Stainless Steel Tube Bender

Date:2017-09-28 keywords:stainless steel tube bender, bender

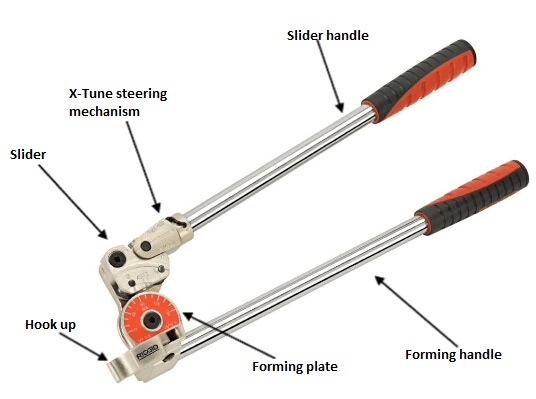

Stainless steel tube bender is usually used to the tool is RIDGID 600 series heavy load bender, the following steps and the use:

1. Stainless steel tube bener operation

1. Hold the bend tube forming handle or secure the bender to the vise.

2. Release the hook and lift the slider handle.

3. Place the pipe in the forming slot and secure it in the forming disc with a hook.

4. Lower the slider handle until the "0" scale on the hook aligns with the 0 ° position on the forming disc.

5. Rotate the slider handle around the forming disc until the "0" scale on the slider aligns with the desired amount on the forming disc.

2. 90 °to 180 °bending

1. When the pipe has been bent to 90 °, turn the slider handle to unlock the X-Tune steering mechanism.

2. Raise the slider handle around the slider until the 90-180 °triangle mark is aligned with the triangular mark on the hook.

3. Rotate the slider handle to adjust the X-Tune steering mechanism to the locked position.

4. Operate the slider handle to continue with the bender until the "0" line on the slider aligns with the desired bending angle. (Two handles will not cross).

3. Accurate bender (bending after measurement) against other target points (pipe ends, bending points, etc.)

1.90 °bending:

The mark is marked on the pipe according to the distance (X) required from the target point (pipe end, bending point, etc.). The distance is the bend from the center of the corner to the target point.

Place the pipe in the bend pipe.

If the target point is to the left of the mark, align the mark on the fitting with the "L" line on the hook.

If the target point is to the right of the mark, align the mark on the fitting with the "R" line on the hook.

4. 45 ° bending:

The mark is marked on the pipe according to the distance (X) required from the target point (pipe end, bending point, etc.). The distance is the arc

The distance from the center of the segment to the target point.

Place the pipe in the bend pipe.

Align the mark on the pipe with the 45 °line on the slider

After aligning the markings on the fitting, move the hook so that the "0" line is aligned with the 45-degree line on the dial.

5. Rebound

All the material of the pipeline in the completion of the pipe after the operation will have a certain amount of rebound. Soft material pipes (such as brass) than hard materials (such as stainless steel pipe) rebound less. Therefore, according to experience, it is recommended in the bender to retain a certain degree of pipeline rebound compensation, usually 1 ° ~ 3 ° or so, depending on the specific pipe material and hardness.

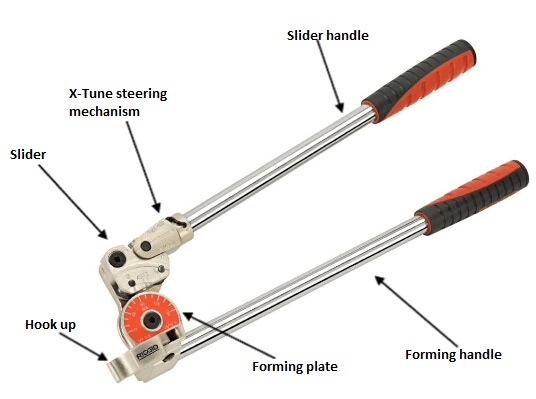

1. Stainless steel tube bener operation

1. Hold the bend tube forming handle or secure the bender to the vise.

2. Release the hook and lift the slider handle.

3. Place the pipe in the forming slot and secure it in the forming disc with a hook.

4. Lower the slider handle until the "0" scale on the hook aligns with the 0 ° position on the forming disc.

5. Rotate the slider handle around the forming disc until the "0" scale on the slider aligns with the desired amount on the forming disc.

2. 90 °to 180 °bending

1. When the pipe has been bent to 90 °, turn the slider handle to unlock the X-Tune steering mechanism.

2. Raise the slider handle around the slider until the 90-180 °triangle mark is aligned with the triangular mark on the hook.

3. Rotate the slider handle to adjust the X-Tune steering mechanism to the locked position.

4. Operate the slider handle to continue with the bender until the "0" line on the slider aligns with the desired bending angle. (Two handles will not cross).

3. Accurate bender (bending after measurement) against other target points (pipe ends, bending points, etc.)

1.90 °bending:

The mark is marked on the pipe according to the distance (X) required from the target point (pipe end, bending point, etc.). The distance is the bend from the center of the corner to the target point.

Place the pipe in the bend pipe.

If the target point is to the left of the mark, align the mark on the fitting with the "L" line on the hook.

If the target point is to the right of the mark, align the mark on the fitting with the "R" line on the hook.

4. 45 ° bending:

The mark is marked on the pipe according to the distance (X) required from the target point (pipe end, bending point, etc.). The distance is the arc

The distance from the center of the segment to the target point.

Place the pipe in the bend pipe.

Align the mark on the pipe with the 45 °line on the slider

After aligning the markings on the fitting, move the hook so that the "0" line is aligned with the 45-degree line on the dial.

5. Rebound

All the material of the pipeline in the completion of the pipe after the operation will have a certain amount of rebound. Soft material pipes (such as brass) than hard materials (such as stainless steel pipe) rebound less. Therefore, according to experience, it is recommended in the bender to retain a certain degree of pipeline rebound compensation, usually 1 ° ~ 3 ° or so, depending on the specific pipe material and hardness.

- 【Prev】 : Austenitic Stainless Steel Solution Treatment

- 【Next】 : Stainless Steel Tube Cutter

News Update :

Do Seamless Steel Pipes Need Galvanizing?...

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy