ERW Pipe vs Seamless Cost

"ERW steel pipe" is Electric Resistance Welding, abbreviated as ERW. It is used to transport oil, natural gas and other vapor and liquid objects. It can meet various requirements of high and low pressure. It currently plays a pivotal role in the field of transportation pipes in the world.

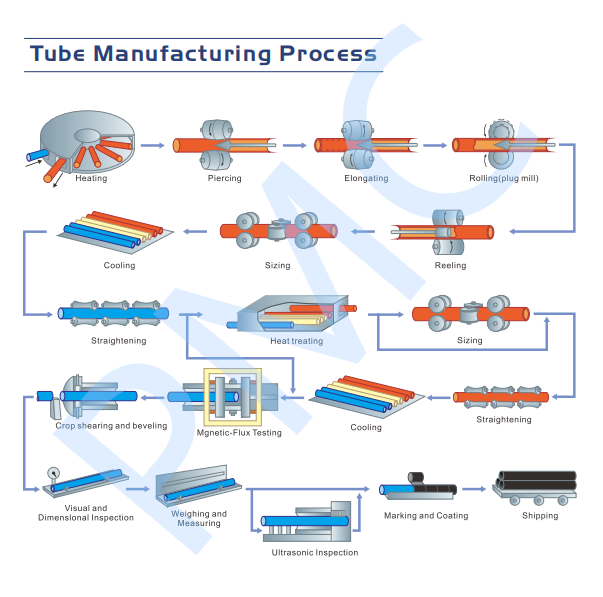

1. Different molding methods

The seamless steel pipe is a steel pipe perforated from a whole round steel without welds on the surface.

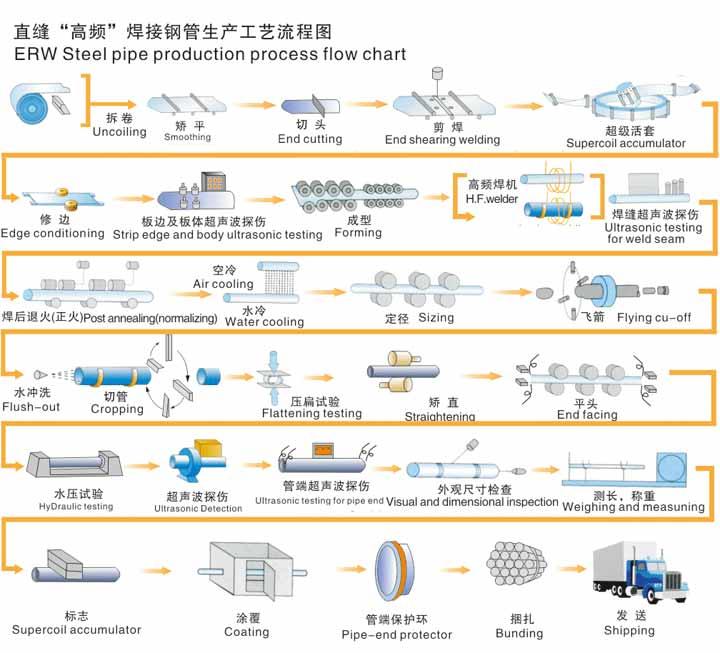

ERW steel pipe refers to a steel pipe that is bent and deformed into a round shape by a steel strip or a steel plate, and then welded to a steel pipe with seams on the surface. The welding method of ERW steel pipe is high-frequency induction heating, which uses high-frequency induction current to heat the edge of the formed coil, and uses squeeze rollers for extrusion welding.

Different production processes have different impacts on costs. The production process of seamless steel pipes is precise and the cost is high, so the price is relatively expensive; while the production process of welded steel pipes is relatively simple and the price is more affordable.

2. Different quality requirements

The quality requirements of seamless steel pipes are relatively high, and it is necessary to ensure that there are no internal defects, a smooth appearance, and no burrs. However, due to the limitations of the production method, it is difficult to avoid defects such as cracks and pores in the welded parts of ERW welded steel pipes. High-quality seamless steel pipes require higher raw material and precision processing costs, and the price is correspondingly higher.

3. Different price

The price of seamless steel pipe is more expensive than ERW steel pipe and the quality is better. The price of seamless steel pipes of the same specification is generally about 30% higher than that of welded pipes, and the price difference for large diameters is even greater. The required stress of seamless steel pipes can be much higher, and welded steel pipes are generally about 10Mpa, so seamless steel pipes are more expensive.

4. Different service life

Seamless steel pipes have higher strength indicators such as compression resistance and tensile strength than ERW welded steel pipes, and have a longer service life.

Seamless steel pipes: general-purpose seamless steel pipes are rolled from ordinary carbon structural steel, low-alloy structural steel or alloy structural steel, and have the largest output. They are mainly used as pipelines for conveying fluids or manufacturing structural parts and mechanical parts, such as oil drills. Rods, automobile drive shafts, bicycle frames, and steel scaffolds used in building construction are made of steel pipes to make ring parts, which can improve material utilization, simplify manufacturing procedures, and save materials and processing man-hours.

ERW steel pipe: ERW longitudinally welded pipe is mainly used in water supply engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, and urban construction. For liquid transportation: water supply and drainage. For gas transportation: coal gas, steam, liquefied petroleum gas. For structural purposes: as piling pipes and bridges; pipes for docks, roads, and building structures.

ERW straight seam welded pipes are generally used as wire casings in the power industry. Performance characteristics: 100% ultrasonic testing of the base material to ensure the internal quality of the pipe body; no uncoiling-disc shearing process, base material pressure pit , Less scratches; After the stress is eliminated, the finished pipe basically has no residual stress; the weld seam is short, and the probability of defects is small; it can conditionally transport the moist sour natural gas; After the diameter is expanded, the geometrical size of the steel pipe is high; welding It is carried out in a straight line in the horizontal position after the forming is completed. Therefore, the control of staggered edges, slits, pipe diameter and circumference is better, and the welding quality is excellent.

6. Market demand

Seamless steel pipes are widely used in petroleum, chemical industry, machinery, rail transit and other fields. Due to the particularity of applications and quantity requirements, the price of seamless steel pipes is relatively high. Affected by market competition and market demand, the price of ERW steel pipes is relatively low.

Overall, seamless steel pipes are more expensive than ERW welded steel pipes. Because the production process and quality requirements of seamless steel pipes are higher, and the market demand is also more specialized. But this does not mean that ERW steel pipes are cheaper in all cases, and they need to be considered comprehensively based on specific circumstances.

Tips: ASTM A53 covers seamless and welded steel pipe with nominal wall thickness. The surface condition is usually black and hot-dipped galvanized. ASTM A53 is produced mainly for pressure and mechanical applications, and is also used for transport of steam, water, gas line pipes.

A53 Grade B Seamless is our most polar product under this specification and A53 pipe is commonly dual certified to A106 B Seamless pipe.