What is the Difference between Straight Seam Steel Pipe and SMLS Steel Pipe?

The difference of concepts:

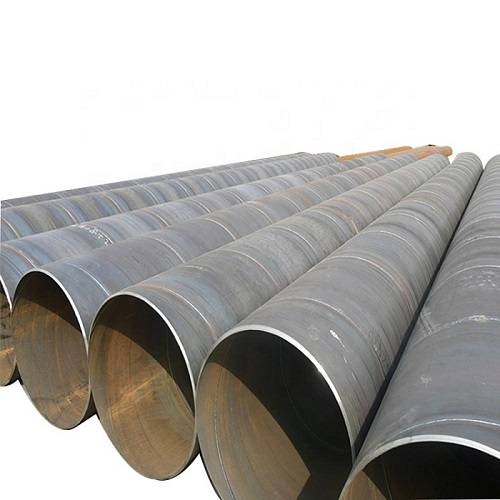

1. Straight seam steel pipe: Straight seam steel pipe is a steel pipe in which the weld seam is parallel to the longitudinal direction of the steel pipe.

2. SMLS steel pipe: a steel pipe made of a single piece of metal with no seams on the surface, called seamless steel pipe.

The difference of classifications:

1. Straight seam steel pipe: divided into metric electric welded steel pipe, electric welded thin wall pipe, transformer cooling oil pipe.

2. SMLS steel pipe: Seamless pipe is divided into hot-rolled pipe, cold-rolled pipe, cold-drawn pipe, extruded pipe, jacked pipe, etc. According to the cross-sectional shape, seamless steel pipes are divided into two types: round and special-shaped. Special-shaped pipes have square, oval, triangle, hexagonal, melon-shaped, star-shaped, and finned pipes in various complex shapes..

The difference of manufacturing process:

1. Straight Seam Steel Pipe: ERW (Electric Resistance Welding): Straight seam steel pipes are typically manufactured using ERW. In this process, a flat steel strip or coil is rolled into a cylindrical shape and the edges are welded together using electrical resistance.

LSAW (Longitudinal Submerged Arc Welding): Another method for making straight seam pipes is LSAW, where the edges are welded together using an arc welding process

2. SMLS Steel Pipe: Seamless steel pipes are manufactured through a process that involves piercing a solid billet of steel to create a hollow tube. This can be done using methods such as extrusion or rotary piercing.

The difference of applications:

1. Straight seam steel pipe: Straight seam steel pipe is mainly used in water supply projects, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction.

For liquid transportation: water supply and drainage. For gas transportation: coal gas, steam, liquefied petroleum gas. For structural purposes: piling pipes, bridges; pipes for docks, roads, building structures, etc.

2. SMLS steel pipe: Seamless steel pipe has a hollow section and is widely used as a pipeline for transporting fluids, such as pipelines for transporting oil, natural gas, coal gas, water and certain solid materials, etc. Compared with solid steel materials such as round steel, steel pipes are lighter in weight when the bending and torsion strength is the same, and they are an economical cross-section steel material.

It is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, bicycle frames, and steel scaffolding used in construction. Steel pipes are used to make ring parts.