What are the Safety Measures for Oil Pipelines?

What are the types of oil pipelines?

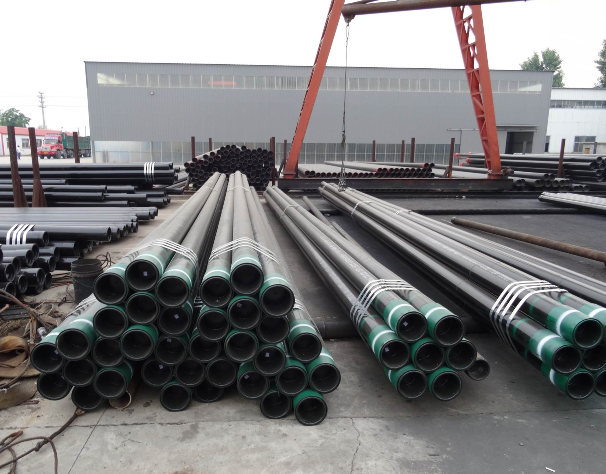

Generally speaking, there are two types of oil pipelines: carbon steel pipes and oil-resistant rubber hoses. Many of the fixed oil pipelines we see now mostly use carbon steel pipes, while oil-resistant steel pipes play an important role in the temporary loading and unloading of active parts of oil transportation facilities. In carbon steel pipes, it can also be divided into seamless steel pipes and welded steel pipes according to different manufacturing methods, and seamless steel pipes are also divided into hot rolled and cold drawn.

What are the safety measures for oil pipelines?

Oil pipeline is an important part of modern energy transmission, it carries a large amount of oil and natural gas resources, so safety issues are particularly important. In order to ensure the safe operation of petroleum oil pipelines, a series of strict safety measures need to be taken. This article will introduce some common oil pipeline safety measures.

The design and construction of petroleum oil pipelines should follow relevant standards and specifications to ensure the strength, stability and corrosion resistance of pipelines. In the design stage, factors such as transmission distance, transmission capacity, geographical environment and geological conditions need to be considered to determine the appropriate pipeline diameter, thickness and support structure to ensure that the pipeline can withstand the expected pressure and external environment.

2. Regular pipeline monitoring and maintenance.

Oil pipelines require frequent inspections and maintenance to detect and deal with potential problems. Leak detection is the key link. By using high-precision leak detection technologies, such as gas detection, liquid flow meters and smart sensors, pipeline leaks can be detected and located early. In addition, using remote sensing technology and drones and other modern technical means, it is possible to conduct a comprehensive inspection of the pipeline, find out the abnormal condition of the pipeline in time, and take corresponding maintenance measures.

3. Anti-corrosion and heat preservation measures.

Due to the high temperature and corrosiveness of oil and natural gas, oil pipelines need to take measures for anti-corrosion and heat preservation to prolong the service life of the pipeline and ensure safe operation. Common anti-corrosion insulation materials include epoxy coating, polyethylene film, rock wool, etc. These materials can effectively isolate the influence of the external environment and media, and protect the pipeline from corrosion and temperature changes.

4. Emergency response planning and training.

Developing an emergency response plan is the key to ensuring rapid response and action in the event of an emergency. The plan should include procedures for dealing with various accidents such as spills, fires and explosions, specifying responsibilities and action steps. In addition, train relevant personnel to improve their emergency response capabilities and accident handling skills to minimize losses and risks.

5. Safety supervision and regulatory compliance.

The government and relevant regulatory agencies should strengthen the safety supervision of oil pipelines, formulate and implement relevant regulations and standards, and require enterprises to abide by safety regulations and operating procedures. Violations should be punished in accordance with the law to maintain the safety and stability of the entire oil pipeline industry.

6. Environmental awareness and measures.

Oil pipeline transportation may involve some sensitive environmental areas, such as waters, forests and ecological protection areas, so it is necessary to attach great importance to environmental protection. During the design and construction stages, damage and pollution to the environment should be avoided as much as possible, and the pipeline layout should be planned reasonably. During the operation period, an environmental monitoring system should be established to regularly detect and evaluate the environmental impact during transportation, and take corresponding measures to repair and compensate.

7. Information technology application.

With the development of information technology, its application in oil pipeline safety management is becoming more and more important. For example, through the establishment of a remote monitoring system, real-time monitoring and data analysis of pipeline operation status, timely detection of abnormal conditions and take measures. At the same time, big data, artificial intelligence and other technologies are used to predict and evaluate the operational risks of pipelines, and take measures in advance to avoid accidents.

8. International cooperation and experience sharing.

Oil pipeline safety is a global issue, and countries need to strengthen cooperation and experience sharing. Through joint formulation of standards, technical exchanges, and training cooperation, etc., we will promote the improvement of the safety management level of oil and oil pipelines, jointly meet challenges, and ensure the safety and reliability of energy transmission.

To sum up, oil pipeline safety measures cover many aspects, including engineering design, monitoring and maintenance, anti-corrosion and heat preservation, emergency response, regulatory compliance, environmental protection, information technology application, and international cooperation. By taking these measures comprehensively and effectively, the safe operation of oil pipelines can be ensured to the greatest extent and reliable support for energy supply can be provided.

What is the difference between oil tubing and casing pipe? Where is the oil well separately? Is the casing pipe the one that is the outermost layer of the well? Let me help you answer the following:

Tubing and casing pipe are essential tools for oil exploration.

The tubing is a tube that is lowered into the casing of the well when the well is being produced normally. From the well, the oil flows through the oil pipe into the ground and enters the gathering process. In the coal mining well, the combination of oil pipe, sucker rod and deep well pump draws oil to the ground and enters the gathering process.

The casing is a pipe that is lowered into the well after the drilling is completed. The casing and the well wall are cement-sealed, and then the perforating gun is used to align the perforation of the target layer, so that the oil flows through the rock layer, the cement ring, and the casing into the well. At the bottom, enter the tubing and come to the ground. The main role is:

1. Reinforce the well wall to prevent the formation from collapsing;

2. Separate different oil layers and water layers to achieve stratified mining;

3. Easy to implement fracturing, acidification and other measures and maintenance operations;

4. The formation of oil flow channels, with the oil pipe to achieve the purpose of oil recovery.

The order is: after the oil well is laid, the casing is placed, the casing and the well wall are sealed with cement, and the oil pipe is placed in the casing. The oil pipe is equipped with a downhole tool such as an oil packer and a pump. The sucker rod is inserted into the oil pipe, and the sucker rod pulls the piston of the pump to reciprocate up and down. In this way, the oil is pumped to the ground.