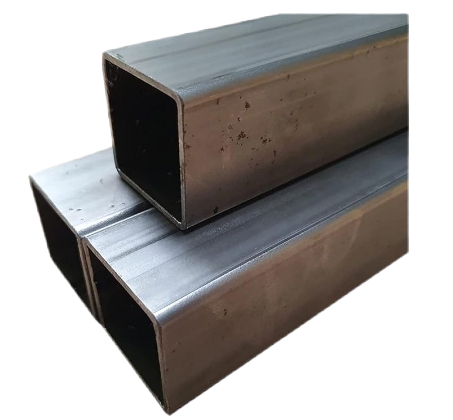

Application of Seamless Square Steel Tube

Seamless square steel tube is a square steel tube with four corners. It is a square steel tube formed by cold drawing and extrusion of seamless steel tube. There is an essential difference between seamless square tube and welded square tube. Steel pipes have hollow sections and are widely used as pipes for transporting fluids.

Basic Introduction of Seamless Square Steel Tubes

Compared with solid steel materials such as round steel, steel pipes are generally lighter in weight when the bending and torsional strength is the same. It is an economical cross-section steel and is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, etc.

Steel pipes and round steel are used in bicycle racks and steel scaffolding that used in construction, etc. Ring parts which are made from steel pipes can improve material utilization, simplify manufacturing processes, and save materials and processing time, such as rolling bearing rings, jack sleeves, etc. Steel pipes are also an indispensable material for various conventional weapons and military machinery. Gun barrels, barrels, etc. are all made of steel pipes. Steel pipes can be divided into round pipes and special-shaped pipes according to different cross-sectional area shapes. Because under the condition of equal circumference, circular pipes can transport more fluids.

When the circular cross-section is subjected to internal or external radial pressure, the force is relatively uniform. The vast majority of steel pipes are round pipes.

Main Properties of Seamless Steel Pipe

1. Plasticity

Plasticity refers to the ability of a metal material to produce plastic deformation (permanent deformation) without destruction under load.

2. Hardness

Hardness is a measure of how hard or soft a metal material is. The most commonly used method for measuring hardness in this production is the indentation hardness method. It uses an indenter of a certain geometric shape to press into the surface of the metal material being tested under a certain load, and its hardness value is measured based on the degree of intrusion.

The commonly used methods include Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV).

3. Fatigue

Strength, plasticity, and hardness are all mechanical performance indicators of metal under static load. In fact, many machine parts are operated under cyclic loading, and fatigue will occur in the parts under such conditions.

General Uses of Seamless Square Steel Tubes

1. Structural seamless steel pipe (GB/T8162-1999) is a seamless steel pipe which used for general structures and mechanical structures.

2. Seamless steel pipes for fluid transportation (GB/T8163-1999) are general seamless steel pipes which used to transport fluids such as water, oil, and gas.

3. Seamless steel pipe for petroleum cracking (GB9948-88) is a seamless steel pipe suitable for furnace tubes, heat exchangers and pipelines in petroleum refineries.

4. Steel pipes for geological drilling (YB235-70) are steel pipes used by geological departments for core drilling. According to their uses, they can be divided into drill pipes, drill collars, core pipes, casings and sedimentation pipes, etc.

5. Seamless steel pipe for diamond core drilling (GB3423-82) is a seamless steel pipe used for drill pipe, core rod and casing for diamond core drilling.

6. High-pressure oil pipe for diesel engines (GB3093-2002) is a cold-drawn seamless steel pipe used to manufacture high-pressure pipes for diesel engine injection systems.

7. Special-shaped seamless steel pipe is a general term for seamless steel pipes with other cross-sectional shapes other than round pipes.

Read more: The Difference Between Welded Square Tube and Seamless Square Tube