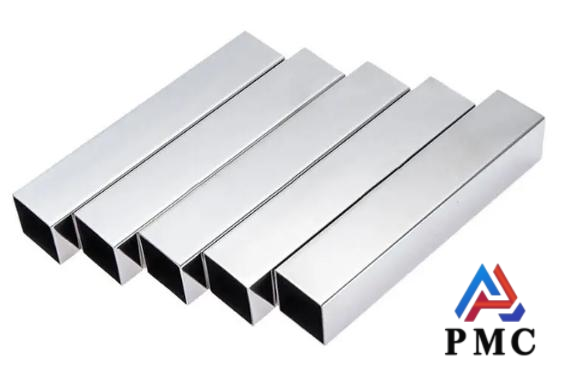

Seamless Rectangular Tubes: the best Choice for Engineering

Seamless rectangular tube is a kind of tube with rectangular cross section, which is made by seamless process. Compared with seamed tube, its biggest feature is that there is no weld around the tube body, which makes the tube more superior in overall performance. From the root of the manufacturing process and the seamless characteristics, seamless rectangular tubes belong to seamless tubes. In the field of modern engineering, the demand for high-quality and high-performance pipes is growing. As a unique pipe, the seamless rectangular pipe is gradually becoming the preferred material in the engineering industry due to its excellent performance and wide application.

Characteristics of seamless rectangular tubes

Seamless rectangular tubes, as the name implies, have a rectangular cross-section and the entire tube body have no welding or connection points. This property makes seamless rectangular tubes excellent in structural strength, sealing and durability. Due to its special manufacturing process, the seamless rectangular tube has the characteristics of high precision and high flatness, and can meet various high-standard engineering requirements.

Application of seamless rectangular tubes

Seamless rectangular tubes are widely used in various engineering fields, such as construction, chemical industry, petroleum, electric power, etc. In the construction field, seamless rectangular tubes are used as structural supports and fluid delivery pipes. Their high strength and good sealing performance ensure the safety and stability of buildings. In the chemical and petroleum fields, seamless rectangular tubes are used to manufacture key equipment such as pipeline systems and reactor supports due to their corrosion resistance and high pressure resistance. In the field of electric power, seamless rectangular tubes are used to manufacture cable supports, transformer coil frames, etc. Their excellent conductivity ensures the stability and safety of power transmission.

Advantages of seamless rectangular tubes

Compared with traditional welded pipes, seamless rectangular pipes have the following significant advantages:

High structural strength: Since there are no welding points in the entire tube body of the seamless rectangular tube, its structural strength is much higher than that of welded pipes. This makes it excel in high-stress, high-load engineering environments.

Good sealing performance: The seamless rectangular tube has excellent sealing performance, which can effectively prevent fluid leakage and ensure the safety and stability of fluid transportation.

Strong corrosion resistance: The seamless rectangular tube has been specially treated to have good corrosion resistance and can adapt to various complex environmental conditions.

Long service life: Due to its excellent structural and chemical properties, seamless rectangular tubes have a long service life, reducing the cost of frequent replacement and repairs.

Conclusion

In summary, seamless rectangular tubes have become the preferred material in the engineering field due to their excellent performance and wide application. Its emergence has provided reliable support and guarantee for various engineering projects and promoted the sustainable development of the engineering industry.With the advancement of technology and the continuous growth of application needs, I believe that seamless rectangular tubes will continue to play an important role in the future and contribute more value to engineering construction.

Read more: The Application of Seamless Square and Rectangular Tube