Oil and Gas Well Wire Wound Screen

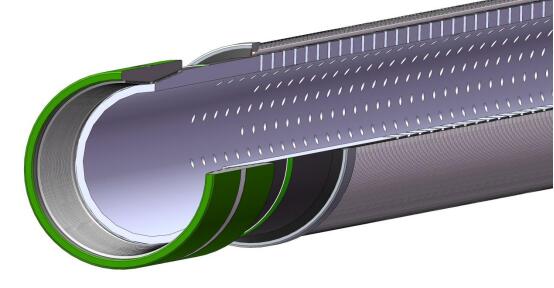

Wire-wound screens for oil and gas wells are composed of drilled base pipes, filter sleeves and end rings. The base pipe is a petroleum oil casing pipe that conforms to API specifications; the filter sleeve is formed by using trapezoidal wire, triangular wire or special-shaped winding wire and welding it on a group of supporting wires (ribs) arranged in a circular pattern through special equipment. The welding of wire wrapping and supporting ribs is a whole-process welding, which ensures the strict continuous integrity of the product, makes it form a controllable and precise gap size, and has the performance to withstand high pressure in the largest amount. It is widely used in petroleum, papermaking, chemical industry, natural gas, food, beer, water well sand control and other industries.

Product features of wire wound screen for oil and gas wells:

1. The small surface and the large gap opening below make the gap self-cleaning, which ensures the smoothness of fluid filtration, and provides a guarantee for improving production efficiency and extending the service life of the filter.

2. The winding wire and all supporting ribs are fully connected by electric welding, which is durable and has a longer working life cycle.

3. The minimum width of the opening gap reaches 0.1mm, which can meet the needs of most sand control work, with the same filtration accuracy and higher flow area.

4. Different specifications and raw materials (mainly stainless steel and carbon steel) can be customized according to the actual needs of customers, so as to ensure reasonable investment and save production costs; non-stainless steel products can be galvanized to form a protective layer, and the appearance is beautiful and clean.

We provide base pipe of screen in many options of size and pipe joints (thread or coupling) accordance to API standard. Our screen available in tailor made need.

Sand control screen positioned in the wellbore serve to block out sand while allowing the flow through of oil or water. Our screens giving precise particle size control compare to slotted pipe while maintaning the same high strength and durability, excellent corrosion resistance, high pressure tolerance.

Sand screen using bigger hole of slotted pipe wrapped with our screens will increased containment capacity, production capacity and excellent backwash efficiency.