, the iron type is too small, and the hole type is not full.

9. Inferior seamless steel pipes have irregular cross-sections and large ellipticity errors. The reason is that in order to increase the output, the reduction of the first two passes of the finished roll is too large for the manufacturer. The strength of this kind of seamless steel pipe is greatly reduced, and it does not meet the standard of seamless steel pipe dimensions.

10. The material of inferior seamless steel pipe contains many impurities, the density of steel is too small, and the size is out of tolerance seriously, so it can be weighed and checked without a vernier caliper. For example, for rebar #20, the national standard stipulates that the maximum negative tolerance is 5%. When the fixed length is 9M, its single theoretical weight is 120 kg, and its minimum weight should be: 120 X (l-5%) = 114 kilograms, the actual weight of a single piece weighed out is smaller than 114 kilograms, it is inferior steel, because its negative tolerance exceeds 5%. Generally speaking, the effect of phasing weighing will be better, mainly considering the problem of cumulative error and probability theory.

11. The inner diameter size of inferior seamless steel pipe fluctuates greatly, the reason is:

(1) The steel temperature is unstable and has a yin and yang side.

(2) The composition of steel is not uniform.

(3) Due to the simple equipment and low foundation strength, the rolling mill bounces greatly. There will be large changes in the same week, and such seamless steel pipes are prone to breakage due to uneven stress.

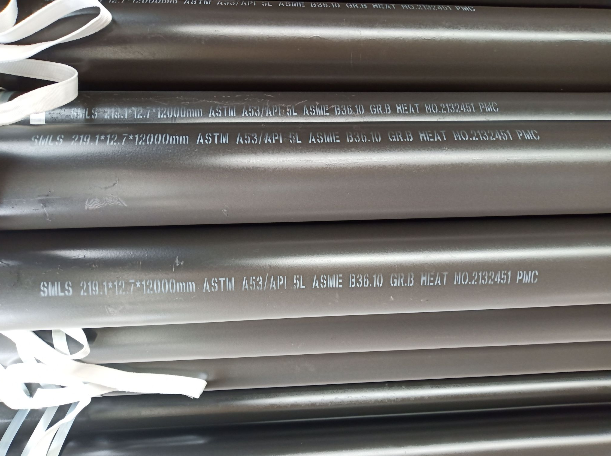

12. The trademarks and printing of high-quality seamless steel pipes are relatively standardized.

13. Inferior seamless steel pipe manufacturers have loose packaging because they have no driving. The side is oval.

Permanent Steel Manufacturing Co.,Ltd (seamless pipe for sale) have years of experience in manufacturing of carbon steel pipe, stainless steel tube, hollow section, pipe fittings.(Fluid Pipe/Boiler Tube/Fire Pipe/Line Pipe/Structure Tube)