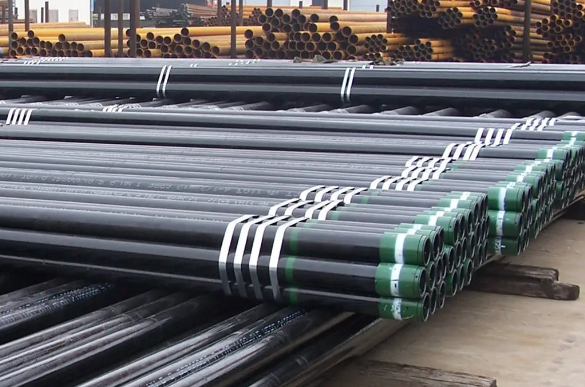

Introduction to Oil Casing Pipe J55 N80 P110

First, let’s look at J55 oil casing pipe.

The "J55" in the name of this casing represents its tensile strength of 55,000 psi, which shows its high strength. During the oil drilling process, J55 oil casing can effectively support the well wall, prevent the well wall from collapsing, and ensure the safety of drilling operations. At the same time, its good plasticity enables the casing to adapt to various complex underground environments and provide stable support for drilling operations. In addition, J55 oil casing also has high corrosion resistance and processability, and can be used for a long time in harsh underground environments without being easily damaged, reducing maintenance costs and improving drilling efficiency.

Next, let’s look at N80 oil casing pipe.

N80 casing pipe occupies its place in the field of oil drilling due to its excellent strength and toughness. It can not only withstand huge underground pressure, but also resist various corrosion and wear, ensuring the smooth progress of drilling operations. In addition, N80 oil casing also has good welding performance and sealing performance, and can work closely with other equipment to ensure the stable operation of the entire drilling system.

Finally, let’s take a look at P110 oil casing pipe.

P110 casing pipe is famous for its high strength and toughness, and is suitable for drilling operations in complex geological conditions such as deep wells and ultra-deep wells. It can not only withstand extremely high underground temperatures and pressures, but also resist various harsh geological environments, ensuring the safety and efficiency of drilling operations. In addition, P110 oil casing also has good fatigue resistance and wear resistance, which can maintain stable performance for a long time and reduce drilling costs.

In the selection process of oil casing pipe, we need to select the appropriate model based on specific drilling conditions and needs. For shallow and medium-depth wells, J55 oil casing is usually a good choice because of its sufficient strength and relatively low cost. For deep and ultra-deep wells, or areas with particularly complex geological conditions, we may need to choose higher strength N80 or P110 oil casing to ensure the safety and efficiency of drilling operations.

In addition, we also need to pay attention to the quality of oil casing pipe. High-quality OCTG casing pipe should have uniform wall thickness, smooth inner and outer walls, and good welding and sealing properties. During use, we need to regularly check the integrity of the casing and promptly discover and deal with possible problems to ensure the smooth progress of drilling operations.

Read more: What are the Grades of OCTG Casing Material?