Introduction of Thick-walled Stainless Steel Seamless Pipes

Definition and Specifications

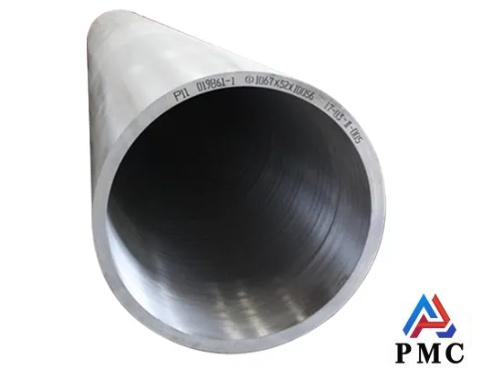

Definition: Thick-walled stainless steel seamless pipe is a stainless steel pipe with a relatively high wall thickness. It is made of steel ingots or solid tubes through perforation into rough tubes, and then made through hot rolling, cold rolling or cold drawing. It has no seams around it and is a type of stainless steel pipe.

Specification range: The outer diameter of large-diameter thick-walled stainless steel seamless pipes is usually more than 325mm, and the wall thickness is more than 20mm. Currently, the single weld diameter can reach 1220mm, the wall thickness can reach 80mm, and the double weld diameter can reach 2020mm.

What are the characteristics of thick-walled stainless steel seamless pipes?

1. High corrosion resistance: Thick-walled stainless steel seamless pipes have excellent corrosion resistance and can resist the erosion of various chemical substances, thus ensuring their long service life.

2. High strength: Thick-walled stainless steel seamless pipes have high strength and hardness and can withstand large loads and pressures, so they are suitable for various occasions that require high-strength support.

3. Thin wall: The thick-walled stainless steel seamless pipe has a thinner wall, which makes it light and flexible, easy to install and use.

4. Seamless: Thick-walled stainless steel seamless pipes are made by stretching the entire metal at one time, so each pipe head is polished to ensure a beautiful appearance.

5. Easy to bend: Thick-walled stainless steel seamless pipes have good flexibility and plasticity, can be bent and deformed, and are suitable for making various curved shapes and structures.

6. Safety: Thick-walled stainless steel seamless pipes will not produce harmful substances at high temperatures. They are safe and reliable and are suitable for various occasions that require high safety.

7. Hygiene and environmental protection: Thick-walled stainless steel seamless pipes are hygienic and environmentally friendly, will not breed bacteria, meet the requirements of hygiene and environmental protection, and are suitable for pipeline systems in the fields of drinking water, food processing, etc.

8. Beautiful and durable: The surface of thick-walled stainless steel seamless pipe is smooth and beautiful, not easy to rust, can maintain its original color for a long time, and extend its service life.

9. Wide range of applications: Thick-walled stainless steel seamless pipes are suitable for pipeline systems in various industries and fields, such as construction, machinery, petrochemicals, medical equipment, etc.

10. High cost performance: Thick-walled stainless steel seamless pipes have high cost performance. Although the price is relatively high, they have a long service life and low maintenance costs. Overall, they have a high cost performance.

Thick-walled stainless steel seamless pipe application areas

1. Large steel structure construction: such as bridge piling, seabed piling, high-rise building piling, etc., can be used as the main support part because it can withstand large loads and pressures.

2. Petrochemical industry: used to transport corrosive media such as oil, natural gas, chemical products, etc., with good corrosion resistance and pressure resistance.

3. Nuclear energy field: In the construction and operation of nuclear power plants, it can be used to manufacture nuclear reactor components, piping systems, etc., meeting strict safety and quality requirements.

4. Mechanical manufacturing: It can be used to manufacture parts of various mechanical equipment, such as hydraulic cylinders, piston rods, transmission shafts, etc., providing high strength and wear resistance.

5. Aerospace: Used in structural components and piping systems of aircraft and spacecraft, with high strength, lightweight and corrosion resistance.

6. Food processing industry: Pipes used in food production and processing equipment to ensure the hygiene and safety of food, while being able to resist corrosion from chemical substances during food processing.

7. Pharmaceutical industry: It can be used to manufacture pipes and components in medical devices and pharmaceutical equipment, meeting strict hygiene standards and corrosion resistance requirements.

8. High-pressure pipeline systems: such as steam pipelines, high-pressure gas transmission pipelines, etc., which can withstand high pressure and maintain sealing performance.

9. Marine engineering: It has good corrosion resistance in the marine environment and can be used for pipelines and structural parts of offshore platforms and marine ships.

10. Thermal engineering: Pipeline systems used to transport high-temperature media, such as steam-water pipelines in thermal power plants.