ERW Casing, API Steel Casing Pipe

ERW (Electric Resistant Weld) steel pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel plate (coil) of ERW welded pipe is made of low-carbon microalloy steel rolled by TMCP (Thermo-Mechanical Control Process).

The ERW casing is a large diameter pipeline that acts as a fixed oil well and natural gas well or well. The casing is inserted into the borehole and fixed with cement to prevent the borehole from separating the formation from the borehole and ensure drilling mud circulation for drilling.

Different types of casing used in the oil production process: the surface protection wells of the ERW casing are not affected by shallow water and shallow air, support the wellhead equipment and maintain the other layers of the casing. The technology ERW casing separates different levels of pressure to protect normal drilling fluid circulation and production casing. In order to install explosion-proof devices, leak proof devices and tail pipes in boreholes. The oil casing outputs oil and natural gas from the storage layer under the ground. Used for protective wells and stratified drilling mud. In the production of ERW bushing, the outer diameter is usually between 114.3 millimeters and 508 millimeters.

Features of ERW Casing:

ERW casing is also called T.U.F tube due to its characteristics:

Tough material-Uniform properties -Free from defects.

1. The ERW pipe has high dimensional accuracy, good surface quality, uniform wall thickness, and high anti-extrusion performance of the casing;

2. The ERW pipe base material has less impurities, uniform structure, good material toughness, and the high toughness of the casing can meet the needs of special well conditions in the oil field;

3. The ERW pipe has a large diameter span. Compared with seamless casing, it has certain economic advantages in the large diameter (above 219mm) specification.

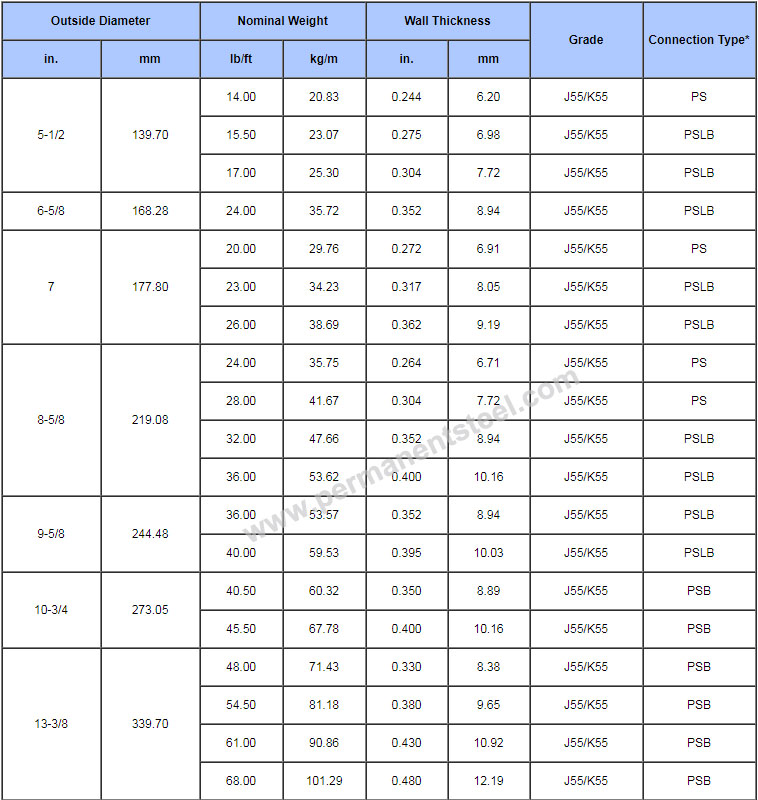

Technical specifications of ERW Casing:

1. First of all, make sure that the water quality meets the standards, and strictly monitor and manage the water quality. Implement cleaning and separate injection, strengthen the cleaning of main water pipelines, ensure that the water quality in the station and the bottom of the well meets the standard, and reduce the introduction of corrosion sources into the annular space;

3. In view of the accelerated effect of mechanical scratches on the corrosion of oil casing, it is recommended to add a rubber ring to the tubing coupling or add a centralizer to the serious part of the well deviation to avoid the tubing scratching the casing and the tubing during the operation and water injection. One side touches the casing;

4. In view of the severe corrosion of bacteria under the scale and the slow growth and killing of SRB at high temperature, high temperature water or steam of 100 degrees Celsius can be injected into the annulus regularly to kill the SRB under scale;

5. It is not recommended to promote the use of cathodic protection and coated casing before the corrosion in the casing of the water injection well is effectively controlled.

Tips: ERW welded pipe is formed by rolling strip and welding the seam, with tighter dimensional tolerances and less weight. The weld seam is heat treated after welding that no untempered martensite remains, and the weld flash can be removed from both inner and outer surfaces.

ASTM A53 ERW steel pipe is a typical carbon steel pipe. It is largely used to convey fluids at low / medium pressures such as oil, gas, steam, water, air and also for mechanical applications.

Go here if you are looking for the "Seamless Casing vs. ERW Casing".