Structural Application of Cold Rolled Seamless Steel Pipes

Characteristics of cold rolled seamless steel pipe

High-precision cold-drawn precision steel pipe is a new type of steel pipe, its main feature is high precision. There are usually two production processes: two-roll mill and three-roll mill. The precision of three-roll mill to produce cold-rolled smls steel pipes is higher and can be controlled within a few wires, but the price is relatively higher.

The promotion and application of high-precision cold-drawn precision steel pipes will save steel, improve processing efficiency, and save energy. The so-called high-precision cold-drawn seamless steel pipe refers to the strict dimensional accuracy (tolerance range) of the inner and outer diameters, and the good internal and external surface finish, roundness, and straightness, which can greatly save machining hours, improve material utilization, and at the same time help improve the product quality.

Technological process of cold rolled seamless steel pipe

The main advantage of cold rolled steel pipe is that the section reduction rate is large, especially the wall reduction ability is strong. For carbon steel, the section reduction rate of a rolling can reach 80% to 83%, and alloy steel can reach 72% to 75%. The main disadvantage is the difficulty of tool replacement. In addition to being directly used to produce some cold-rolled pipes with higher precision, the cold rolling method is often used in conjunction with the cold drawing method to create blanks for cold drawing. This can not only give full play to the wall-reducing ability of cold rolling, but also cleverly utilize the advantages of easy replacement of cold drawing tools, which is conducive to improving productivity, expanding product production range and improving steel pipe surface quality.

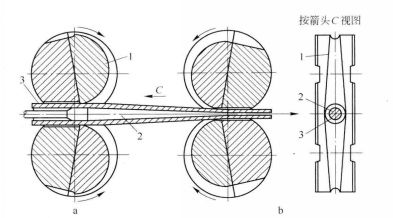

Cold-rolled pipe production uses periodic cold-rolled pipe machines. The working characteristic of the periodic cold-rolled pipe mill is that the steel pipe and the mandrel do not move, and the reciprocating motion of the frame drives the rolling of the steel pipe, and the variable cross-section profile is used to compress the rolled piece to achieve the purpose of diameter and wall reduction.

When the rolling mill and roll are in the original position a, the pass size is the largest (slightly larger than the outer diameter of the billet); When reaching the stroke limit position b, the hole pattern is slightly larger than the outer diameter of the finished product; Before reaching the b position, the hole size is the smallest, which is equal to the outer diameter of the finished product;

At the original position a, the pipe material is fed. Depending on the size of the rolling mill, the pipe material is fed 3 to 30 mm each time. At position b, turn the pipe material over, 60° to 90° each time, so that the roller can flatten the pipe wall when it returns. After returning to the original position a, the pipe material is fed in to start the next cycle of rolling. The pipe material is rolled repeatedly in this way, and finally the cold-rolled steel pipe of the required size is rolled out.

Structural of cold-rolled seamless steel pipes

Cold-rolled seamless steel pipe, as a high-quality seamless steel pipe, is characterized by high dimensional accuracy and excellent surface finish, which makes it ideal for use in structural applications that require precision dimensions and smooth surfaces. Specifically,the application fields of cold-rolled seamless steel pipe include:

1. Precision mechanical structure: In precision machinery,the dimensional accuracy and surface finish of components are crucial to the performance and life of the entire machinery. Cold-rolled smls pipe are able to meet the stringent requirements of precision mechanical structures due to their high precision and smooth surface.

2. Hydraulic equipment: Pipes and connections in hydraulic equipment need to have good sealing and pressure resistance. Because of its excellent physical properties, cold-rolled seamless steel pipes can meet these needs of hydraulic equipment and ensure the stable operation of the system.

3. Reinforcement sleeve: In the field of construction,The quality of steel sleeves directly affects the stability and safety of the building structure. Cold rolled seamless steel pipe for its high precision and excellent surface finish is suitable for making steel bar sleeve so as to improve the overall quality of building structure.

In order to ensure the quality and performance of cold-rolled seamless steel pipes, visual inspection, dimensional measurement, non-destructive testing and other means will be used during the production process to ensure that they comply with relevant standards and requirements. Unqualified steel pipes will be processed and replaced in a timely manner to ensure the effectiveness and safety of use. Therefore, understanding the functions and uses of cold-rolled seamless steel pipes, making processes and precautions is of great significance for the correct use and maintenance of this important metal material