What is the Role of ERW Pipes in Different Industries?

What is the role of ERW pipes in different industries?

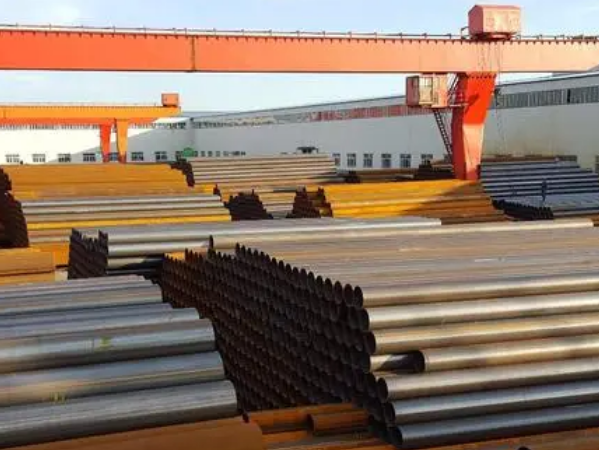

ERW Pipe & Tube means Electric Resistance Welded Pipe, which are a type of welded pipe manufactured through the process of rolling and welding the steel strip longitudinally. Their seamless flow and joint strength, created through electric current heating, make them versatile and cost-effective for various applications.

Multifunctional industry application areas of ERW pipes:

1) Oil and gas industry

1. Transporting oil and gas

ERW pipelines are critical for transporting oil and gas over long distances, ensuring safe and efficient distribution. They are used in oil and gas pipelines and help meet the world's growing energy needs.

2. Application in exploration and production

Their durability and corrosion resistance make them ideal for well casing pipe and conductors during exploration and production. ERW pipelines support the extraction of valuable resources from below the surface.

3. Corrosion-resistant and durable

ERW pipe offers excellent corrosion resistance, which is critical to maintaining pipe integrity. They help reduce maintenance costs and extend the life of oil and gas infrastructure.

4. Environmental and safety considerations

Using ERW piping can minimize leaks and spills, improving safety and reducing environmental risks. This contributes to sustainable energy practices and protects ecosystems.

2) Construction industry

1. Structural support and load-bearing applications

ERW pipes provide the necessary load-bearing capacity for building foundations and structural supports during construction. They form the backbone of tall buildings and critical infrastructure.

2. Water supply and sewage treatment system

Its smooth inner surface makes it ideal for water and wastewater systems to optimize water flow. ERW pipes ensure efficient water distribution and reliable wastewater management.

3. HVAC systems and industrial ducting

ERW ducting is suitable for HVAC systems and industrial piping because of its thermal conductivity and ease of installation. They play a vital role in maintaining a comfortable indoor environment.

Their fire resistance and durability are critical for fire protection and sprinkler systems. ERW ducts protect buildings and occupants and mitigate the effects of fire.

3) Mechanical and engineering applications

1. Machinery and equipment manufacturing

In machinery and equipment manufacturing, ERW pipes support the structural framework of various machines and appliances. They contribute to industrial productivity and economic growth.

2. Conveyor system

ERW pipes are used as conveyor frames for efficient material movement in the manufacturing and mining industries. They optimize production processes and logistics.

3. Structural applications of bridges and buildings

ERW pipes are vital in the construction of bridges and buildings, ensuring their stability and safety. They enable the development of modern infrastructure to meet the needs of growing urban populations.

4. Impact on the progress of mechanical engineering

The continued development and innovation in ERW tube manufacturing has greatly impacted the mechanical engineering industry. As new technologies and materials become available, mechanical engineers can design and build more efficient and sustainable machines and structures.

4) Automobile industry

1. Exhaust system and muffler

ERW pipes are used in exhaust systems and mufflers because of their resistance to high temperatures and exhaust gases. They ensure optimal engine performance and reduce emissions.

2. Chassis and frame manufacturing

In vehicle chassis and frame construction, ERW tubes provide structural strength and safety. They contribute to the car's overall stability and crashworthiness.

3. Fuel and hydraulic systems

ERW pipes ensure efficient fluid transfer in fuel and hydraulic systems. They are essential for the reliable operation of vehicle propulsion and braking systems.

4. Anti-collision and safety features

ERW tubes enhance vehicle crash resistance and safety. They protect passengers and reduce the severity of impacts during an accident.

5) Electrical industry

1. Electrical conduit and cable protection

ERW ducts house wires and cables to ensure safety in the electrical industry. They are critical to transmitting electricity safely and efficiently.

2. Underground power transmission

ERW conduits provide safe passage for underground power transmission, minimizing visual disturbance and ensuring reliable energy distribution.

3. Advantages over traditional wiring methods

ERW ducting increases the safety and reduces maintenance of electrical systems, supporting an increasingly electrified society.

4. Integration with renewable energy projects

The ERW pipeline supports the integration of renewable energy projects by providing reliable power infrastructure. They play a vital role in advancing clean energy plans.

6) Water supply and wastewater treatment

1. Water supply pipeline

ERW pipes form the backbone of water systems, ensuring the distribution of clean and potable water. They are critical to meeting the water needs of a growing population.

2. Sewage treatment system

In wastewater treatment, ERW pipes safely transport and discharge wastewater. Their corrosion resistance ensures efficient and environmentally friendly wastewater management.

3. Industrial water treatment applications

ERW pipe facilitates fluid transfer in industrial water treatment. They enable industries to meet strict environmental standards and recycle water for sustainable practices.

4. Advantages over other pipe materials

ERW pipe is cost-effective and lasts longer than other materials. Their recyclability further contributes to sustainable water management practices.

7) Agriculture and irrigation

1. Irrigation system

ERW pipes are widely used in irrigation systems to efficiently distribute water to crops. They play a key role in agricultural productivity and food security.

2. Agricultural water delivery

ERW pipelines facilitate water transport, reducing water wastage and ensuring water reaches remote farmlands.

3. Agricultural equipment and machinery

ERW pipes provide structural support for agricultural equipment and machinery, increasing their efficiency and reliability.

4. Longevity and cost-effectiveness in rural areas

The longevity and cost-effectiveness of ERW pipes make them the first choice for agriculture’s long-term water management needs. They can withstand harsh weather conditions, reducing maintenance costs for farmers.

8) Current challenges and limitations

1. Corrosion and degradation issues

Despite its corrosion resistance, ERW pipe may still be susceptible to corrosion in certain environments. Proper coating and maintenance are necessary to mitigate these problems.

2. Temperature and Pressure Limitations

Because ERW pipe has specific operating limitations, extreme temperature and pressure conditions require careful consideration.

3. Consideration of specific industry requirements

Choosing the right piping material is critical for a specific application, and engineers must consider industry-specific needs.

4. Ongoing research and development efforts

Ongoing research aims to enhance the future applications of ERW pipes and address the challenges they face. Innovations in materials and manufacturing techniques are continuing to improve their performance.

Conclusion:

ERW pipes are essential components in many industries, providing critical infrastructure and supporting economic growth. Future advances in ERW pipe performance may lead to further applications and improvements in existing industries. Encouraging sustainable practices in the use of ERW pipes, such as responsible manufacturing, proper maintenance and recycling will ensure a greener future and promote sustainable development. By adopting these practices, industries can reduce their environmental impact and support a more sustainable world. Continued innovation and adoption of ERW pipelines will play a vital role in addressing global challenges and promoting economic and environmental prosperity.

Read more: Price Comparison of Seamless Pipe and Welded Pipe