Carbon Steel Tube Production Process and International Standards

1) Production process of carbon steel tube

1. Raw material preparation

The main raw material of carbon steel tube is carbon steel, usually using hot-rolled steel plate or cold-rolled steel plate produced by steel mills as raw material. In the raw material preparation process, the steel plate needs to be cut, heat treated and other processes to meet the requirements of steel pipe production.

2. Tube blank heating

The cut steel plate is heated, usually by high-frequency induction heating or flame heating. The purpose of heating is to make the steel plate reach a certain temperature for the next step of forming process.

3. Tube blank forming

The heated steel plate is formed by a forming machine. There are two common forming methods, one is cold rolling forming, that is, the steel plate is bent into a tubular shape; the other is hot rolling forming, that is, the steel plate is extruded into a tubular shape at high temperature. The formed tube blank needs to be cooled and straightened.

4. Welding process

There are two main welding processes for carbon steel tubes, one is resistance welding, that is, the two ends of the tube blank are heated by electric current to melt and connect them together; the other is arc welding, that is, the two ends of the tube blank are heated by an arc, Let it melt and join together. The welded tube blanks need to remove welding slag and surface treatment.

5. Pipe processing

The welded tube blanks are processed by cutting, flaring, trimming and other processing techniques to meet the requirements for the size and shape of the tubes in different applications.

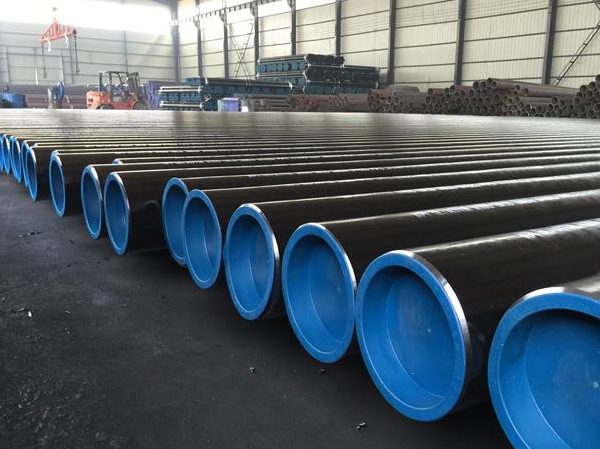

6. Pipe surface treatment

The surface of the pipe is treated with rust removal and painting to improve the anti-corrosion performance and aesthetics of the pipe.

7. Pipe quality inspection

The physical properties, chemical composition, and dimensional accuracy of the produced pipes are tested to ensure that the quality of the pipes meets the standard requirements.

2) Standards for carbon steel tubes

1. International standard

The international standards for carbon steel tubes mainly include ASTM (American Society for Testing and Materials) standards, DIN (German Institute for Standardization) standards, JIS (Japanese Industrial Standards) standards, etc. These standards specify the requirements for the material, physical properties, chemical composition, and dimensional accuracy of carbon steel pipes.

2. Standard

The standards of carbon steel pipes are standards formulated according to their own needs, such as China's GB/T (standard) standard. Standards usually refer to international standards and are adjusted and improved according to domestic actual conditions.

3. Industry standard

The industry standards for carbon steel tubes are those established by relevant industry organizations or associations, such as API (American Petroleum Institute) standards for oil line pipes. Industry standards usually address the needs of specific application areas, and put forward more specific requirements for the performance and quality of carbon steel tubes.

In conclusion:

The production process and standards of carbon steel tubes are very important to ensure the quality and performance of steel pipes. Through reasonable production technology and strict standard requirements, carbon steel tubes of good quality can be produced to meet the needs of various fields. When using carbon steel tubes, we should choose products that meet the requirements of the standards, and install and use them in accordance with relevant regulations to ensure their safety and reliability.

Go here to learn more about "What are the Classifications and Applications of Carbon Steel Seamless Tubes?"