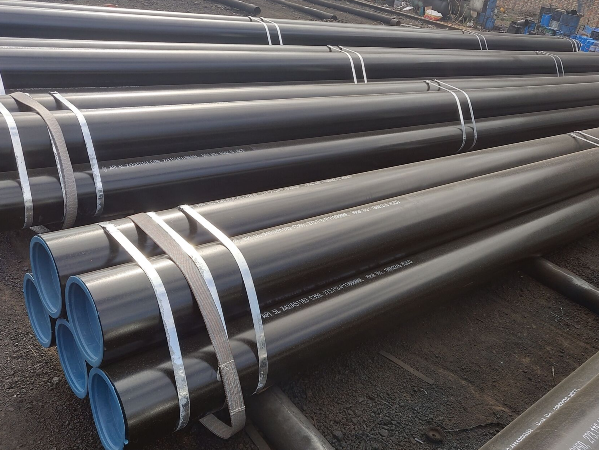

The Application of Seamless Steel Pipes in Various Industries

Seamless steel pipe (smls pipe) is a kind of pipe with excellent properties such as high strength, corrosion resistance and high temperature resistance. It is widely used in petroleum, natural gas, chemical industry, machinery and other industries. This article will focus on the application of seamless steel pipes in petroleum, natural gas, chemical, machinery and other industries, analyze its advantages and disadvantages, and discuss future development directions.

1. Application of seamless steel pipes in oil and natural gas industries

The oil and natural gas industry is one of the important areas where seamless steel pipes are used. Due to the harsh environment of oil and natural gas mining, pipes are required to have high strength, corrosion resistance, high temperature resistance and other properties. Due to its excellent performance, seamless steel pipes have gradually replaced traditional welded steel pipes and become the preferred pipe material for long-distance oil and natural gas pipelines.

In the oil and natural gas industry, seamless steel pipes are mainly used in oil and gas field surface construction, oil and gas transmission pipelines, wellbore pipes, etc. Its advantages are: high strength and toughness, able to withstand extreme pressure and temperature; excellent corrosion resistance, able to adapt to various complex oil and gas field environments; reliable connection, ensuring safe operation of pipelines.

However, the application of seamless steel pipes in the oil and gas industry also has some shortcomings. For example, production costs are high and advanced production processes and technologies are required; at the same time, due to the large mass of seamless steel pipes, transportation and installation costs are also relatively high.

2. Application of seamless steel pipes in chemical industry

The chemical industry is another important application area. In chemical production, the materials transported by pipelines are usually highly corrosive, toxic, or flammable and explosive, requiring pipes with high strength, corrosion resistance and other properties.

Seamless steel pipes are mainly used in the chemical industry for transportation pipelines, reactor supports, chimneys, etc. Its advantages are: excellent corrosion resistance, able to adapt to various corrosive media such as strong acids and strong alkali; high strength, able to withstand the pressure inside the pipeline and external gravity; reliable connection, which can ensure the safe operation of the pipeline.

However, the application of seamless steel pipes in the chemical industry also has some disadvantages. For example, production costs are high and advanced production processes and technologies are required; at the same time, due to the large mass of seamless steel pipes, transportation and installation costs are also relatively high.

3. Application of seamless steel pipes in the machinery industry

The machinery industry is another important area for seamless steel pipe applications. In machinery manufacturing, pipes are mainly used to manufacture various mechanical parts, such as oil cylinders, gas bottles, pressure vessels, etc.

Seamless steel pipes are mainly used in the machinery industry to manufacture high-precision mechanical components and equipment. Its advantages are: high precision and high strength, which can meet the requirements of high-precision mechanical components; excellent corrosion resistance, able to adapt to various complex working environments; reliable connection, which can ensure the safe operation of mechanical components.

However, the application of seamless steel pipes in the machinery industry also has some shortcomings. For example, production costs are high and advanced production processes and technologies are required; at the same time, due to the large mass of seamless steel pipes, transportation and installation costs are also relatively high.

Future direction:

With the continuous advancement of technology and increasing application requirements, seamless steel pipes will continue to play an important role in the future. Future development directions include: improving production efficiency and reducing production costs; developing new materials and processes to improve the performance and quality of seamless steel pipes; expanding application fields and exploring new application scenarios and uses.

Conclusion:

As a high-performance pipe, seamless steel pipe has been widely used in petroleum, natural gas, chemical industry, machinery and other industries. Its excellent performance and high reliability provide strong support for the development of various industries. In the future, with the continuous advancement of technology and the increasing demand for applications, it is believed that the application prospects of seamless steel pipes will be even broader.

Read more: Seamless vs Welded Pipe