Factors Affecting the Polishing Performance of Stainless Steel Elbows

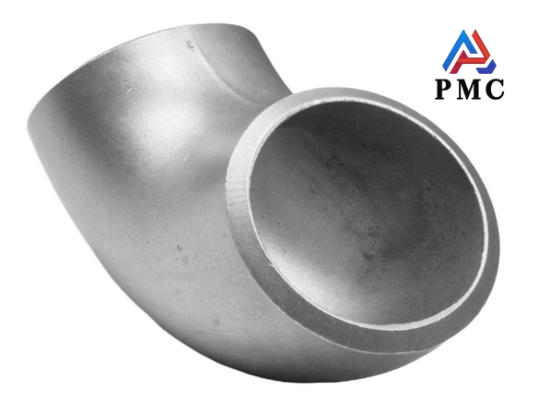

Stainless steel elbows, as extremely critical components in piping systems, are highly favored for their excellent performance. It is mainly made of stainless steel, common ones are 304 stainless steel, 316 stainless steel, etc. It has high strength and good toughness, and can withstand greater pressure and impact, ensuring the stable operation of the pipeline system. It has strong corrosion resistance and performs well in corrosive media such as acid, alkali, and salt water. For example, in marine engineering, seawater is highly corrosive. Stainless steel elbows can work stably for a long time due to their corrosion resistance, greatly extending the service life of the pipeline system.

Moreover, food-grade stainless steel elbows meet hygiene standards and are harmless. They are widely used in food processing and pharmaceutical industries, effectively avoiding the risk of product contamination. Because of their smooth surface and not easy to rust, they are not only beautiful but also reduce maintenance costs. However, the polishing performance of stainless steel elbows is affected by many factors. Understanding these factors will help us better play the performance advantages of stainless steel elbows and meet the use requirements of different scenarios.

1. The strength of the material

The material hardness of the stainless steel elbow has a significant impact on the polishing performance. If the hardness of the material is too low, the key step of polishing will be difficult. This is like using soft materials to polish, it is difficult to make the surface present the ideal gloss. For example, some low-hardness stainless steel materials are still difficult to achieve a high gloss effect after long-term, high-intensity polishing operations. The high hardness enables the material to better withstand the force and friction of polishing during the polishing process, making it easier to be polished and achieve the ideal polishing effect, just like a hard gem that can shine brightly after careful polishing.

2. Surface "defects"

If there are original defects on the surface of the stainless steel elbow, such as scratches, pitting, over-pickling, etc., it will directly affect the polishing performance. Scratches are like grooves carved into the surface. During polishing, these scratches are difficult to completely eliminate, so that obvious marks can still be seen on the polished surface, interfering with the overall flatness and glossiness. Pitfalls are like small pits on the surface. During the polishing process, it is difficult to make these uneven areas smooth. They will hinder the uniform reflection of light and cause uneven gloss. However, excessive pickling of stainless steel elbows will show signs of corrosion on the surface. The surface structure after corrosion has changed and become rough, making it difficult to restore to an ideal smooth state by polishing.

3. The “side effects” of stretching

In the processing of stainless steel elbows, drawing is a common process, but during deep drawing, small black spots will appear on the surface of the area with the largest deformation. These small black spots are like "stumbling blocks" on the polishing road, which will seriously damage the overall polishing effect.

From a microscopic perspective, the internal structure of the material changes during the stretching process, and stress concentration in local areas causes the crystal structure to deform, which in turn produces small black spots. These small black spots increase the surface roughness, causing light to diffusely reflect on its surface, making it difficult to form a uniform and bright luster. At the same time, these small black spots and tiny wrinkles (RIDGING) caused by stretching will also affect the BQ of the stainless steel elbow, reduce its polishing performance, and make the surface of the elbow that could have been bright as new become obviously flawed.

Conclusion

In summary, the factors that affect the polishing performance of stainless steel elbows mainly include material hardness, original surface defects and the influence of stretching processing. The hardness of the material determines the difficulty and effect of polishing. Surface defects such as scratches and pitting directly destroy the basis of polishing, while small black spots and wrinkles produced during the stretching process interfere with the final polishing quality. When producing and processing stainless steel elbows, only by strictly controlling these factors and starting from material selection, processing technology and other aspects can the polishing performance of stainless steel elbows be effectively improved, so that they can fully play their role in the pipeline system and meet the needs of various industries for high-quality stainless steel elbows.

Read more: Common Standards for Stainless Steel Elbows