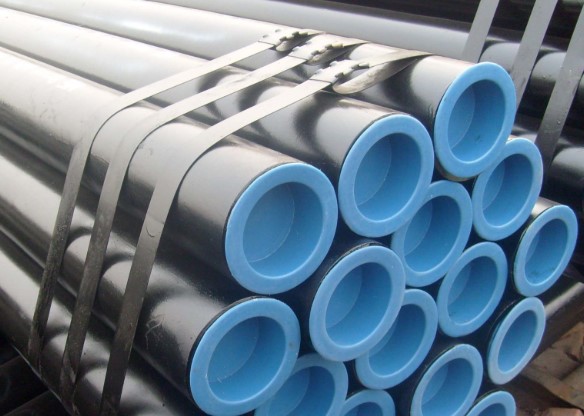

ASTM A53 Pipe Specifications

ASTM A53 is a general carbon steel pipe standard developed by the American Society for Testing and Materials (ASTM). It is applicable to seamless and welded steel pipes and is widely used to transport fluids such as water, steam, and air. It can also be used as pipes for mechanical structures. This type of steel pipe is made of low carbon steel as the main material, with moderate strength and good machinability. According to the production process, it is divided into seamless steel pipe and welded steel pipe. Different types have different weld seam treatments, but the core material performance is the same.

ASTM A53 Pipe Specifications

ASTM A53 steel pipes have a variety of sizes and specifications, mainly divided into seamless steel pipes and welded steel pipes, and divided into multiple grades (such as Grade A, Grade B) according to different application scenarios. The following are its core size parameters and common specifications:

1. Outer diameter range

The outer diameter of ASTM A53 steel pipes ranges from 1/8 inch (about 6.35mm) to 24 inches (about 609.6mm), which are divided into three series:

Series I: mainly standard specifications, such as 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2", 2", etc., suitable for general industrial pipelines.

Series II: non-standard but commonly used specifications, such as 2-1/2", 3", 4", 5", 6", etc., often used in building structures or high-pressure fluid transportation.

Series III: large-diameter specifications (≥8"), such as 8", 10", 12", 14", 16", 18", 20", 24", etc., mainly used in municipal engineering or large industrial projects.

2. Wall thickness and wall thickness grade

Wall thickness is usually expressed as **Nominal wall thickness (Schedule)**, and common grades include:

Sch 40: The most commonly used medium wall thickness, suitable for most low-pressure to medium-pressure scenarios (such as tap water pipes).

Sch 80: Thicker wall thickness, suitable for high-pressure systems (such as steam pipes, compressed air pipes).

Sch 160: Extra thick wall, used for extremely high pressure or highly corrosive environments.

XXS (Extra Extra Strong): Double thickening, only used for small diameter pipes (such as 1/2" or less).

3. Length standard

Fixed length: usually 6 meters (about 19.69 feet) or 12 meters (about 39.37 feet), can be customized according to needs.

Unfixed length: generally ranges from 4-12 meters, subject to the specific production of the steel plant.

4. Special Dimensions and Tolerances

5. Non-standard Dimensions: Non-standard outer diameter or wall thickness can be produced provided that other performance requirements of ASTM A53 are met.

6. Tolerance Requirements: The outer diameter tolerance is usually ±0.75% (for steel pipes ≤16") or ±1.0% (>16"); the wall thickness tolerance is ±12.5%.

Mechanical properties of astm a53 steel pipe

The mechanical properties of ASTM A53 steel pipes are the core indicators of their adaptation to industrial scenarios. The standard has clear requirements for steel pipes of different types (seamless, welded) and grades (Grade A, Grade B), as follows:

1. Tensile strength

Grade A: ≥330 MPa (approximately 48,000 psi)

Grade B: ≥415 MPa (approximately 60,000 psi)

(Note: The strength of the weld area of the welded steel pipe must be consistent with that of the parent material and is not allowed to be lower than the above standards)

2. Yield strength

3. Grade A: ≥205 MPa (approximately 30,000 psi)

4. Grade B: ≥240 MPa (approximately 35,000 psi)

5. The yield strength determines the steel pipe's ability to resist deformation when subjected to stress. The higher yield strength of Grade B makes it suitable for slightly higher pressure scenarios.

3. Elongation

Measures the plastic deformation capacity of steel pipes and is related to the size of the steel pipe:

For steel pipes with an outer diameter ≤168.3mm (6.625 inches): ≥20%

For steel pipes with an outer diameter >168.3mm: ≥15%

Higher elongation ensures that the steel pipe is not easy to break during bending, flaring and other processing.

Applications of ASTM A53 pipe

1.Construction: the pipeline underneath, the groundwater, and the hot water transportation.

2.Mechanical processing, bearing sleeves, processing machinery parts, etc.

3. Electrical: Gas delivery, Hydroelectric power fluid pipeline

4.Anti-static tubes for wind power plants, etc.

Read more: ASTM A53 Carbon Steel Seamless Pipe Specifications