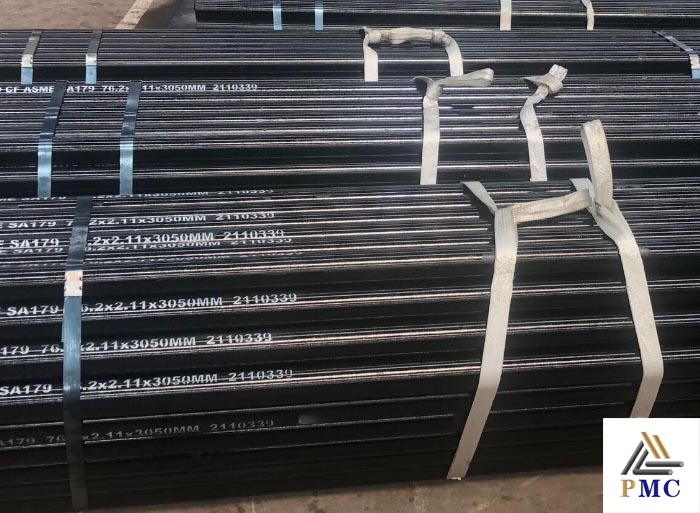

High-pressure Boiler Seamless Steel Pipe, Seamless Boiler Tube

High-pressure boiler seamless steel tubes are often under high temperature and pressure when used. The tubes will be oxidized and corroded under the action of high temperature flue gas and water vapor. It is required that the steel pipe has high durability, high resistance to oxidation and corrosion, and good structural stability. High-pressure boiler seamless tubes are mainly used to manufacture superheater tubes, reheater tubes, air ducts, and main steam tubes for high-pressure and ultra-high-pressure boilers.

Low and medium pressure boiler tubes GB3087-2008, seamless steel tubes for high pressure boilers GB5310-1995 are used to manufacture low temperature and high pressure boiler superheated steam pipes, boiling water pipes and locomotive boiler superheated steam pipes, large smoke pipes, small smoke pipes Hot-rolled and cold-drawn (rolled) seamless steel tubes of high-quality carbon structural steel for arch brick pipes. Structural seamless steel tubes (GB / T8162-2008) are seamless steel tubes for general and mechanical structures.

Specifications and appearance quality: GB5310-95 "Seamless Steel Tubes for High Pressure Boilers" The outer diameter of hot-rolled tubes is 22 to 530mm, and the wall thickness ranges from 20 to 70mm. Cold-drawn (cold-rolled) pipe has an outer diameter of 10 to 108 mm and a wall thickness of 2.0 to 13.0 mm.

The special-shaped seamless steel pipe is a general term for seamless steel pipes of other cross-sectional shapes other than round pipes. According to the different shapes and sizes of the steel pipe section, it can be divided into equal-wall thickness shaped seamless steel pipes (code D), unequal-wall thickness shaped seamless steel pipes (code BD), and variable-diameter shaped seamless steel pipes (code BJ). Shaped seamless steel tubes are widely used in various structural parts, tools and mechanical parts. Compared with the round pipe, the special-shaped pipe generally has a larger moment of inertia and a section modulus, and has a greater resistance to bending and torsion, which can greatly reduce the structural weight and save steel.

Production method of boiler seamless tube

Boiler seamless tube is a kind of seamless tube. The manufacturing method is the same as that of seamless pipes, but there are strict requirements on the steel grades used in the manufacture of steel pipes. According to the operating temperature, it can be divided into general boiler tubes and high-pressure boiler tubes.

(1) Manufacturing method:

① Generally, the service temperature of boiler seamless pipe is below 450℃. Domestic pipes are mainly made of No. 10 and No. 20 carbon steel hot-rolled pipes or cold-drawn pipes.

②High-pressure boiler tubes are often in high temperature and high pressure conditions when they are used. The tubes will be oxidized and corroded under the action of high-temperature flue gas and water vapor. The steel pipe is required to have high enduring strength, high oxidation and corrosion resistance, and good organizational stability.

Seamless steel tube production process:

The production processes of seamless steel tubes mainly include hot rolling and cold drawing. The hot rolling process is to heat the steel billet and then roll it to obtain steel pipes of different specifications; the cold drawing process is to heat the steel billet and then perform perforation, tube drawing and other processes to finally obtain the required steel pipe.

a. Hot rolled (extruded) seamless steel tube: round tube billet → heating → piercing → three-roll cross rolling, continuous rolling or extrusion → tube removal → sizing (or reducing) → cooling → straightening →Hydrostatic test (or flaw detection) → marking → storage

b. Cold drawn (rolled) seamless steel tube: round tube blank→heating→perforation→heading→annealing→pickling→oiling (copper plating)→multi-pass cold drawing (cold rolling)→blank tube→heat treatment→Straightening→hydrostatic test (flaw detection)→marking→warehousing

(2) Application:

① General boiler seamless pipes are mainly used to make water wall pipes, boiling water pipes, superheated steam pipes, superheated steam pipes for locomotive boilers, large and small smoke pipes and arched brick pipes.

② High-pressure boiler tubes are mainly used to manufacture superheater tubes, reheater tubes, air guide tubes, main steam tubes, etc. of high-pressure and ultra-high-pressure boilers.

Boiler seamless steel tube adopts steel grade:

(1) High-quality carbon structural steel grades are 20G, 20MnG, and 25MnG.

(2) Alloy structural steel grades 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 12Cr3MoVSiTiB, etc.

(3) The commonly used 1Cr18Ni9 and 1Cr18Ni11Nb boiler tubes with rust and heat-resistant steels should be subjected to hydrostatic tests, flaring and flattening tests one by one in addition to ensuring chemical composition and mechanical properties. Steel pipes are delivered in heat-treated condition.

In addition, there are certain requirements for the microstructure, grain size and decarburization layer of the finished steel pipe.

The production process of high-pressure boiler tubes varies with different steel types.

Taking pearlitic chromium molybdenum vanadium steel as an example, the production process characteristics of boiler tubes are:

(1) The tube blank should be peeled, and the peeling amount is usually 5mm;

(2) Due to the hard steel, the tube blank is often cut or sawed with oxygen;

(3) Since the thermal conductivity of chrome-molybdenum-vanadium steel is lower than that of carbon steel, the heating rate should be slightly slower, the heating temperature is 1120-1180°C, and the piercing temperature is 1100-1160°C;

(4) This type of steel has good plasticity and low deformation resistance in the range of 1000-1100 ° C, so the perforation performance is better, and the deformation parameters can be selected according to medium carbon steel or alloy steel (such as 30CrMnSiA);

(5) After rolling, the steel pipe should be normalized and tempered. The normalizing temperature is 950-980°C, the tempering temperature is 730-750°C, and the holding time is 2-3 hours;

(6) The dimensional tolerance of the steel pipe is relatively strict to ensure the butt joint welding; the length of the pipe is as long as possible to reduce the number of welding joints.

High pressure boiler tube performance requirements:

High-pressure boiler tubes need to have high strength, high pressure resistance, high corrosion resistance and other performance requirements. In high temperature and high pressure environments, the mechanical properties and corrosion resistance of steel pipes will be seriously affected, so special materials and processes need to be used to ensure their performance requirements. For example, stainless steel materials and high-precision welding processes are used.

Application areas:

High-pressure boiler tubes are widely used in electric power, chemical industry, petroleum, pharmaceutical and other fields.

1. In the power industry, high-pressure boiler tubes are mainly used to manufacture boilers, pressure vessels and other equipment;

2. In the chemical and petroleum industries, high-pressure boiler tubes are mainly used to transport high-temperature, high-pressure, and highly corrosive fluids;

3. In the pharmaceutical industry, high-pressure boiler tubes are mainly used for the preparation of high-purity drugs and high-precision experimental equipment.

Market expectation:

With the continuous development of industrial production, the market demand for high-pressure boiler tubes is also growing. In the next few years, the high-pressure boiler tube market will show the following trends:

1. Market competition intensifies: With the increase of domestic high-pressure boiler tube companies and the improvement of technical level, market competition will become increasingly fierce. Enterprises need to continuously improve product quality and technical level, and strengthen brand building and marketing to improve competitiveness.

2. Growth in demand for high-end products: With the upgrading of industrial production and the development of high-end manufacturing, the demand for high-end high-pressure boiler tube products will continue to grow. Enterprises need to increase investment in technology research and development and innovation, and actively develop new products and technologies to meet market demand.

3. Increased environmental protection and energy saving requirements: With the improvement of environmental protection and energy saving awareness, the environmental protection and energy saving requirements for high-pressure boiler tubes will also become higher and higher. Enterprises need to strengthen technological research and application in environmental protection and energy conservation, and actively promote energy-saving, emission reduction and environmentally friendly products.

Read more: Seamless Mechanical Steel Tubing