Seamless Casing, API Steel Casing Pipe Connection

Seamless Casing - Casing made of seamless steel pipe as raw material;

Seamless steel tubes refer to steel tubes manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There are no welds on the pipe body itself.

Casing and tubing play a major role in the oil and gas exploration & production. While casing form the wall of the well and is a permanent structure, tubing runs inside the casing through which oil or gas is brought upto the surface. Both are critical components of the oil or gas well as failure will result in huge loss. The requirements can be very stringent as the depth of the well increases. Sometimes the well has to go through rocky layers and sometimes inside the sea. Size, grade, quantity of pipes depend on the design of the well which is based on product, depth, pressure, volume & environment. With most of the easy exploration areas exhausted & exploration going into difficult areas, the demand for higher grade & better quality pipes is increasing every year.

Seamless casing and connection is considered the most commonly utilized oil-field casing today. Seamless casing is produced in a pipe mill using a billet, a solid cylindrical piece of steel.

The manufacturing process takes place through the exposure of the billet to high temperature; billet penetration using a mandrel; passage of the billet into the rollers and internal mandrels to size it up; treatment of the tube with heat; and straightening and final sizing.

Seamless Casing and Connection Features

The dimensional and wall thickness specifications of oil well seamless casing ranges from 1/8 inch to 26 inches OD. It is particularly suited for high-pressure operations, including oil and gas exploration and drilling, hydrocarbon industries and refineries, and oil and gas transportation.The threading of the connections of the seamless casing may be done either by the manufacturer or by other companies. Ensuring the uniformity of the seamless casing wall thickness is a challenge to manufacturers. The production process may cause slight eccentricity to the cross section of the seamless casing wall.

Seamless Casing and Connection over Welded Type

Seamless casing and connection presents advantages over the welded type. The primary advantage of the seamless casing for oil well is the absence of a weld seam, which is considered a weak spot that can pose risks of failure and corrosion. In addition, better roundness is seen with seamless casing and connection. Lastly, the possibility of having a weak seam is omitted.

The only weak points associated with seamless casing and connection for oil wells are the disparities in wall thickness, challenges in the production process, and the higher costs.

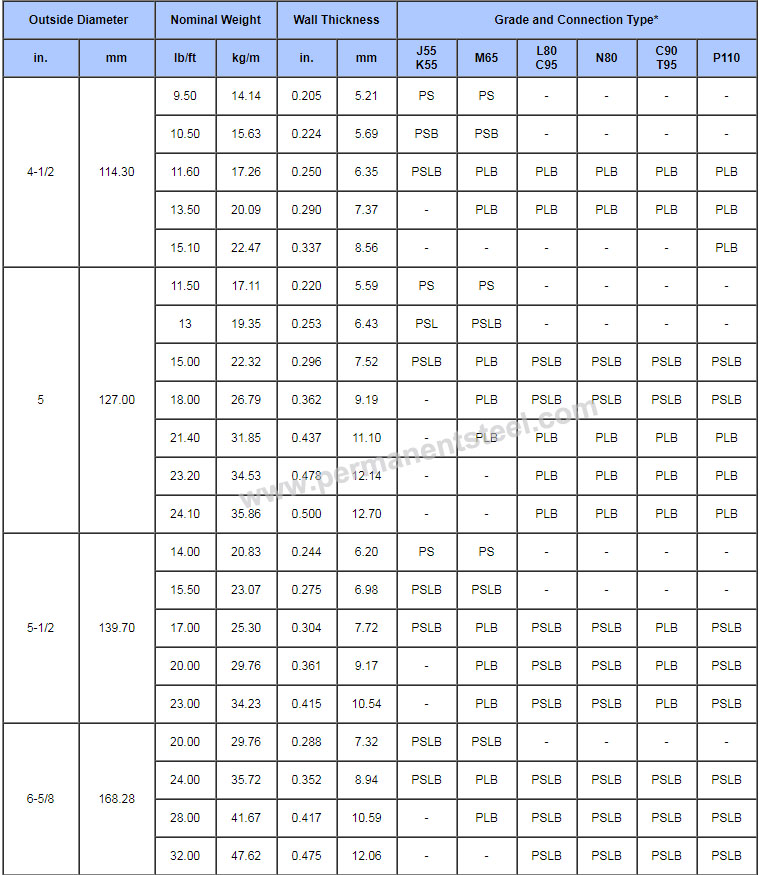

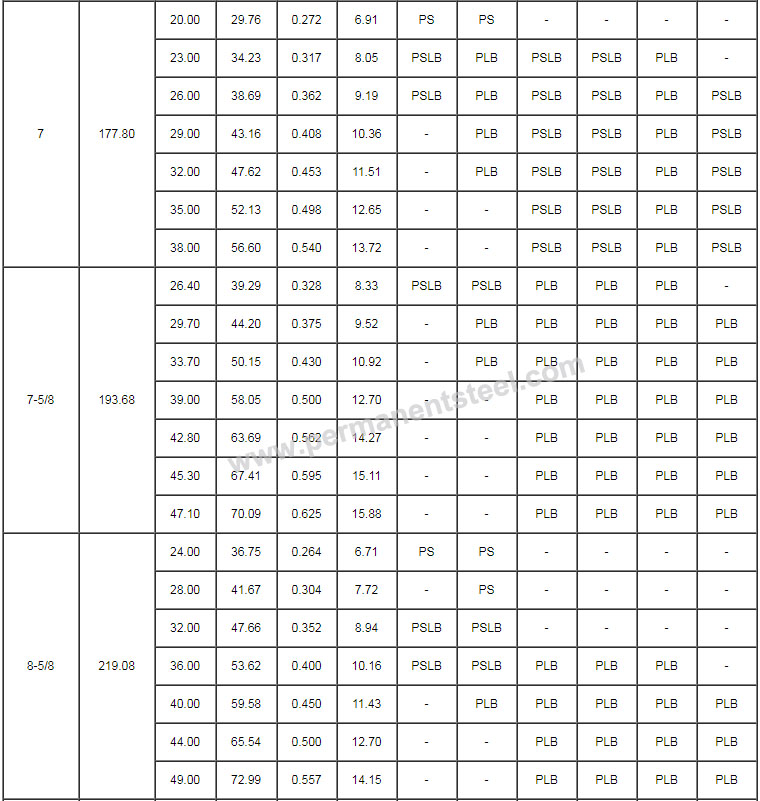

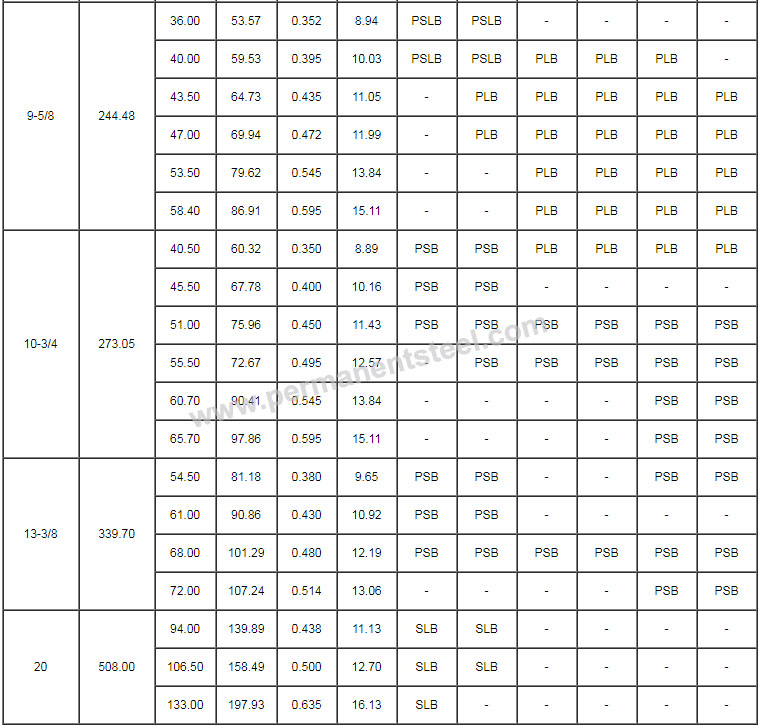

Technical specifications & sizes of Seamless Casing:

Casing Specification:

In utilizing seamless casing and connection, the purchaser and designer should follow the standards set by the American Petroleum Institute (API). The organization provides a variety of manufacturing standards for tubing and casing, which are also adopted by the International Standards Organization (ISO).

Casing specifications are usually presented in outer diameter (in or mm), nominal weight (lb/ft or kg/m), wall thickness (in or mm), and grade and connection type.

Outer Diameter

Outer diameter is usually fixed for a particular size.

Nominal Weight

The nominal weight presented in lb/ft or kg/m portrays the average linear weight of the seamless casing and connection, which limits the casing wall thickness that in turn defines the inner diameter.

Grade

The yield strength and material composition of the seamless casing are indicated by the grade of the casing.

Connection Type

The connection type shows the type of thread used to affix the oil well seamless casing joints. Premium connections can be defined as:

P – plain end

S – short round thread

B – buttress

L – long round thread

Permanent Steel Manufacturing Co., Ltd is a manufacturer of seamless casing and tubing in China. In the past two decades, we have been providing catering services for the oil and gas industry not only in China but also all over the world. Years of experience has provided us with expertise in manufacturing various special-purpose grades and pipes. Our skilled and experienced production team is capable of meeting any other requirements of customers and meeting tight schedules for supply of large projects. Our dedicated quality team is always eager to provide products that exceed the expectations of demanding customers. We are approved by API 5CT and most leading oil and gas companies.