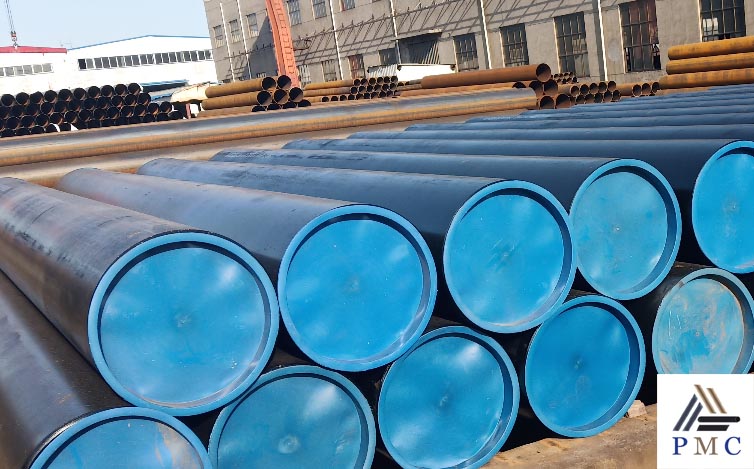

How to Paint Carbon Steel Tubes?

Carbon steel tubes consist of an iron and carbon alloy that is able to be bent into shapes during manufacture without reducing its high tensile strength. It is important to protect the steel surface from corrosion due to the iron ferrite composition that will rust through oxidization from water contact. The pipework that supplies fire sprinkler systems is often carbon steel, and requisite strength components such as cam and crank shafts in aircraft and cars use carbon steel tubes and tubing. Painting carbon steel tubes to effectively avoid corrosion requires the use of the correct primer and paint.

How to Paint Carbon Steel Tubes?

1. Use wire wool and remove all surface rust from the carbon steel tube. Sweep up any rust particles using a hand brush to keep the work area clear of dust.

2. Use a solvent-based cleaner and a cloth to scrub off all grease and oil stains from the surface of the pipe. Wipe the cloth over the entire surface of the pipe to collect any dust or rust particles that remain. Allow the carbon steel to dry.

4. Load the primer onto a paintbrush and apply a thick coat to the carbon steel pipe. Allow the primer to dry according to the manufacturer's instructions.

6. Allow the first coat of paint to dry according to the manufacturer's instructions. Generally, most acrylic paint is ready for a following coat after two hours. Paint a final coat of polyurethane acrylic over the surface of the carbon steel pipe to complete the task.

Due to the needs of the industry, the api carbon seamless pipe should not only pay attention to the smooth and bright surface, but also pay attention to the protection of the interior. Therefore, in the process of painting, the corresponding quality inspection should be carried out, and the time should be properly controlled.

Carbon steel pipe painting has the following main functions:

1. Anti-corrosion: Isolate corrosive media such as oxygen, moisture, and salt spray, and extend service life through physical barriers and chemical corrosion inhibition (such as sacrificial anode protection of zinc-rich primer).

2. Wear and impact resistance: Thick slurry coating improves surface hardness, resists mechanical collision and fluid erosion, and is suitable for wear scenarios such as mining and chemical industry.

3. Functional adaptation: High-temperature resistant coatings (such as silicone) are suitable for thermal pipes; thermal insulation coatings control surface temperature to meet energy-saving needs.

4. Safety signs: Use colors to distinguish media (such as red for steam, yellow for gas) or warn of dangers (such as yellow and black to prevent collision) according to industry standards to reduce the risk of misoperation.

5. Aesthetic maintenance: Provide a unified appearance, reduce the cost of later maintenance such as rust removal and repair welding, and improve the overall texture of the project.