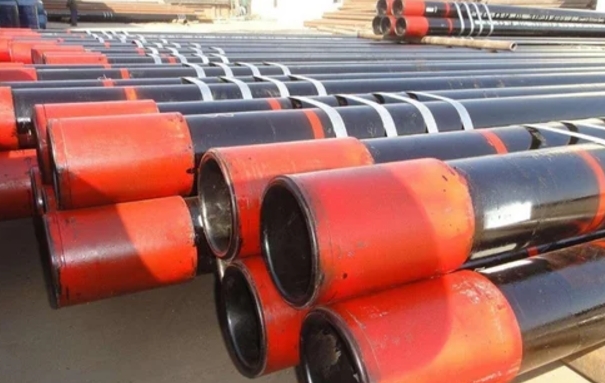

The Introduction of Large-diameter Oil Casing Pipes

The large-diameter oil casing pipe is a large steel pipe used in the process of oil and gas drilling and extraction to support the well wall, protect the wellbore, and provide a channel for underground operations. Its diameter is usually larger than that of general oil casing pipes and it can play a unique role in specific oil well conditions. Large-diameter oil casing pipes are made of both seamless steel pipes and welded steel pipes.

Specifications and dimensions of oil casing pipes

Diameter range: The diameter of large-diameter oil casing pipe is generally 13 3/8 inches (about 340 mm) and above. Other common specifications include 16 inches (about 406 mm), 18 5/8 inches (about 473 mm), and 20 inches (about 508 mm).

Wall thickness: Wall thickness is also an important factor affecting casing pipes performance, which is usually determined based on specific application requirements and the pressure it is subjected to. Generally speaking, the wall thickness of large-diameter casing pipes is also relatively thick to ensure that it has sufficient strength and support. For example, in high-pressure oil wells, the wall thickness may reach tens of millimeters.

Length: The length of a single casing pipe is generally around 9-12 meters. In actual applications, multiple casing pipes can be connected and used in combination according to the depth of the oil well and installation requirements.

Connection methods of oil casing pipes

1. Threaded connection: This is one of the more commonly used connection methods for large-diameter oil casing pipes. Special threads are machined on the ends of the casing pipes to screw the two casings pipes together. During the connection process, the threads need to be cleaned and thread grease applied to ensure the sealing and reliability of the connection. For large-diameter casing pipes, due to the high pressure it bears, higher requirements are placed on the processing accuracy of the threads and the tightening torque of the connection.

2. Welding connection: Welding connection has excellent sealing performance and can form a continuous whole, effectively preventing fluid leakage in the well, and has high connection strength and can withstand greater downhole pressure and external force. However, for large-diameter oil casing pipes, welding is relatively difficult and requires professional welding equipment, skilled welding personnel and strict quality control measures. Before welding, the casing pipe end needs to be processed by groove processing, cleaning and other preparatory work, and a comprehensive quality inspection is required after welding.

3. Special connection methods: Special methods such as expansion pipe connection can also be used to connect large-diameter oil casing pipes. These special connection methods are often developed for specific oil well conditions or technical requirements. They can play unique advantages in certain situations, but usually have a relatively narrow scope of application and high technical requirements.

Application Scenario of oil casing pipes

1. Oil well construction: In the early stage of oil well drilling, the large-diameter oil casing pipe is used as surface casing pipes to isolate the loose surface layer and establish the wellhead; when encountering complex formations during the drilling process, it is used as technical casing pipes to isolate the complex formations to ensure smooth drilling; in the oil and gas production stage, it is used as oil layer casing pipes to realize oil and gas production.

2. Oil wells with special working conditions: For deep-sea oil wells, large-diameter oil casing pipes need to have high strength and good corrosion resistance to cope with harsh working conditions such as high pressure, low temperature, and strong corrosion; For high-sulfur oil wells, excellent resistance to sulfur corrosion is required to prevent the casing pipes from being corroded and damaged, thereby ensuring the safety and sustainability of oil and gas extraction.

3. Oil well repair and reconstruction: When the casing pipe in the oil well is damaged, such as perforation, rupture, etc., large-diameter oil casing pipes can be used for repair; When an oil well needs to be side-drilled, large-diameter oil casing pipes will also play a role, such as first inserting a large-diameter casing pipes to partially block the original wellbore, and then performing side-drilling operations from the casing pipes.