Components of Oil Pipes

Oil tubing is a casing made of cast steel and usually consists of three main parts: casing pipe, drill pipe and derrick. Among them, the casing is the main component installed in the wellbore, and its function is to support the oil layer and protect the borehole wall; the drill pipe is used to drill through the rock and soil, and can also be used to lift and install the casing; the derrick is the component that supports the drill pipe so that it can rotate in the wellbore.

Composition of casing:

The casing is composed of a series of pipe sections, each pipe section has a threaded connector, and two adjacent pipe sections are connected by the same connection method. These tube sections are usually made of steel plate and reinforced by machining and coating treatments. At the lower end of the casing, there is also a subassembly usually called the "shoe", which prevents groundwater and other debris from entering the wellbore by sealing the bottom of the wellbore with cement or similar materials.

Drill pipe composition:

Drill pipe typically consists of a series of threaded steel pipes whose diameter and wall thickness typically vary with the depth of the well being drilled. The upper end of the drill pipe is connected to the drill pipe head of the drilling rig, which is used to transmit the torque of the drilling rig to the drill pipe, thereby driving the drill bit to rotate and pass through the rock and soil.

Derrick composition:

The derrick is the assembly that holds the drill pipe in place. It consists of a series of vertical steel pipes and transverse beams, stabilized by a ground support system. Derricks are capable of withstanding various forms of loads, such as horizontal and vertical loads and torques. Through this structure, the drill pipe can rotate, rise and fall in the well hole to complete the drilling operation. The derrick is a device used to place the crown block, suspend traveling blocks, hooks, lifting rings, elevators and other equipment during drilling or workover, as well as to hoist and store drill pipes, oil pipes and sucker rods.

The requirements for the derrick are:

1) There should be sufficient strength, stiffness and overall stability. To ensure that the drill pipe string, casing or tubing string can be lowered to a certain depth.

2) Sufficient working height and space, and sufficient drill floor area. The working height is large, the lifting length is long, and the speed is fast, which can save time. The upper and lower bottoms of the derrick should have the necessary dimensions to install the crane and ensure unimpeded movement of the traveling system equipment during hoisting and lowering operations; it is convenient to arrange equipment on the drill floor, place tools, facilitate workers' operations, and give the driller a good view.

3) It should be ensured that the disassembly and assembly are convenient, safe and can be moved quickly. To this end, the structure should be simple and light, and the installation and transportation methods of segmented or integral transportation, horizontal installation and integral lifting should be used as much as possible.

Structure of oil pipe:

1. OCTG pipe: It is the abbreviation of Oil Country Tubular Goods, including finished oil casing, drill pipe, drill collar, coupling, short connection, etc.

2. Oil pipe: pipes used in oil wells for oil recovery, gas recovery, water injection and acid fracturing.

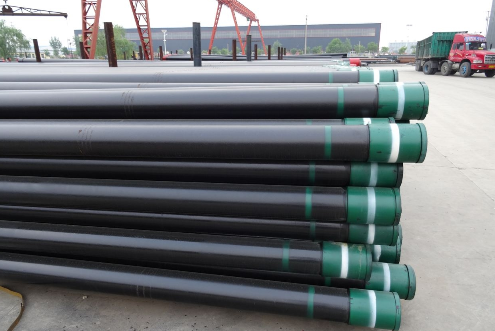

3. Casing: a pipe that is lowered from the ground surface into the drilled hole as a lining to prevent the wall from collapsing.

4. Drill pipe: a pipe used to drill a wellbore.

5. Line pipe: a pipe used to transport oil and gas.

6. Coupling: used to connect two threaded pipes and a cylindrical body with internal threads.

7. Coupling material: pipes used to make couplings.

8. API thread: pipe thread specified in API 5B standard, including oil pipe round thread, casing short round thread, casing long round thread, casing partial trapezoidal thread, line pipe thread, etc.

9. Special buckle: Non-API threaded buckle type with special sealing performance, connection performance and other properties.

Oil pipe is an important equipment in the petroleum industry, consisting of casing, drill pipe, derrick and other components. These components work together to enable operations such as drilling and oil production. Understanding these components and their functions is important in understanding the workings and mechanisms of the petroleum industry.